Automobile cantilever support welding fixture, multi-station welding system and welding method

A cantilever bracket, welding fixture technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of low degree of automation, low stability, low production efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

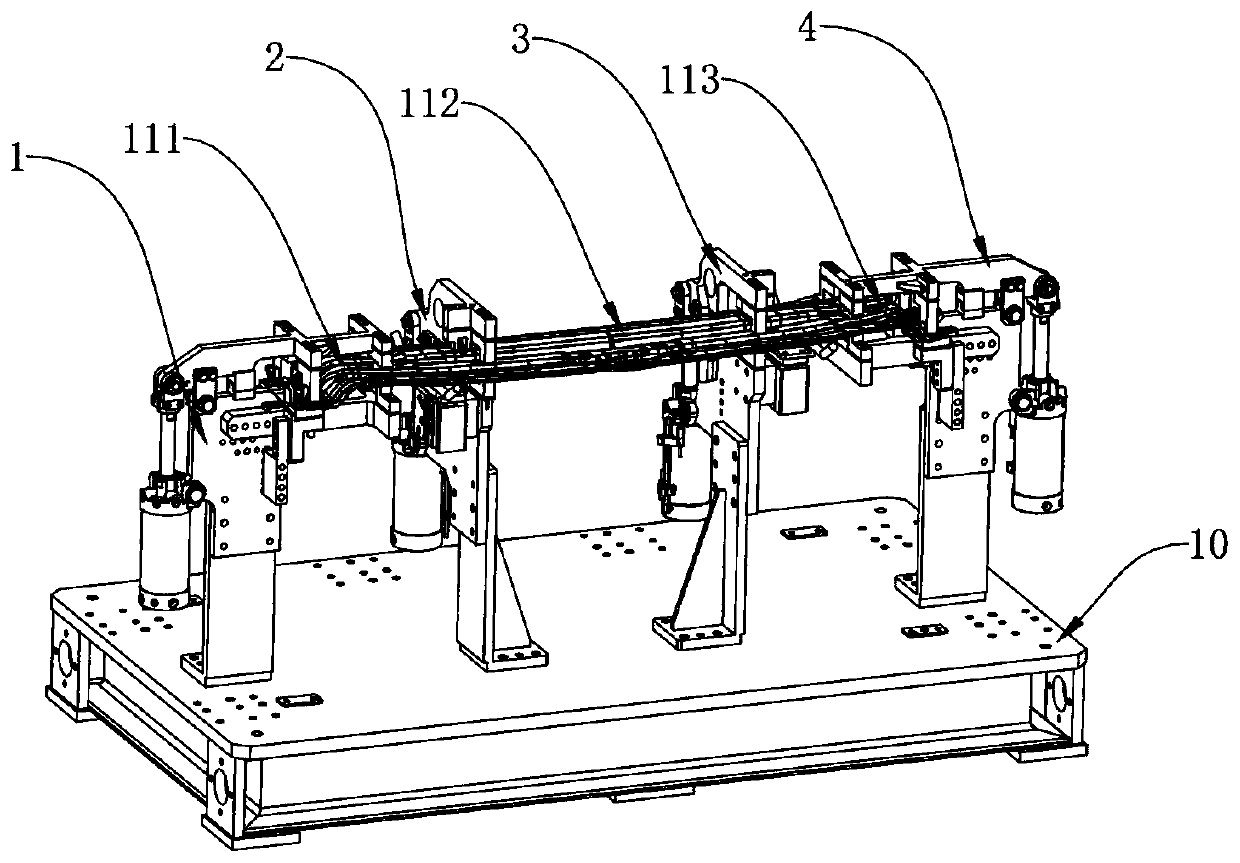

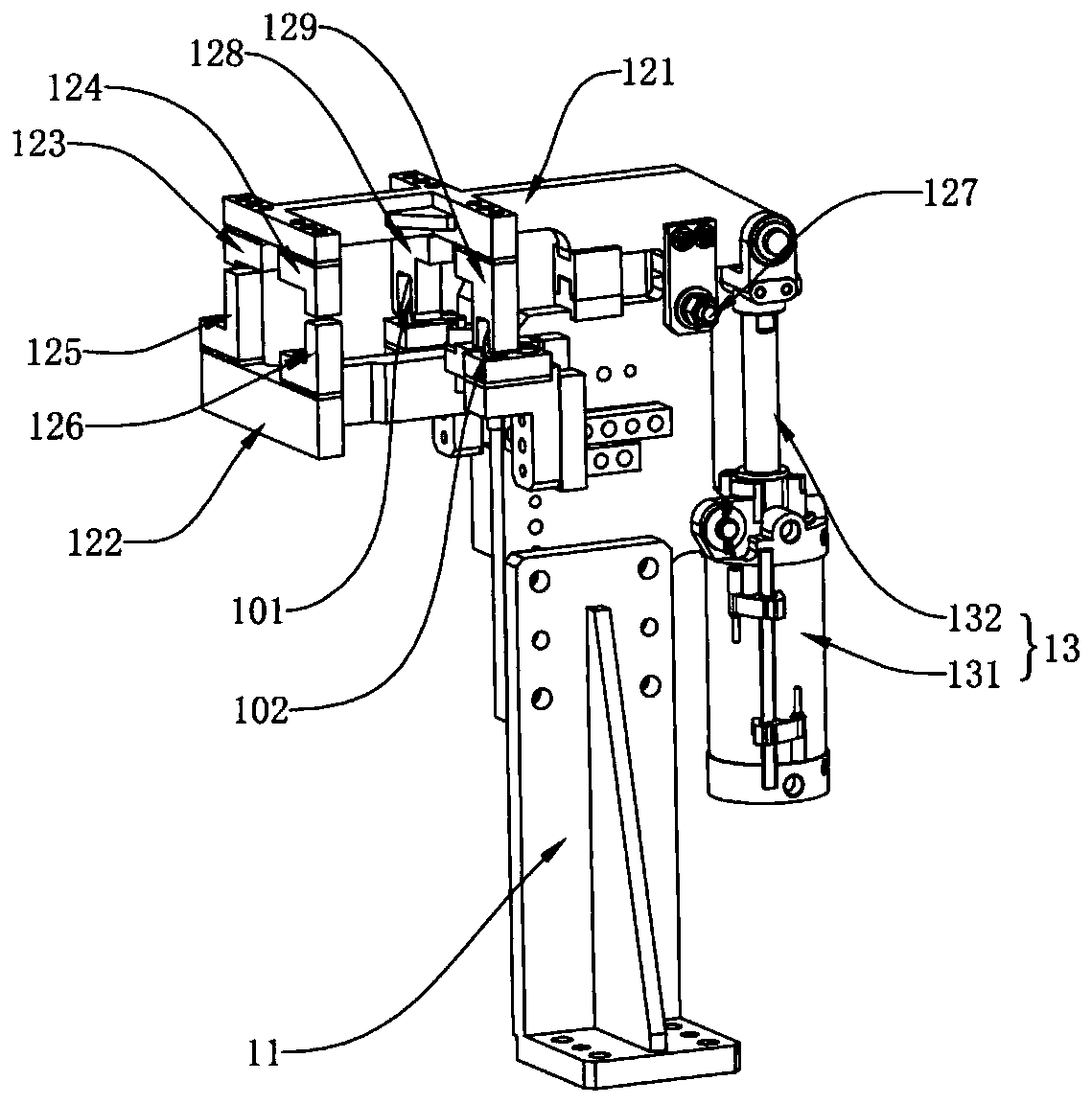

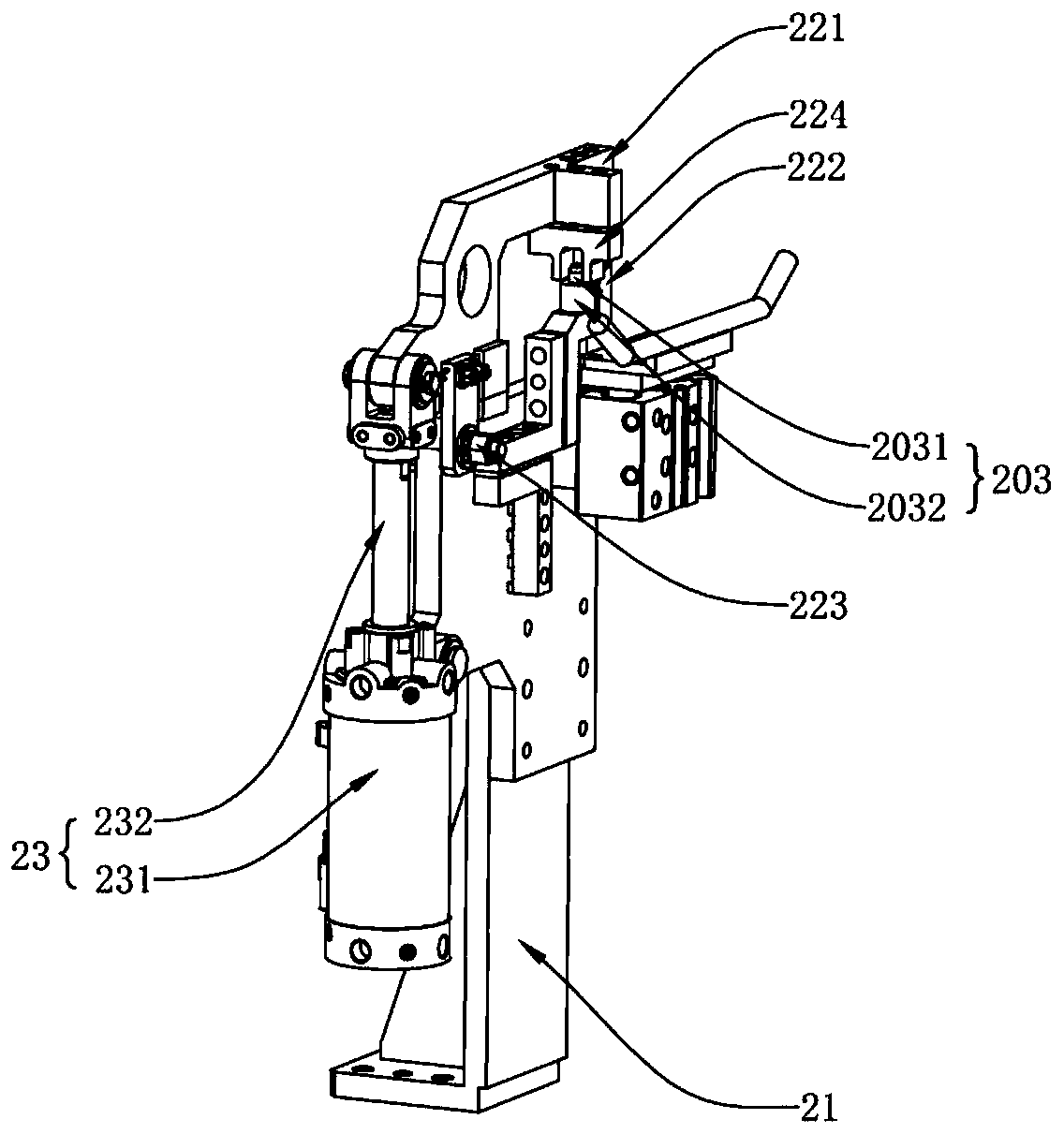

[0056] refer to Figure 1 to Figure 5 , this embodiment provides a welding jig for automobile cantilever brackets, which is used to limit and fix three automobile cantilever brackets that need to be welded before welding. In this embodiment, the automobile cantilever brackets are divided into first cantilever brackets 111, The second cantilever bracket 112 and the third cantilever bracket 113, the first cantilever bracket 111 is provided with the first positioning hole and the second positioning hole, the second cantilever bracket 112 is provided with the third positioning hole and the fourth positioning hole, the third cantilever bracket 113 is provided with a fifth positioning hole and a sixth positioning hole;

[0057] The automobile cantilever bracket welding fixture comprises a base plate 10, a first fixed module 1, a second fixed module 2, a third fixed module 3 and a fourth fixed module 4, the first fixed module 1, the second fixed module 2, and the third fixed module ...

Embodiment 2

[0076] refer to Figure 6 to Figure 8 , the present embodiment provides a multi-station welding system with an automobile cantilever support welding fixture, including a welding robot 51, at least two welding stations for placing the automobile cantilever support welding fixture 100, a control system 53 and a welding system the outermost working fence 54;

[0077] The welding robot 51 is used for welding the first cantilever support 111, the second cantilever support 112 and the third cantilever support 113, including a mounting base 511, a horizontal rotation base 512, a welding robot arm group and a welding torch 514, and the mounting base 511 is fixed on On the ground, the horizontal rotation base 512 is fixed on the installation base 511, one end of the welding robot arm group is fixed on the horizontal rotation base 512 and can rotate along the horizontal rotation base 512, and the other end is fixed to the first cantilever bracket 111, The welding gun 514 for welding th...

Embodiment 3

[0092] This embodiment provides a welding method with the multi-station welding system, the method comprising:

[0093] Step S1, fixedly place the welding jigs for the automobile cantilever brackets on at least two welding stations, and prepare and fix the first cantilever brackets 111, the second cantilever brackets 112 and the third cantilever brackets 113 on each of the automobile cantilever bracket welding jigs;

[0094] Step S2, on the automobile cantilever bracket welding fixture, the first cantilever bracket 111 is limited by the first pin 101 and the second pin 102 of the first fixing module 1, and the second cantilever bracket 112 is passed by the second fixing module The third pin 203 of 2 and the fourth pin 304 of the third fixing module 3 are limited, and the third cantilever bracket 113 is limited by the fifth pin 405 and the sixth pin 406 of the fourth fixing module 4 , so that the first cantilever bracket 111, the second cantilever bracket 112 and the third cant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com