Correction-and-shaping-combined automatic pre-injection-molding integration device for power source lines

A technology that integrates devices and power lines, applied in circuits, electrical components, circuit/collector parts, etc., can solve the problems of correcting to the specified state, low production efficiency, difficult power line pin insertion, etc., to facilitate injection molding, improve Correction quality, location-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

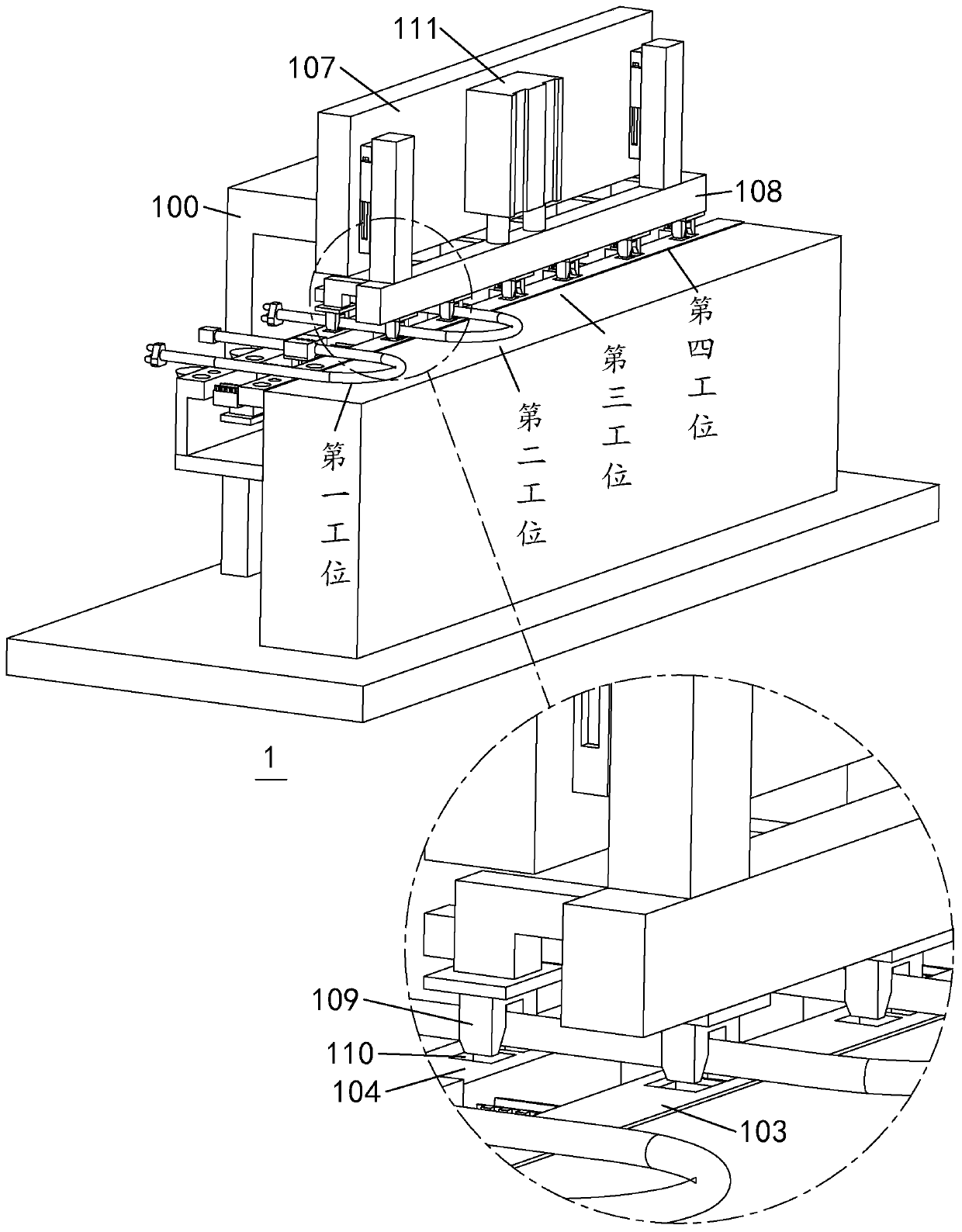

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0030] The following reference Figure 1 to Figure 9 The present invention will be described.

[0031]An automatic integration device for power cords before injection molding that combines rectification and shaping, including an equipment bracket 100, a power cord placement platform 101, a clamping mechanism and a driving mechanism. The power cord placement platform 101 is set on the front side of the equipment bracket 100 and its lower end is fixed On the ground, the rear side of the power cord placement platform 101 is provided with a support platform 103 and a support platform 2 104, and the support platform 103 and the support platform 2 104 are elongated and the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com