Cantilever type bearing test bench

A bearing test, cantilever technology, applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve the problem of inconvenient factory inspection of sliding bearings, achieve convenient testing, improve versatility, and enrich testing effect of means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

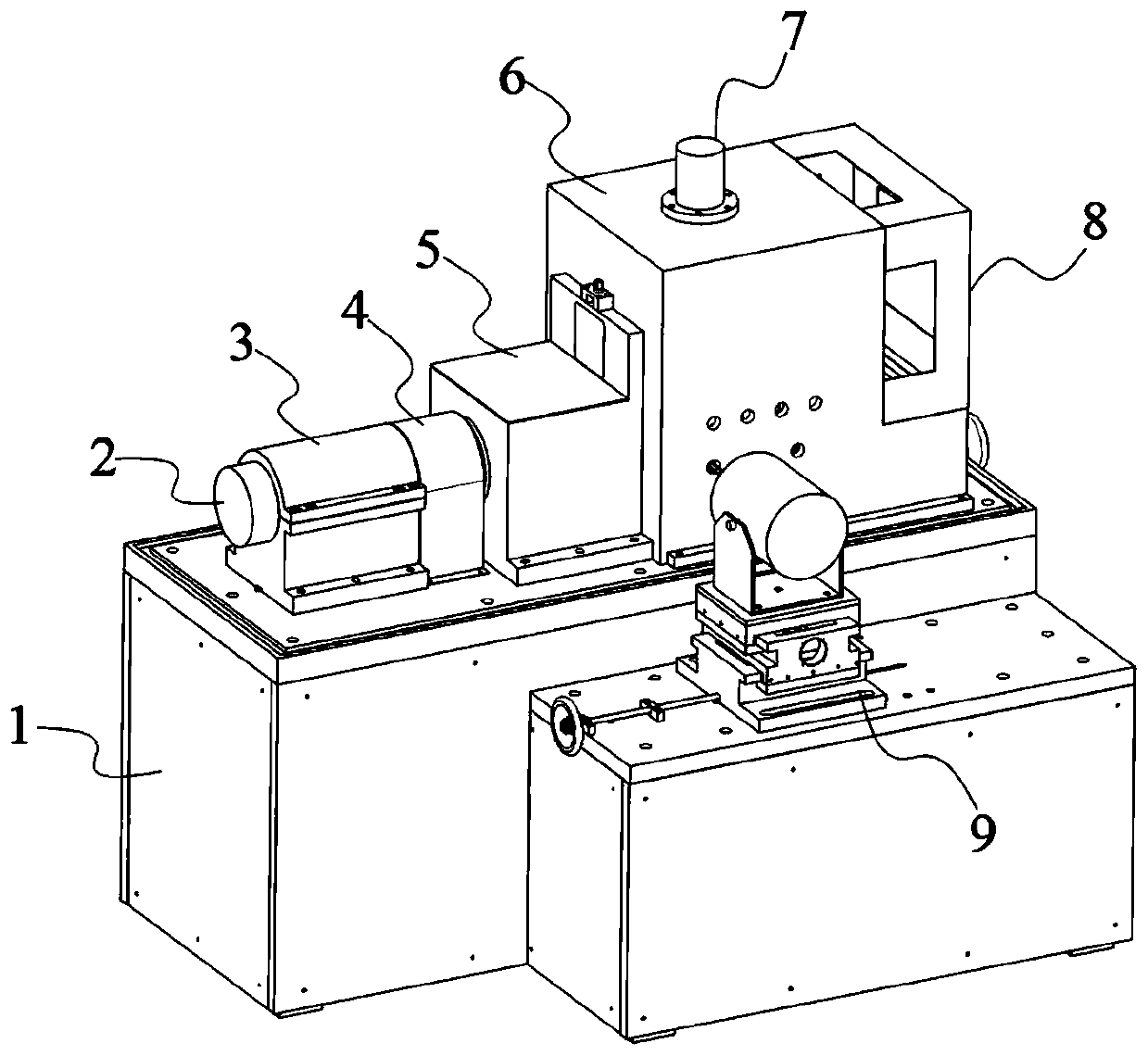

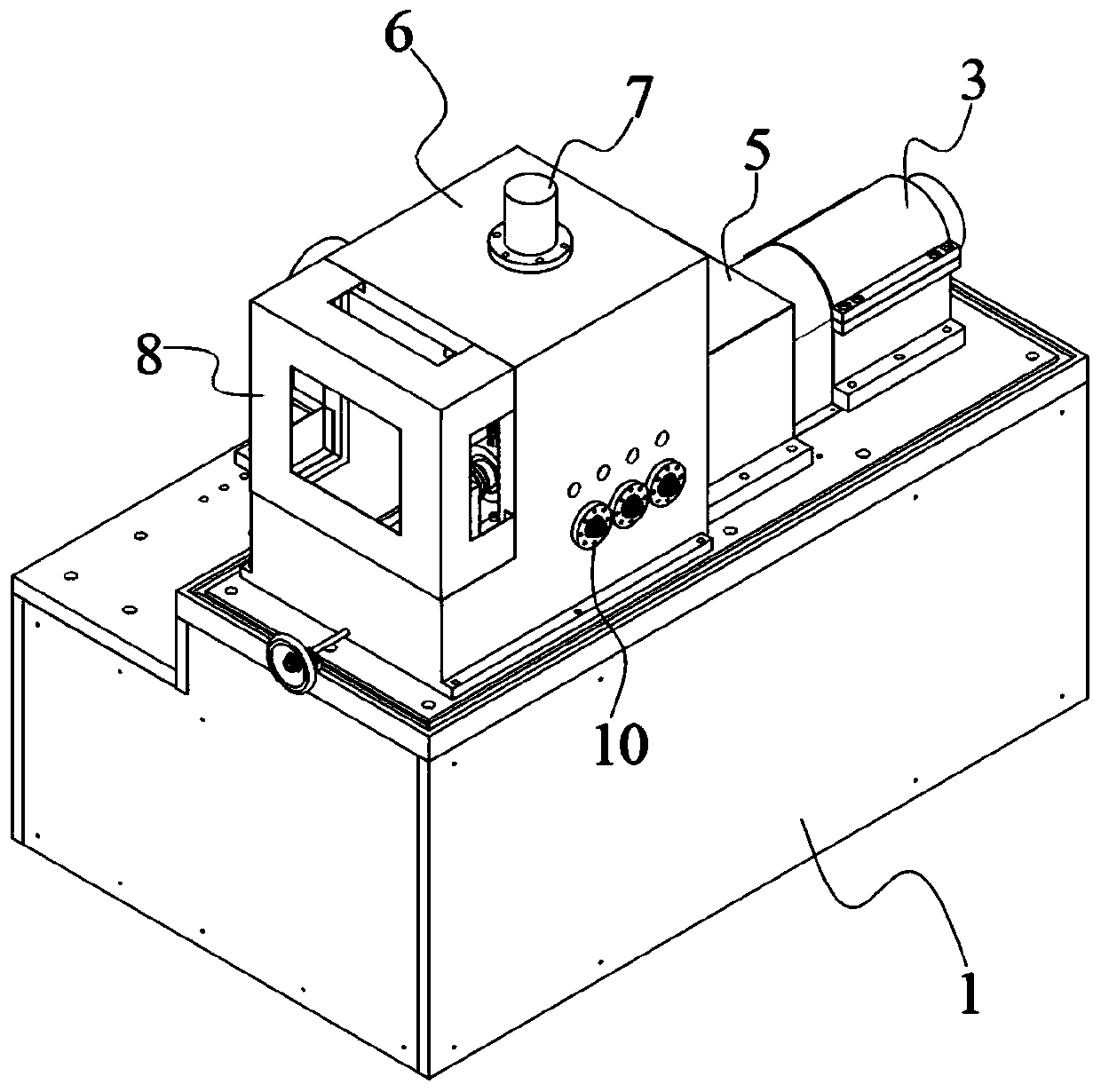

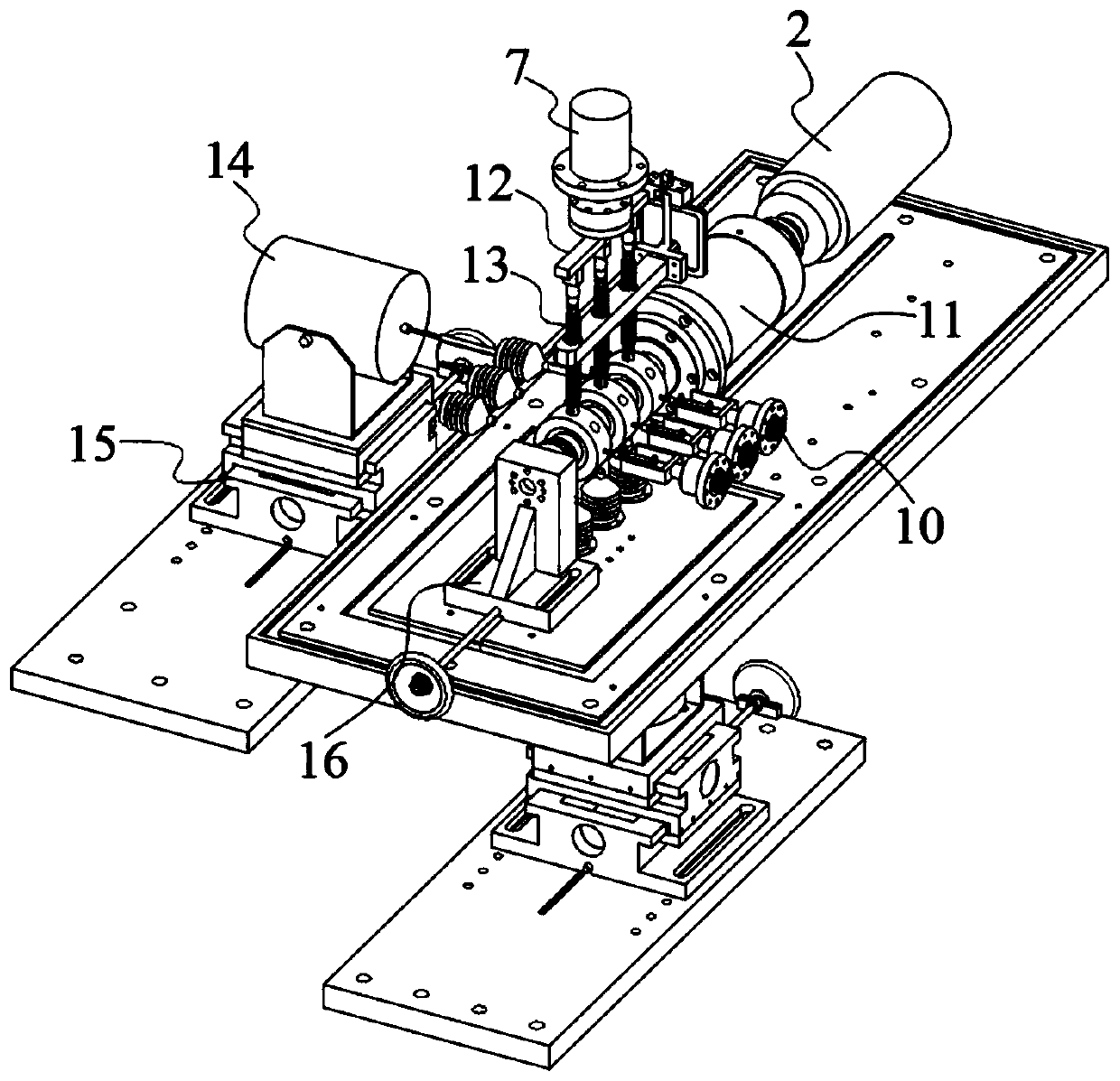

[0029] like Figure 1 to Figure 10 Shown is a cantilever bearing test bench of a preferred embodiment of the embodiment of the present invention. The cantilever bearing test bench includes a shock-absorbing base 1 and a motor drive device 2 installed on the shock-absorbing base 1, a transition shaft assembly 11, an auxiliary support 16, and a loading device. One end of the transition shaft assembly 11 is connected to the motor drive device 2, the other end is rotatably assembled with the auxiliary support 16; the transition shaft assembly 11 has a mounting section 27 for the test bearing 25 to be set and fixed; the loading device includes a static loading mechanism and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com