Antistatic film bilateral sweating soldering edge sealing bag forming machine

An anti-static film and hot-melt welding technology, which is applied to household components, household appliances, and other household appliances, can solve the problem of low efficiency of the thermal bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

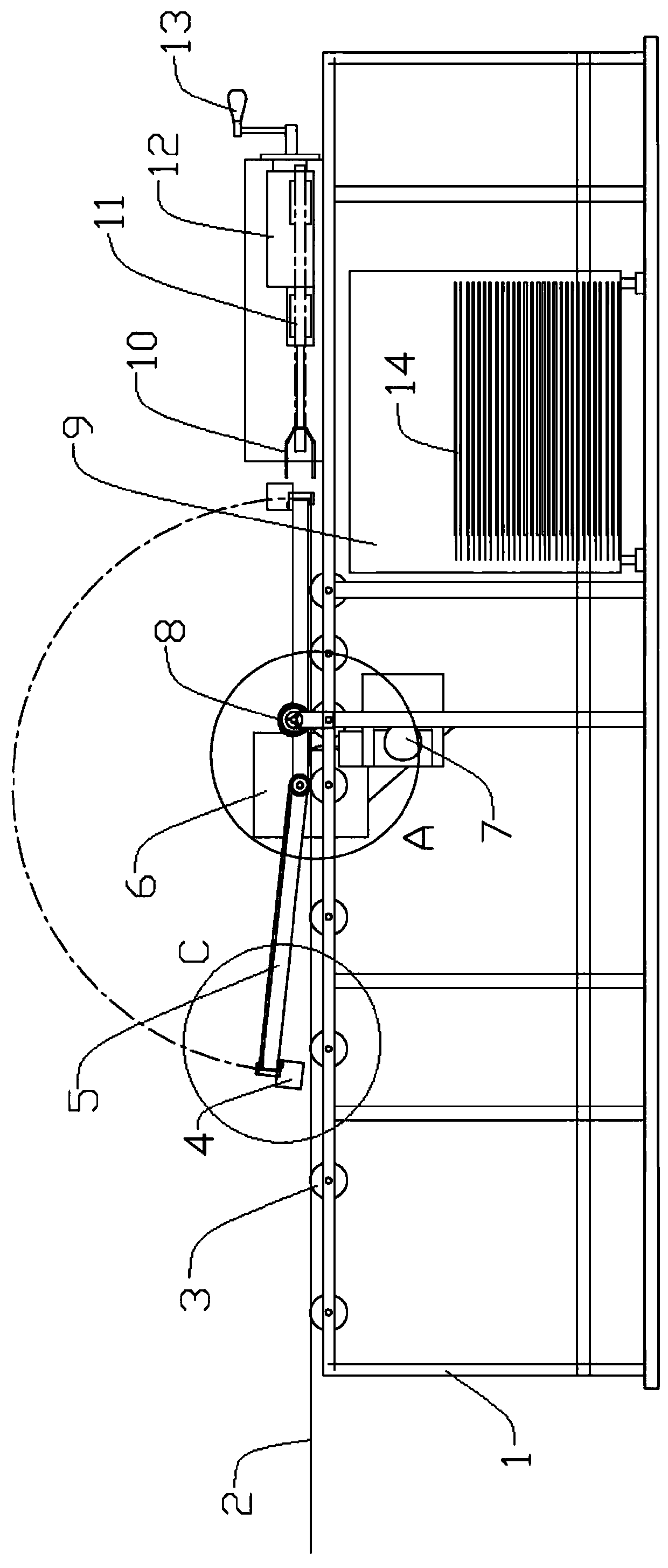

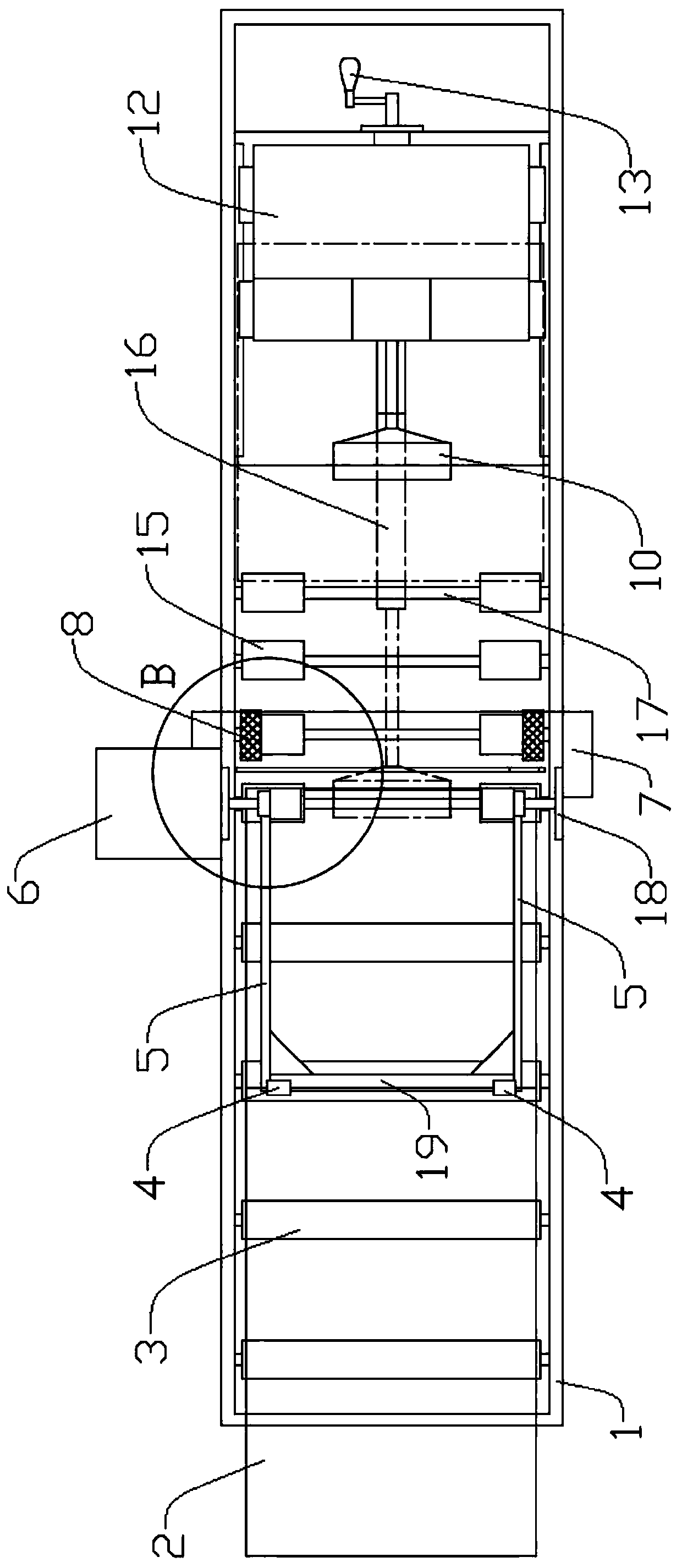

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

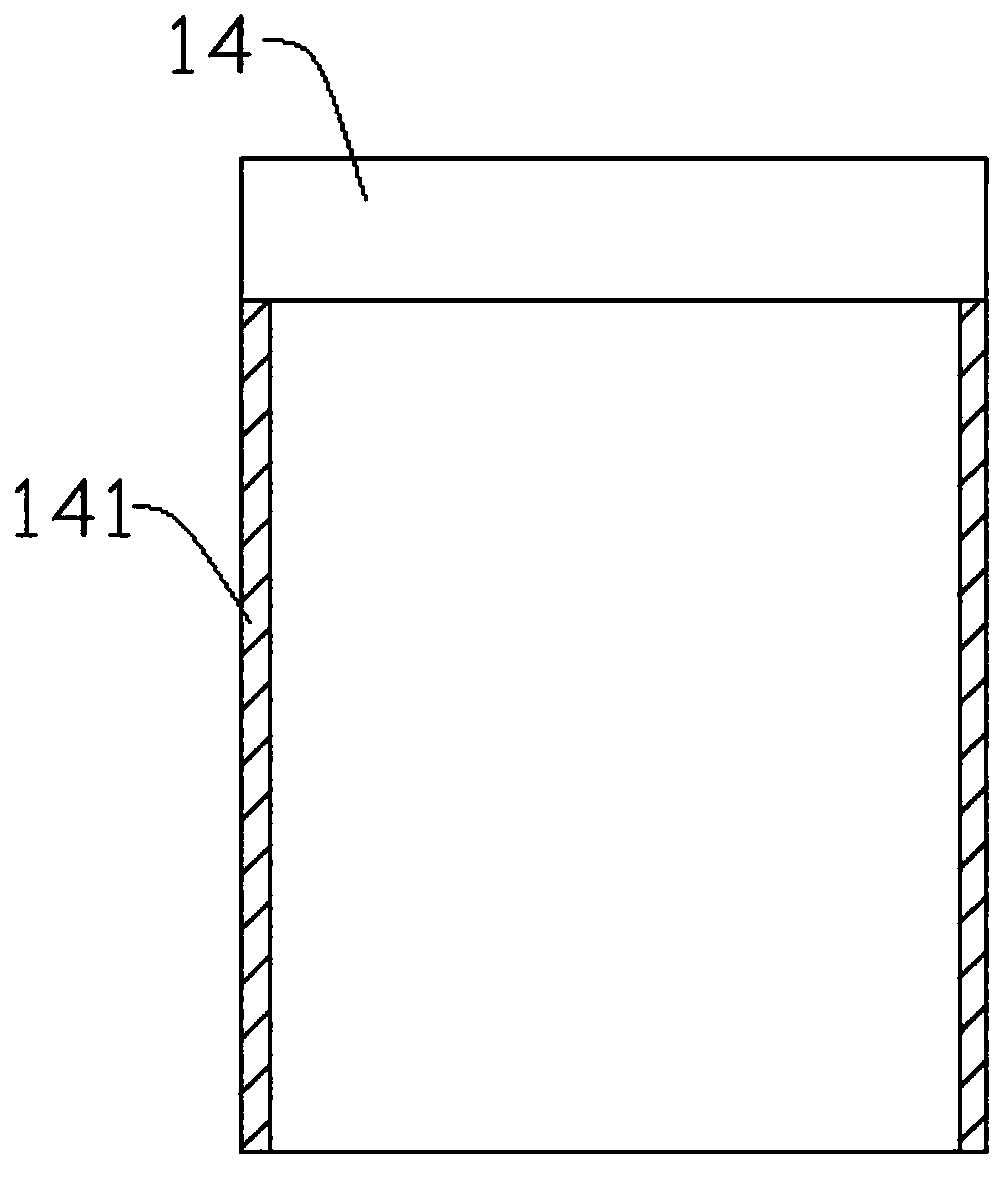

[0024] see Figure 1-6 , this embodiment proposes an antistatic film double-sided heat-melt welding edge-sealing bag forming machine, including a frame 1 with a conveying roller 3, an automatic clamping and folding assembly, a distance-adjustable pulling assembly, a hot-melt welding assembly, Automatic cutting assembly and output box 9.

[0025] Specifically, the antistatic film 2 is unfolded and laid flat on the conveying roller 3 through the feeding roller, and the front edge of the antistatic film 2 is clamped by the automatic clamping and turning assembly, and the conveying roller 3 includes an integrated roller And the split roller, the integrated roller accepts the antistatic film 2 feeding, the split roller includes the transmission shaft 17 and the half rollers 15 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com