Roll change buggy lifting device of galvanization tension leveler

A technology of roll changing trolley and lifting device, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of inability to guarantee roll changing efficiency, discontinuous lifting, production line loss, etc., and achieve reduction The effect of manpower input, saving manpower cost and improving the efficiency of roll changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

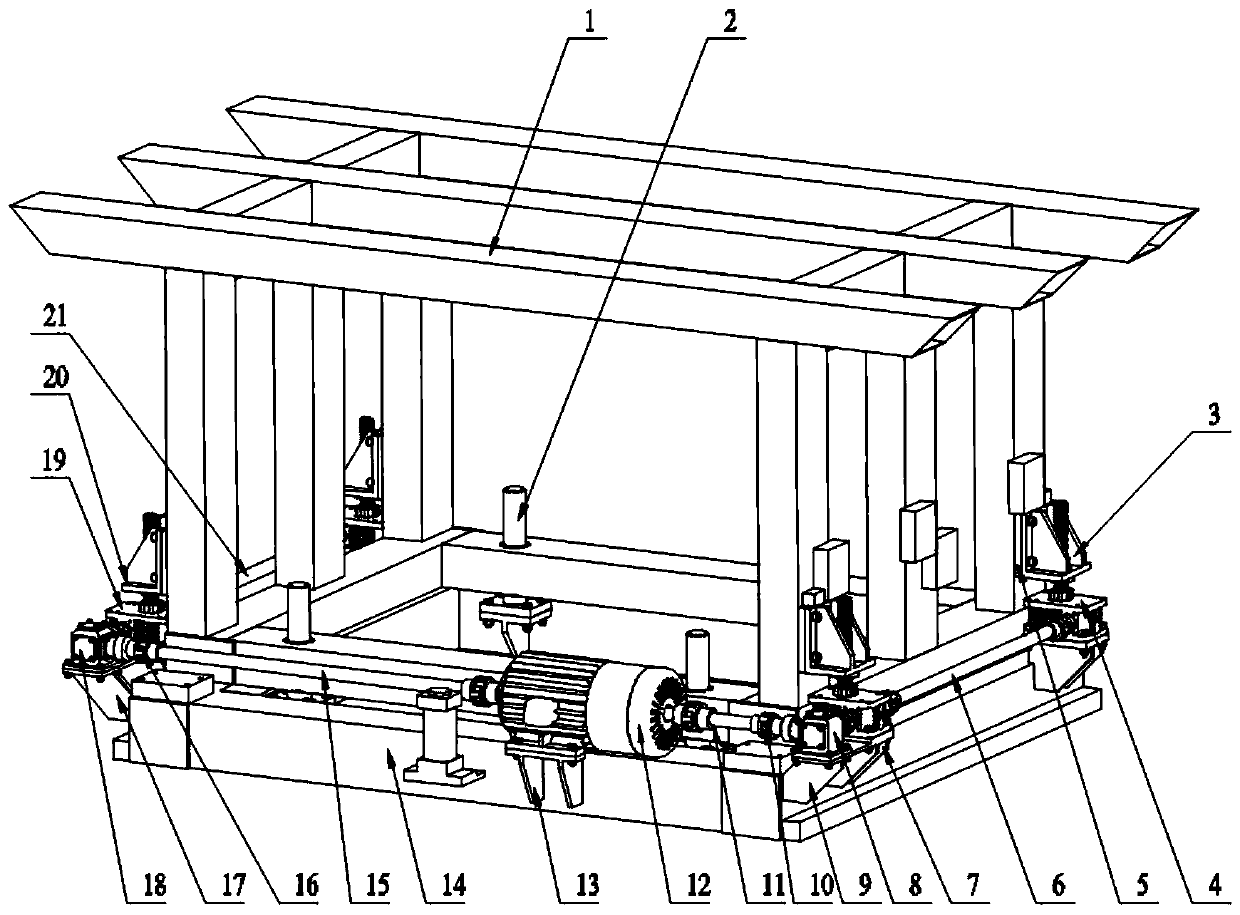

[0023] A galvanized pulling and leveling machine roller changing trolley lifting device includes a base 14, and its innovation lies in that a motor support base 13 is arranged at the front end of the base, and a bidirectional output motor 12 is fixedly installed on the motor support base. The left end of the base is provided with a left commutator fixing seat 17 and two left elevator fixing seats 20 , the left commutator 18 is installed on the left commutator fixing seat, and the left elevator 19 is installed on the two left elevator fixing seats. , the left output shaft 15 of the bidirectional output motor is connected to the left commutator through a left coupling 16, the left commutator is connected to the left lift, and the left lift is connected throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com