Curtain box

A curtain box and curtain technology, which is applied in the field of curtain boxes, can solve the problems of complex installation process, multiple procedures, and long cycle, and achieve the effects of increasing overall rigidity, high degree of integration, and ensuring levelness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

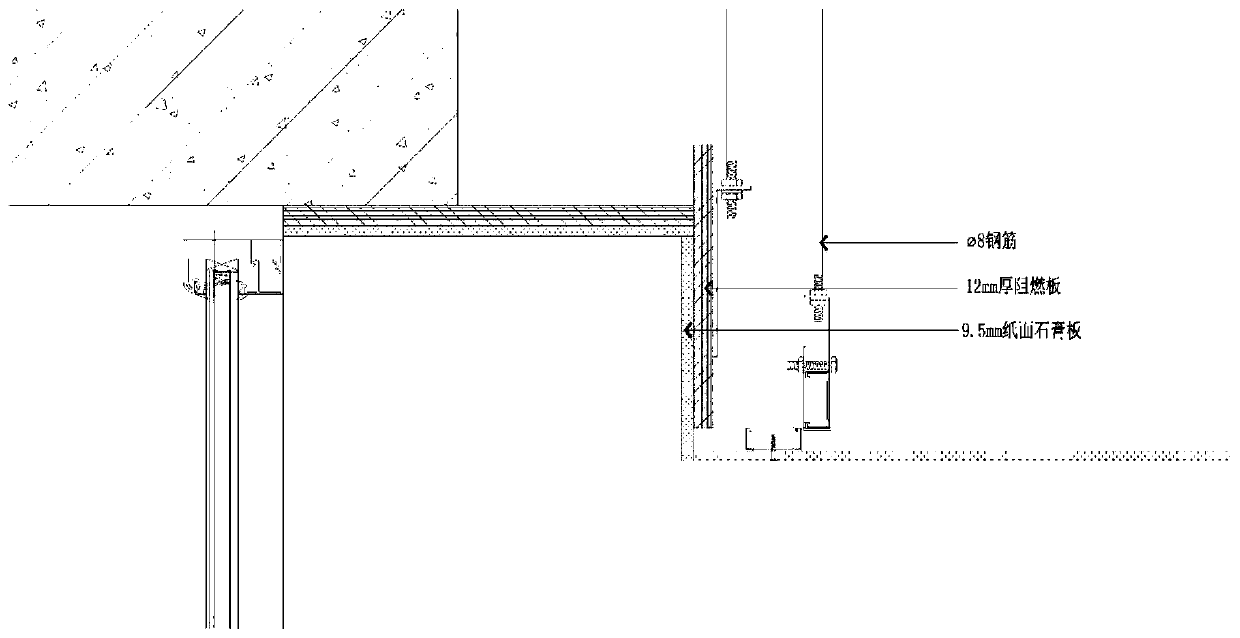

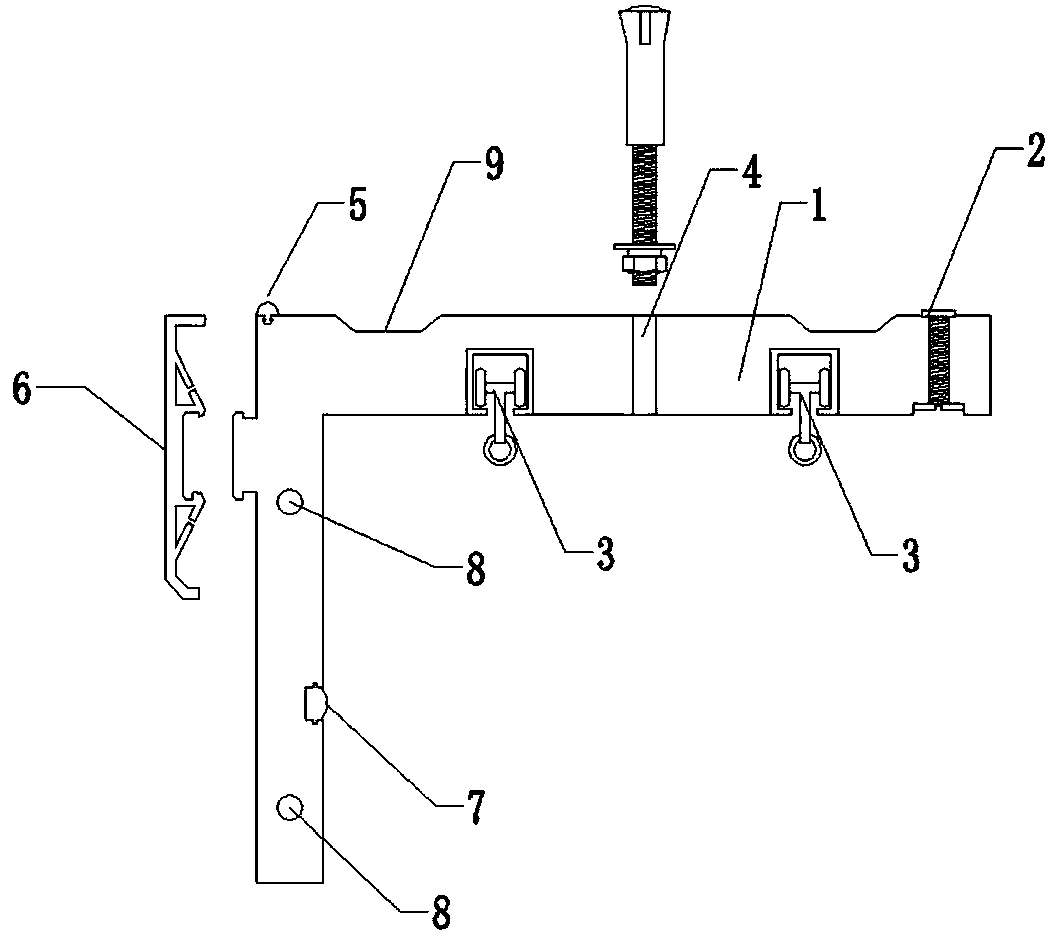

[0031] refer to figure 2 , Figure 4 to Figure 7, a curtain box, including a main body component 1 and a curtain rail 3, the improvement is that: the main body component 1 includes a horizontal part connected to the indoor suspended ceiling or ceiling 10, and a riser part connected to the end of the horizontal part , the curtain track 3 is arranged at the lower part of the horizontal part; the horizontal part is provided with a reserved installation hole 4 for the expansion bolt 13 to pass through, and the main body member 1 is fixed after the expansion bolt 13 passes through the reserved installation hole 4 It is connected with the indoor suspended ceiling or ceiling 10; the lower surface of the horizontal part is provided with a leveling counterbore, and the leveling counterbore penetrates the horizontal part vertically upwards, and the inner part of the leveling counterbore is screwed for leveling Bolt 2, the upper end surface of the leveling bolt 2 abuts against the indo...

Embodiment 2

[0043] On the basis of embodiment 1, with reference to figure 2 , Figure 4 to Figure 7 , the upper surface of the horizontal portion is provided with a downwardly recessed groove 9 .

[0044] In this embodiment, by setting the groove 9 on the horizontal part of the main body component 1, the overall rigidity of the main body component 1 can be increased, so that the main body component 1 is not easy to be bent and deformed, so as to avoid bending and deformation of the curtain box after long-term use. deformation etc.

[0045] Further, the number of the grooves 9 is one, two or three; preferably, the number of the grooves 9 is two, and the two grooves 9 are symmetrically arranged on both sides of the reserved installation hole 4;

[0046] Furthermore, the cross-sectional shape of the groove 9 is arc-shaped, rectangular or trapezoidal.

Embodiment 3

[0048] On the basis of Embodiment 1 or 2, a buffer pad is provided on the end surface of the leveling bolt 2 abutting against the indoor suspended ceiling or ceiling 10 .

[0049] In this embodiment, the flexible contact between the end surface of the leveling bolt 2 and the indoor ceiling or ceiling 10 is ensured by setting the buffer pad, thereby reducing the hard contact damage caused by the leveling bolt 2 to the surface of the indoor ceiling or ceiling 10 during the leveling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com