Electromagnetic compound vibration type material layering device and use method thereof

An electromagnetic composite and layering device technology, which is applied to chemical instruments and methods, solid separation, and filtration and screening, can solve the problems of unsatisfactory vibration and layering effects of mixed particles, insufficient mixing and collision, and low work efficiency. Small structure, improved layering efficiency, and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

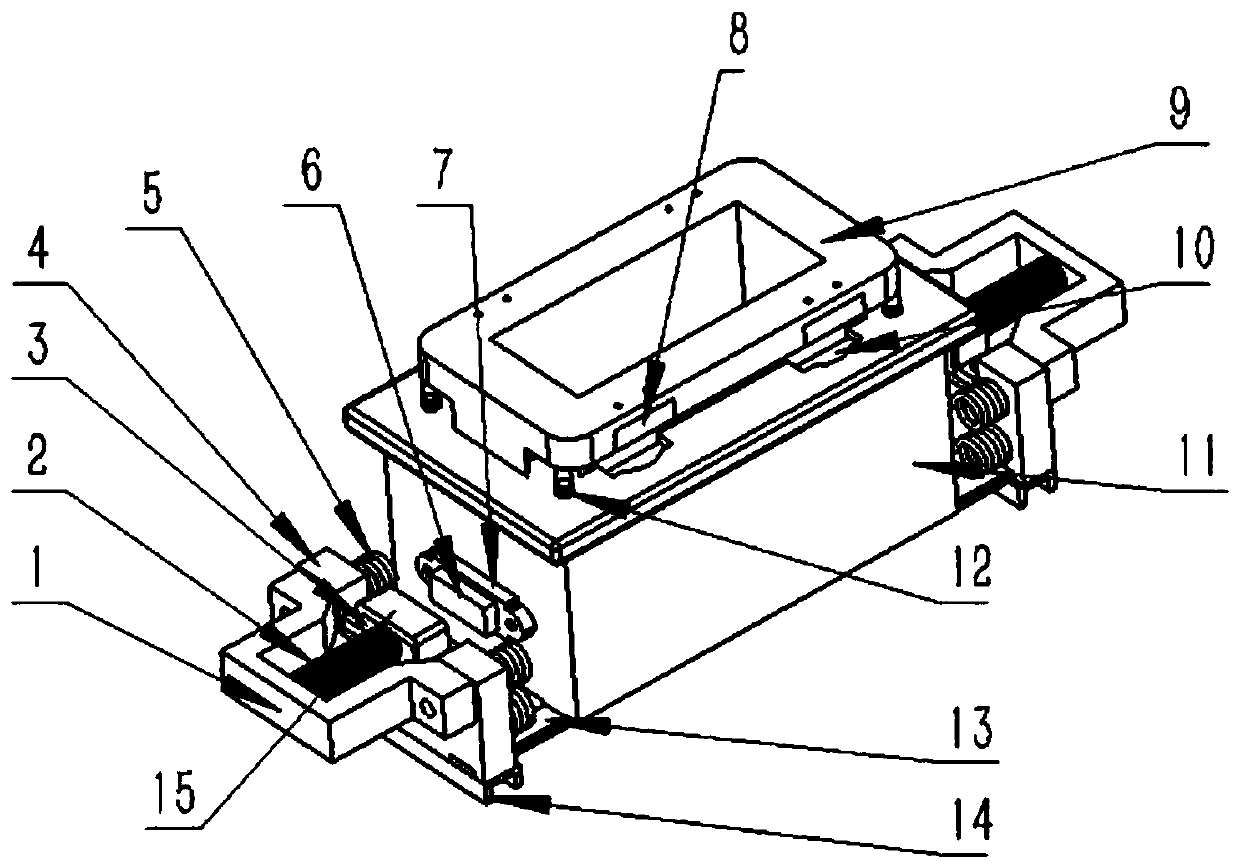

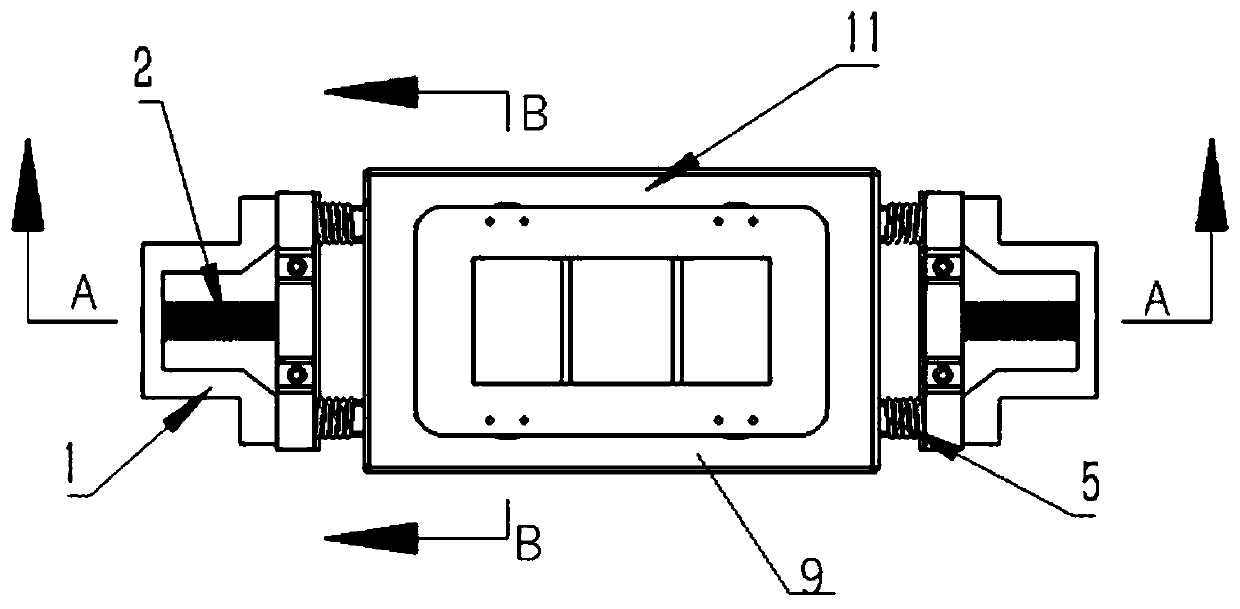

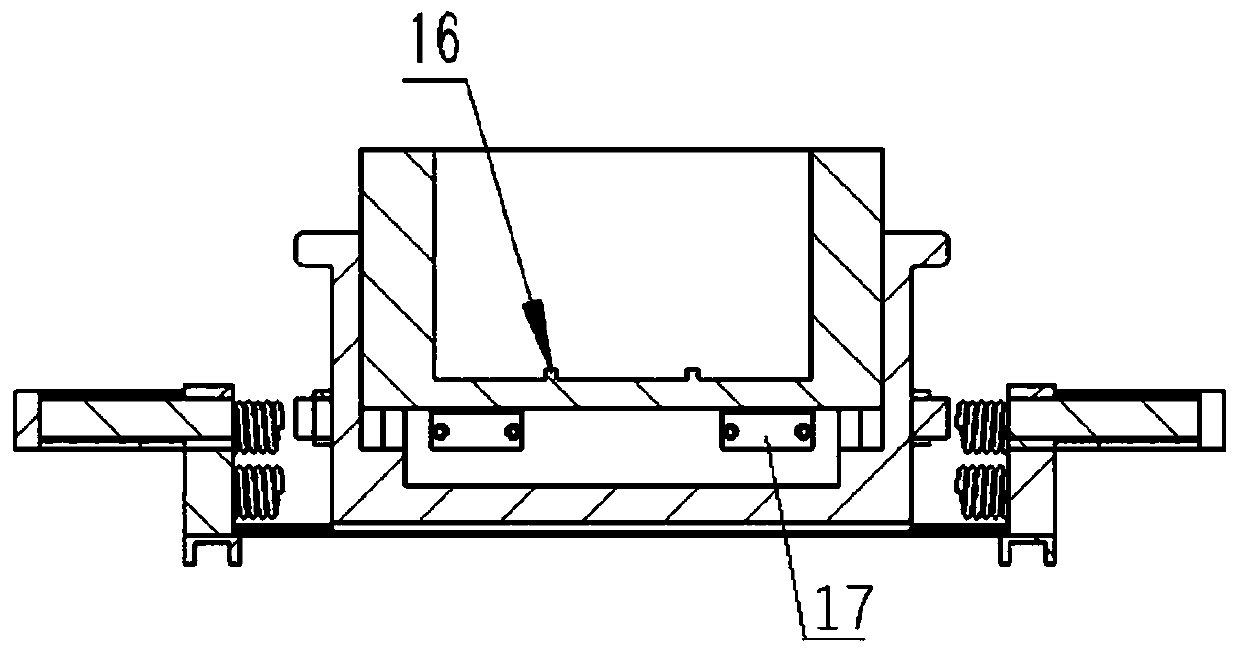

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0032] Such as Figure 1-Figure 4 As shown, an electromagnetic composite vibrating material layering device according to the present invention includes a box body 11, a material bin 9, a horizontal vibration mechanism and a vertical vibration mechanism; the material bin 9 is located in the box body 11; There are 2 groups of horizontal electromagnetic vibration mechanisms, which are respectively arranged at the two ends of the box body 11; each group of horizontal electromagnetic vibration mechanisms includes a horizontal electromagnet 2, a horizontal buffer spring 5 and a box body permanent magnet 6; the box body permanent magnet 6 is fixed on the box body. One end of body 11, the horizontal electromagnet 2 that cooperates with box body permanent magnet 6 is fixed on the fixing seat of box body 11 corresponding end outer sides at intervals, and ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com