Polyurethane foam system

A polyurethane foam, foam technology, applied in the field of low-emission polyurethane foam systems, can solve the problems of reducing emissions, foam products not showing processing characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

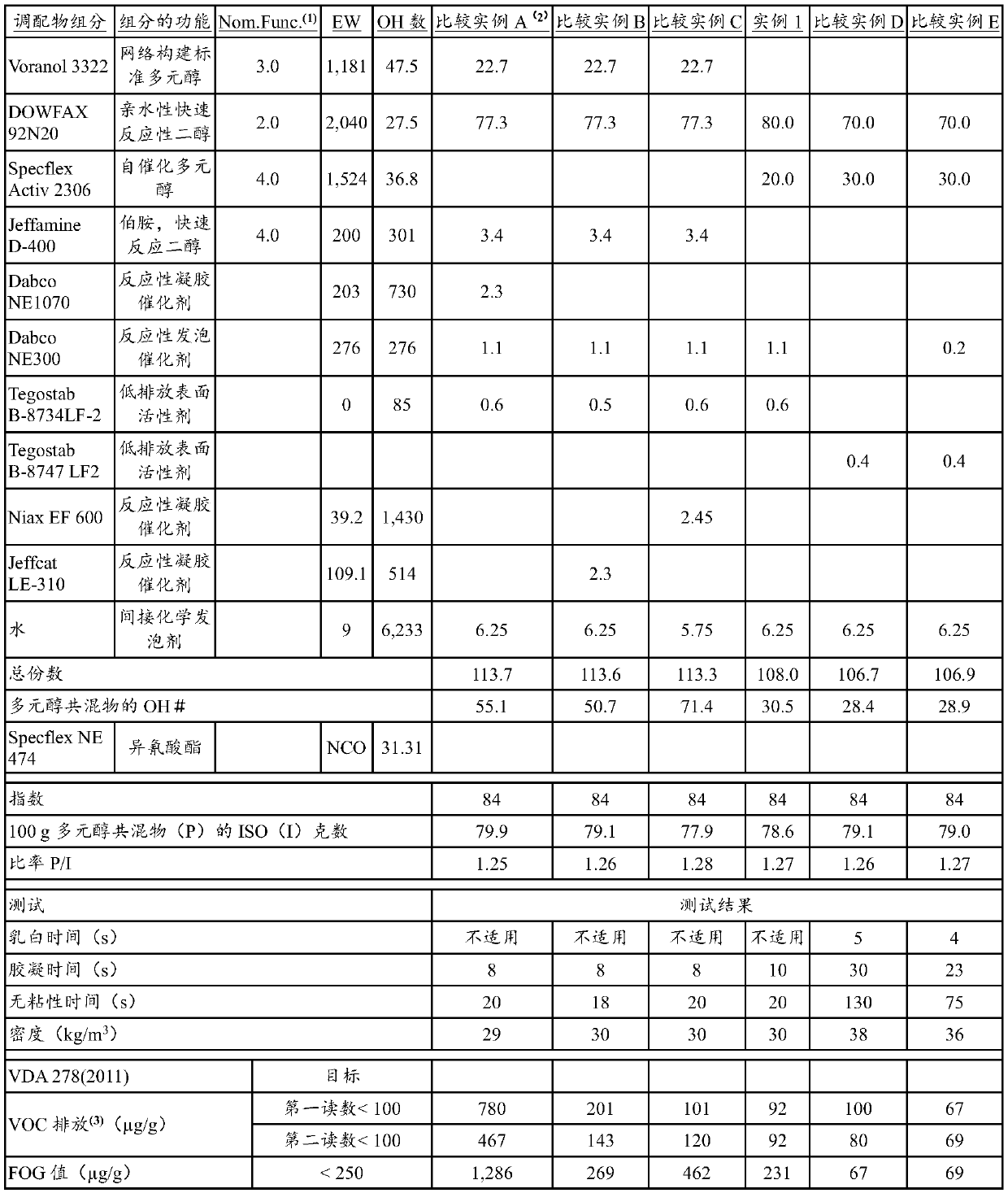

[0088] The following examples are presented to further illustrate the invention, but are not to be construed as limiting the scope of the claims. All parts and percentages are by weight unless otherwise indicated.

[0089] Various terms and designations used in the following examples are explained below.

[0090] DOWFAX 92N20 is a mixed oxide (PO / EO) polyether polyol with a nominal functionality of 2, a hydroxyl number between 26 and 29, and an EO content of 20 wt%. DOWFAX 92N20 is commercially available from The Dow Chemical Company.

[0091] VORANOL 3322 is a mixed oxide (PO / EO) polyether polyol having a nominal functionality of 3 and having a hydroxyl number between 46 and 50; and is commercially available from The Dow Chemical Company.

[0092] SPECFLEX ACTIV 2306 is an amine initiated autocatalytic polyether polyol having a nominal functionality of about 4 and a hydroxyl number between 31.0 and 40.0; and is commercially available from The Dow Chemical Company.

[0093]...

example 1 and comparative example A-E

[0104] The examples described in Table I contain formulated polyol blends reacted with MDI. MDI has an isocyanate content of about 31% by weight. The polyol blend (B side material) and polymeric MDI (A side material) were mixed in a polyurethane dispenser. This dispensing machine is a standard machine available on the market, eg from equipment suppliers such as Henneke, Krauss Maffei and Cannon. In the examples prepared as described in Table 1, Cannon AP10 dispensing equipment with a LN5 impact mix head was used; and the formulations were subjected to the following processing conditions:

[0105] The dispenser is capable of mixing a given foam forming system at a given ratio of isocyanate to polyol. The ratio is controlled by the size of the pump / motor. The dispensing temperature of the material is typically in the range of 20°C to 60°C. In the example, the temperature of the polymer T(poly) is 40°C; and the temperature of the isocyanate T(iso) is 40°C.

[0106] At a mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com