Method for determining reference values of sensor, and controller

A reference value, sensor technology, used in transmission control, elements with teeth, belts/chains/gears, etc., can solve the problem of not having transmission accuracy, affecting position determination, not considering service life drift sensing system and temperature related issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

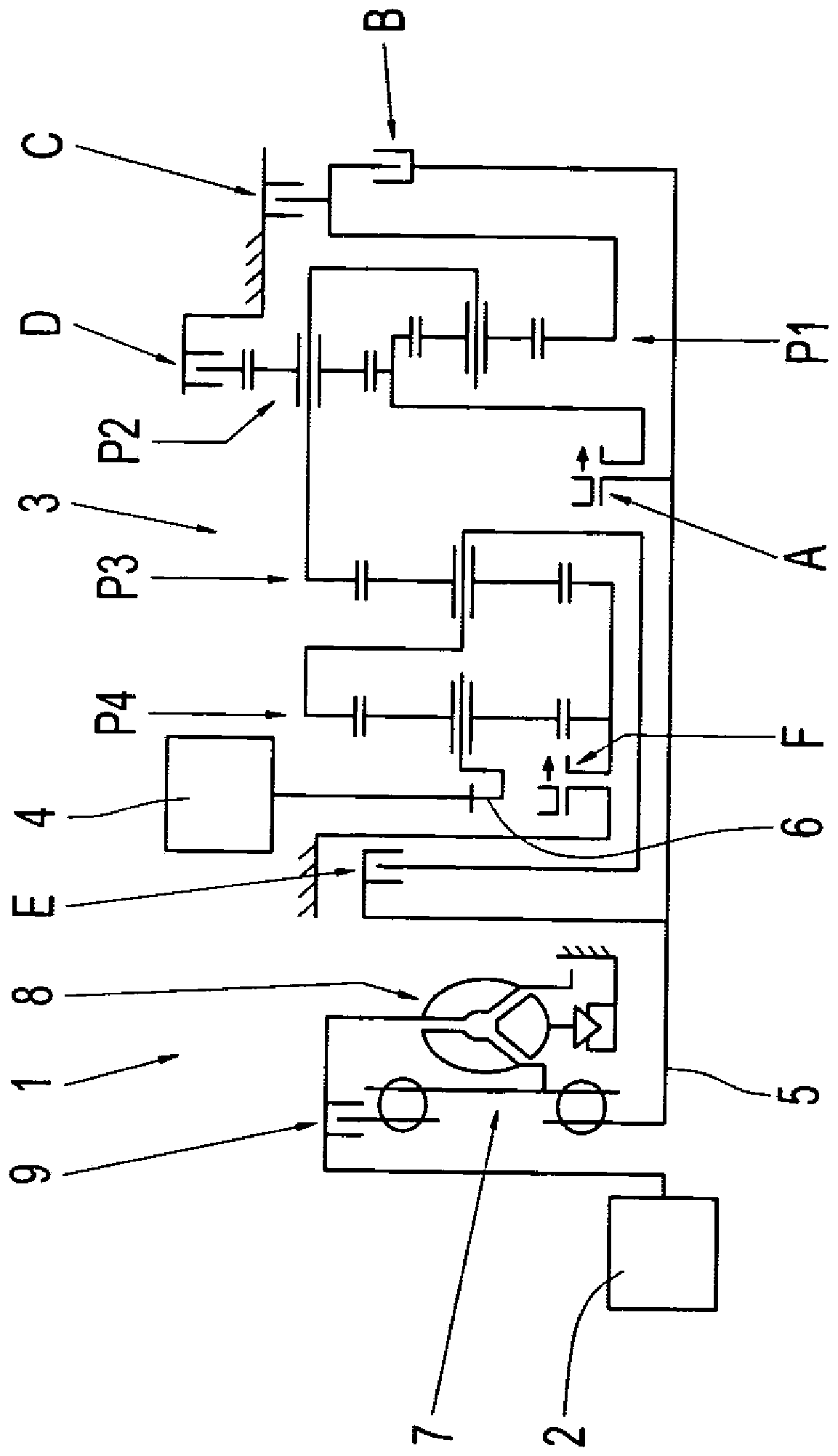

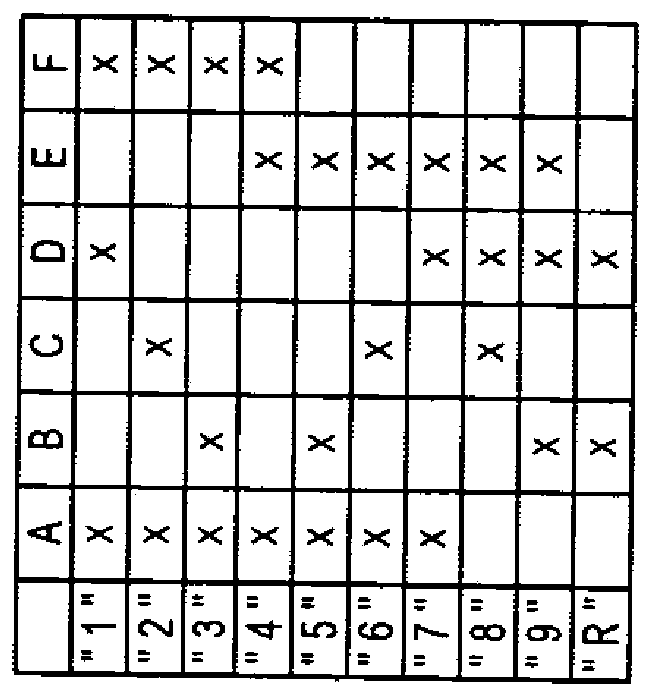

[0062] figure 1 A schematic diagram of a vehicle drive train 1 including a drive machine 2 , a transmission 3 and a driven output 4 is shown. Drive machine 2 is presently designed as an internal combustion engine. The transmission 3 is an automatic transmission in which a plurality of gear stages "1" to "9" for forward travel and at least one gear stage "R" for reverse travel are possible. Depending on the configuration of the drive train 1 of the vehicle, the output output 4 includes one, two or more drivable axles, which can be acted upon by the torque of the drive machine 2 via the transmission 3 . The hydraulically actuatable shift elements A to F are actuated during a gear ratio change in the transmission 3 , ie during an upshift or a downshift in the transmission 3 . In this case, the gear ratio change should be carried out essentially without interruption of the tractive force with a high level of driving comfort and with the desired performance. The term "performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com