Automobile guard plate welding fixture, multi-station welding system and welding method

A welding fixture and welding station technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low production efficiency, inability to guarantee the accuracy of limit fixation, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

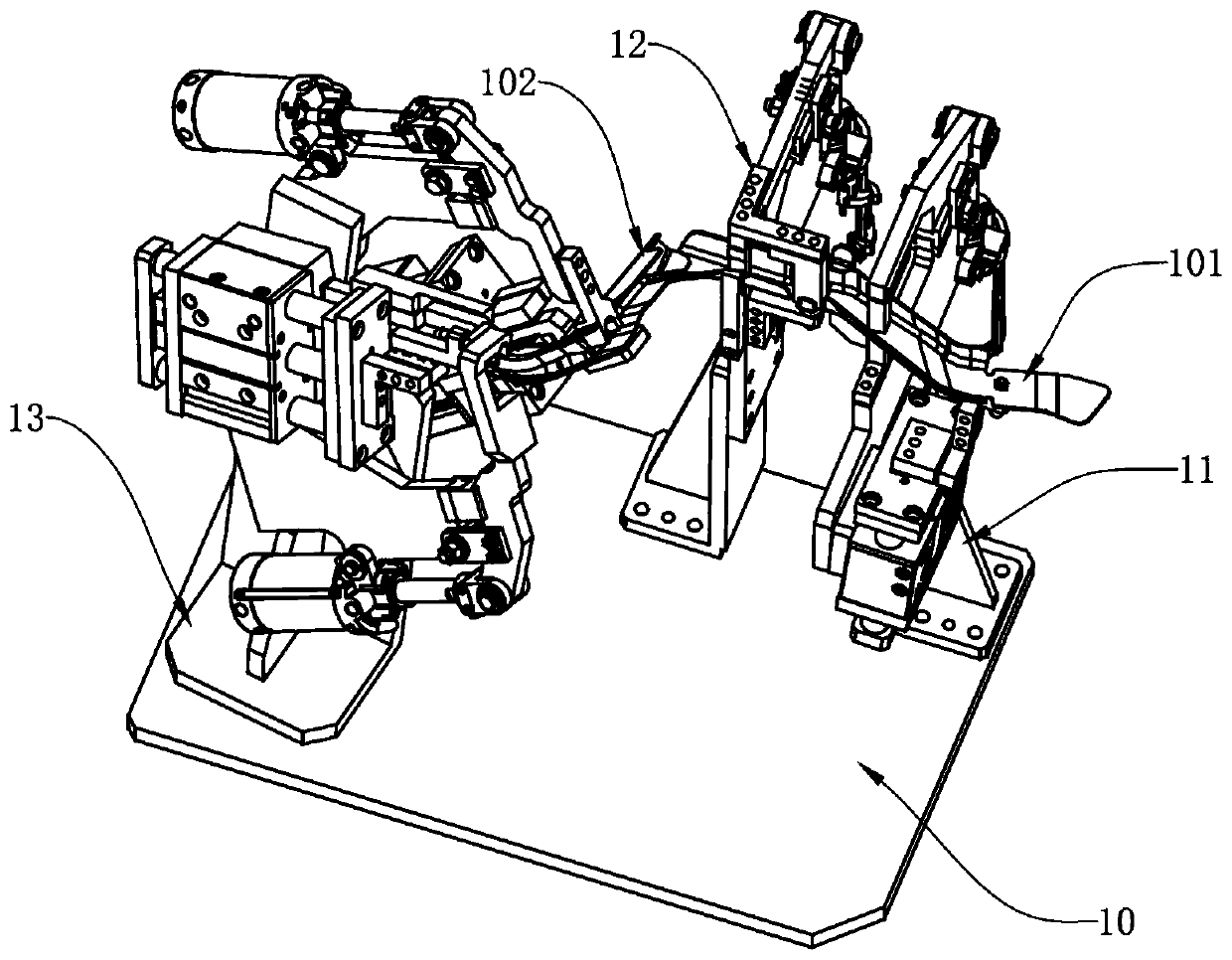

[0052] refer to Figure 1 to Figure 4 , this embodiment provides a welding jig for automobile fenders, which is used to limit and fix two automobile fenders that need to be welded before welding. In this embodiment, the automobile fenders are divided into the first fender before welding 101 and the second guard plate 102, the first guard plate 101 is provided with a first positioning hole and a second positioning hole, and the second guard plate 102 is provided with a third positioning hole and a fourth positioning hole;

[0053] The automobile fender welding fixture comprises a base plate 10, a first fixing module 11, a second fixing module 12 and a third fixing module 13, and the first fixing module 11, the second fixing module 12 and the third fixing module 13 are respectively fixed on the base plate 10 superior;

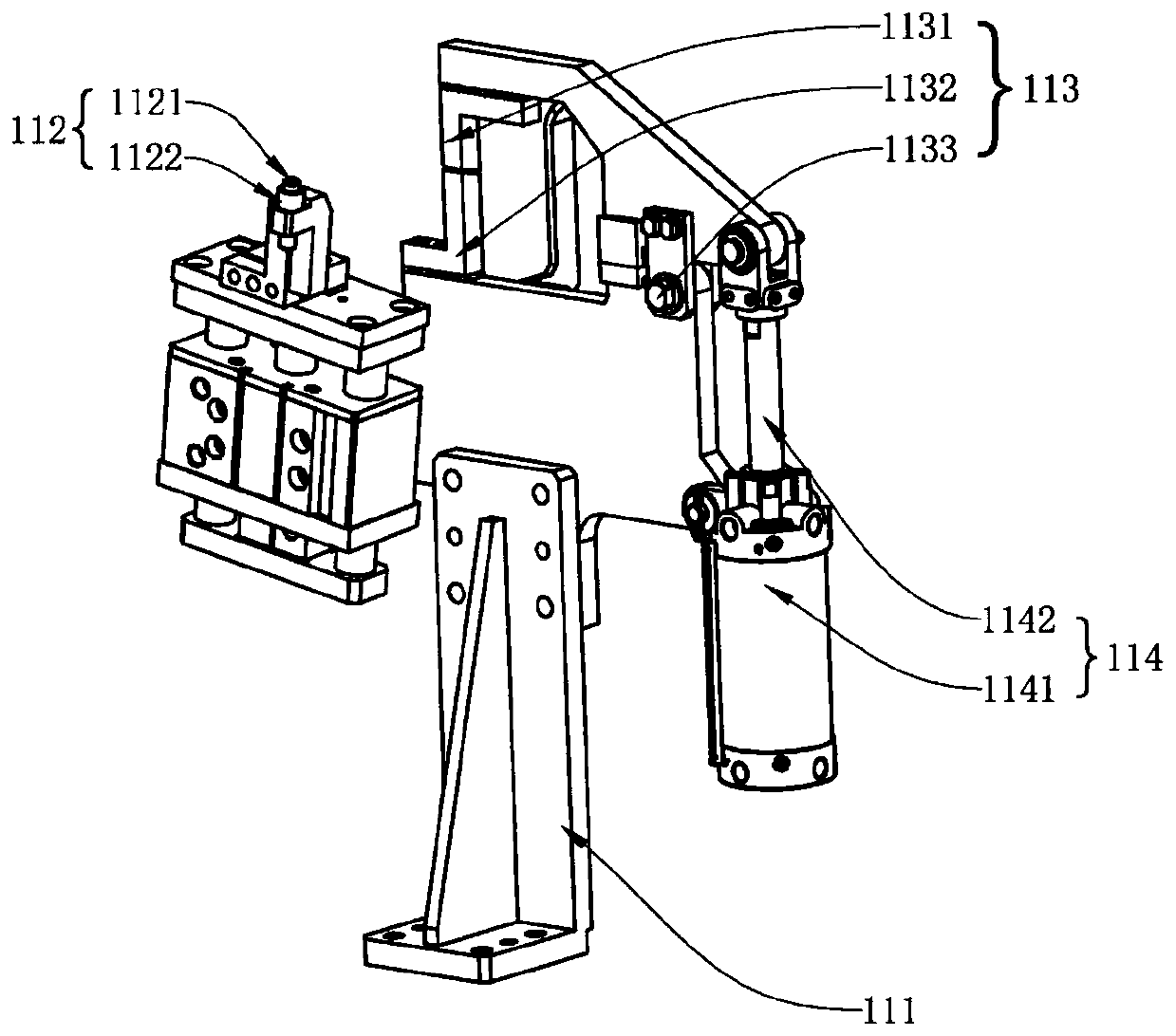

[0054] The first fixing module 11 includes a first support plate 111 fixed on the bottom plate 10, a first column pin 112 for limiting the first guard plate 101...

Embodiment 2

[0071] refer to Figure 5 to Figure 6 , the present embodiment provides a multi-station welding system with a welding jig for an automobile fender, including a welding robot 21, at least two welding stations for placing the welding jig 1 for an automobile fender, a control system 22, and a welding system that is arranged on the welding jig. The outermost working fence 23;

[0072] The welding robot 21 is used to weld the first guard plate 101 and the second guard plate 102, and includes an installation base 211, a horizontal rotation base 212, a welding robot arm group and a welding torch 2139, the installation base 211 is fixed on the ground, and the horizontal rotation base 212 is fixed on the installation base 211, one end of the welding robot arm group is fixed on the horizontal rotation base 212 and can rotate along the horizontal rotation base 212, and the other end is fixed with a Welding gun 2139, the welding robot arm set is composed of at least one welding robot arm...

Embodiment 3

[0087] This embodiment provides a welding method with the multi-station welding system, the method comprising:

[0088] Step S1, fixedly place welding jigs for automobile fenders on at least two welding stations, and respectively prepare and fix the first fender 101 and the second fender 102 on each of the welding jigs for automobile fenders;

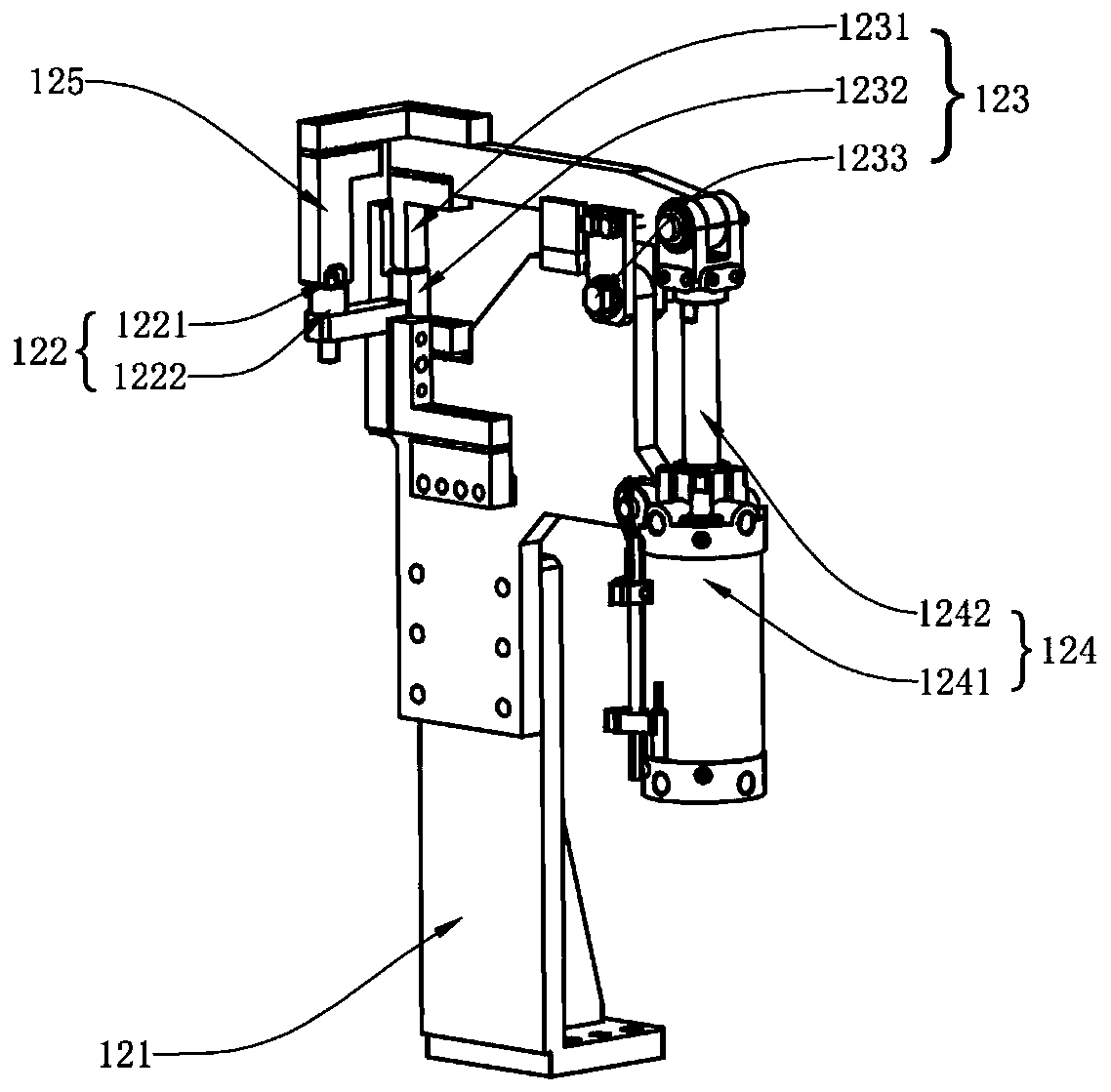

[0089] Step S2, on the automobile fender welding jig, the first fender 101 is limited by the first pin 112 of the first fixing module 11 and the second pin 122 of the second fixing module 12, and the control system 22 is operated Control the first transmission device 114 and the second transmission device 124 for transmission, and push the first clamping upper column 1131 and the second clamping upper column 1231 to turn over, and the first clamping upper column on the side of the first guard plate 101 1131 and the second clamping upper column 1231 are reversed and correspondingly clamp the first guard plate 101 with the first clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com