Oil storage tank oil gauging matching device convenient facilitating opening and closing oil gauging hole

A technology for oil storage tanks and oil measuring holes, which is applied in the field of oil measuring accessories for oil storage tanks, and can solve the problems of inconvenient oil measuring devices being placed in the oil measuring holes, reducing the use experience of oil storage tank products, and spending sampling time, etc. To achieve the effect of convenient sampling and detection, solving winding and convenient sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

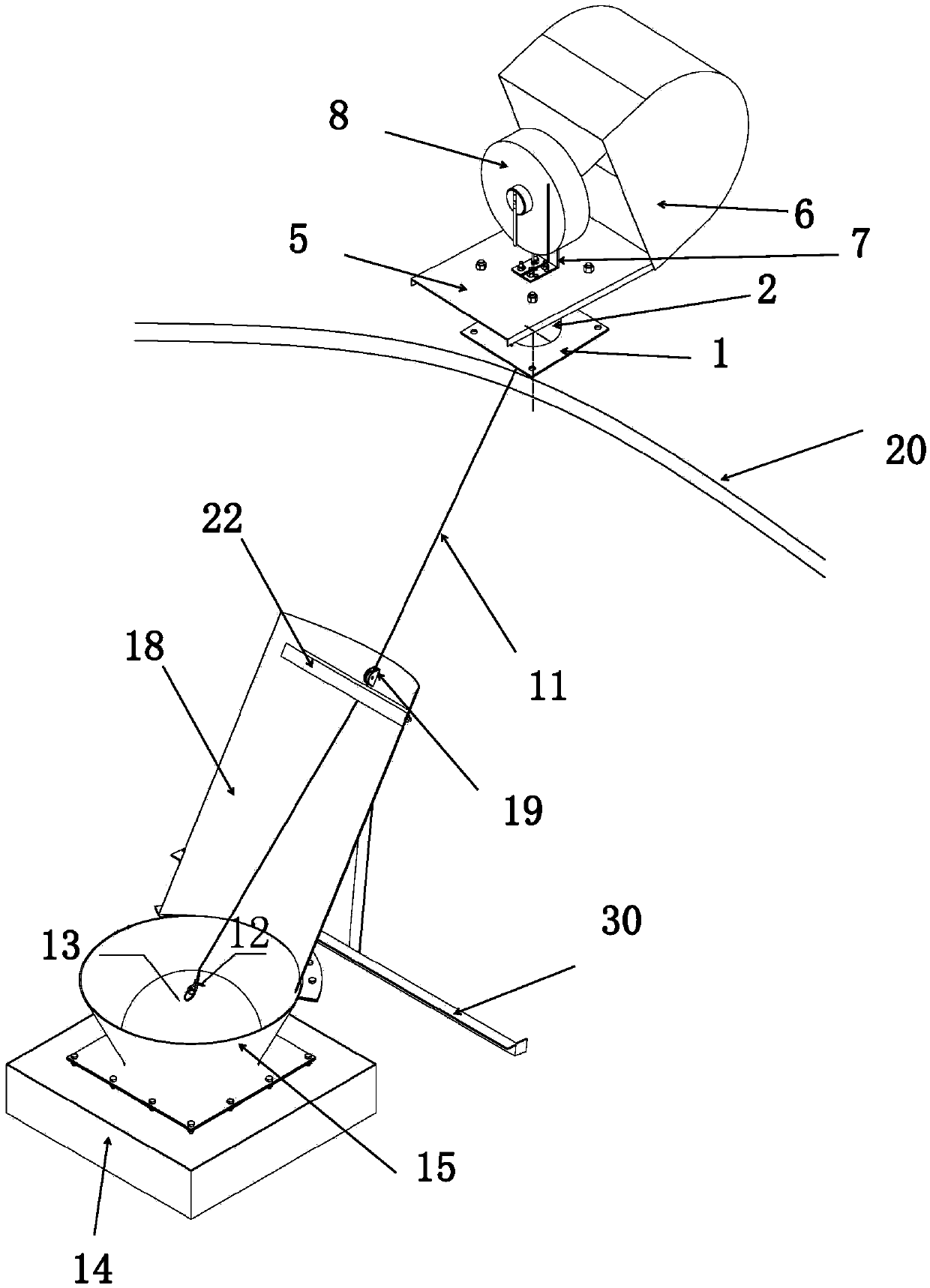

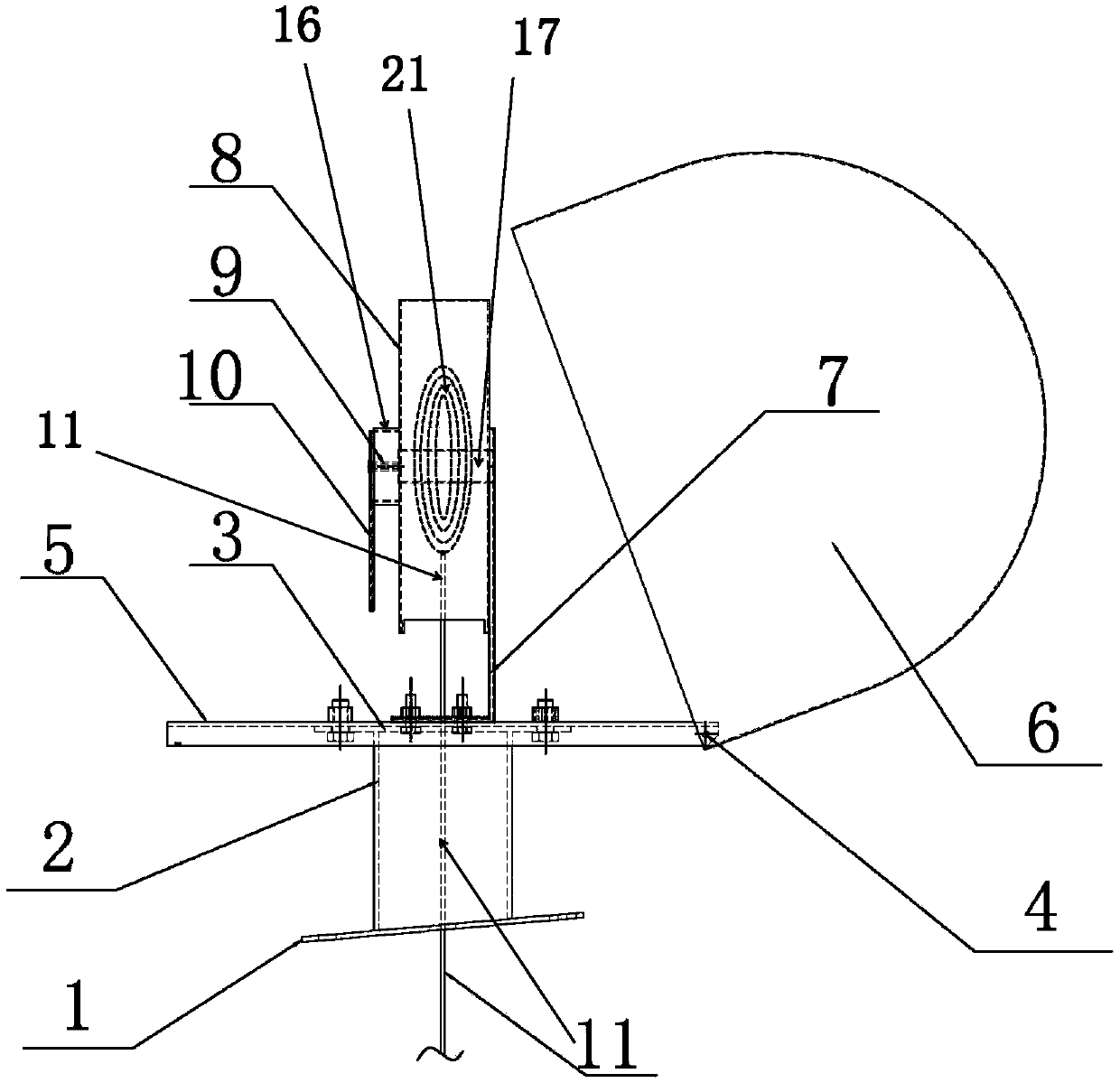

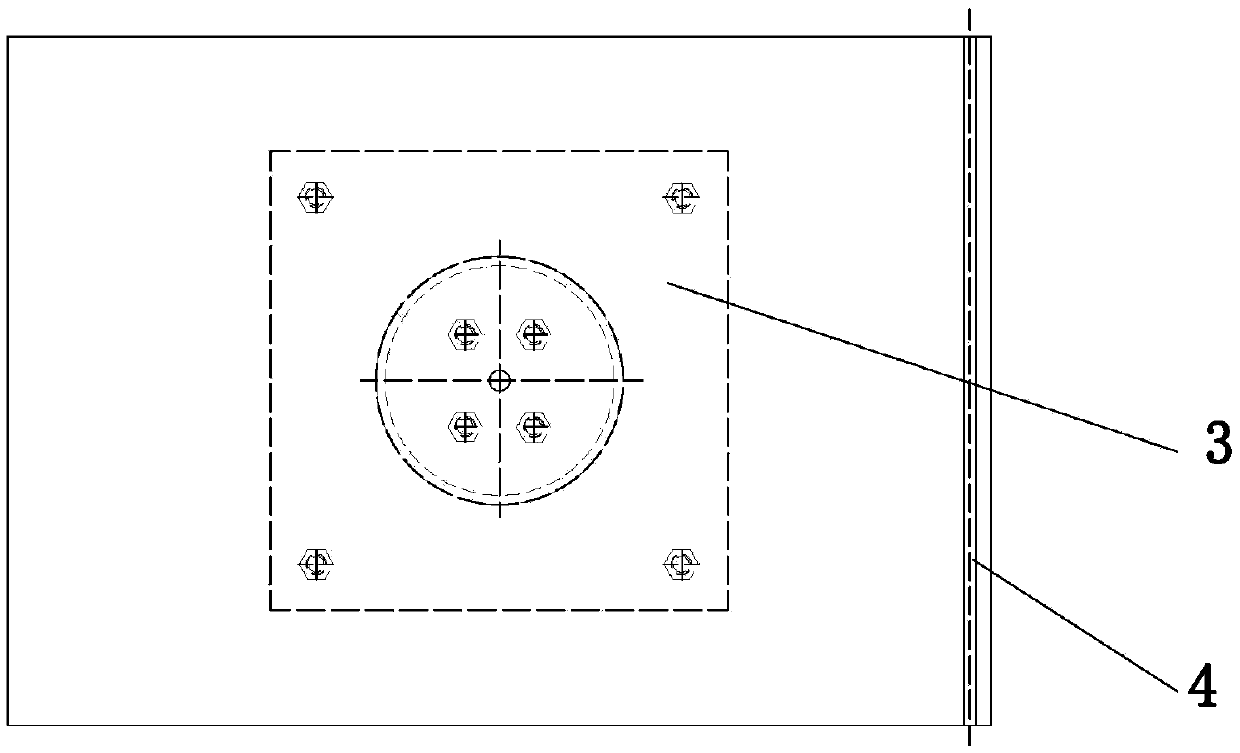

[0048] see Figure 1 to Figure 5 , the present invention provides an oil storage tank oil measurement supporting device which is convenient to open and close the oil measurement hole, which is an important supporting structure of the oil storage tank. Set the type of liquid medium (such as gasoline or diesel, etc.);

[0049] A circular inner floating roof 30 is placed in the oil storage tank, and an oil measuring hole is opened on the inner floating roof 30, and the inner floating roof is in contact with the liquid surface (specifically: immersed in the liquid surface for a certain distance , such as 2 to 3 cm, to avoid the formation of oil and gas spaces);

[0050] The supporting device for measuring oil comprises an oil measuring hole ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com