Mine track type inspection climbing robot

A robot and track-type technology, applied in the field of robots, can solve problems such as the reduction of the friction coefficient of the walking track, the slippage of the inspection robot, and the impact on normal inspections, so as to reduce frictional resistance and energy consumption, increase cruising range, and improve safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

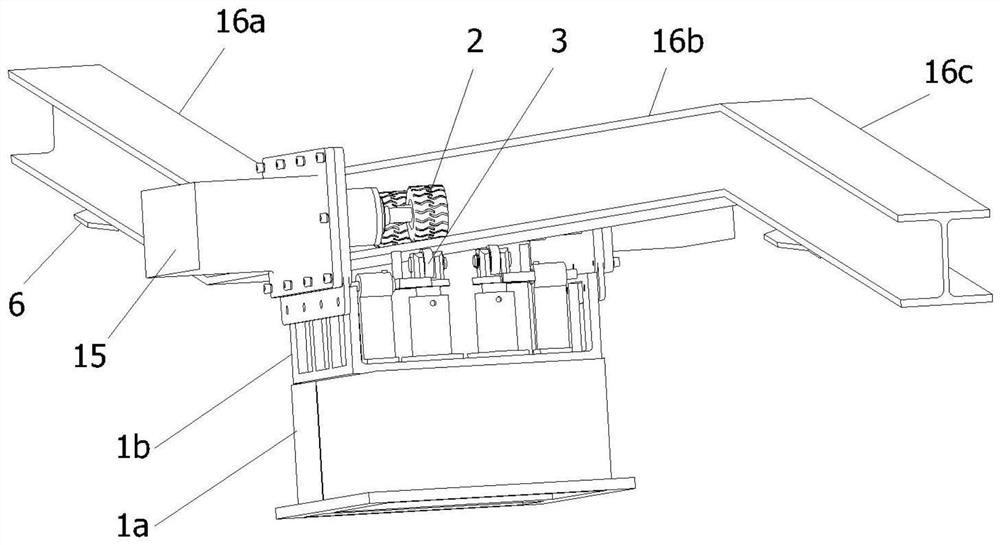

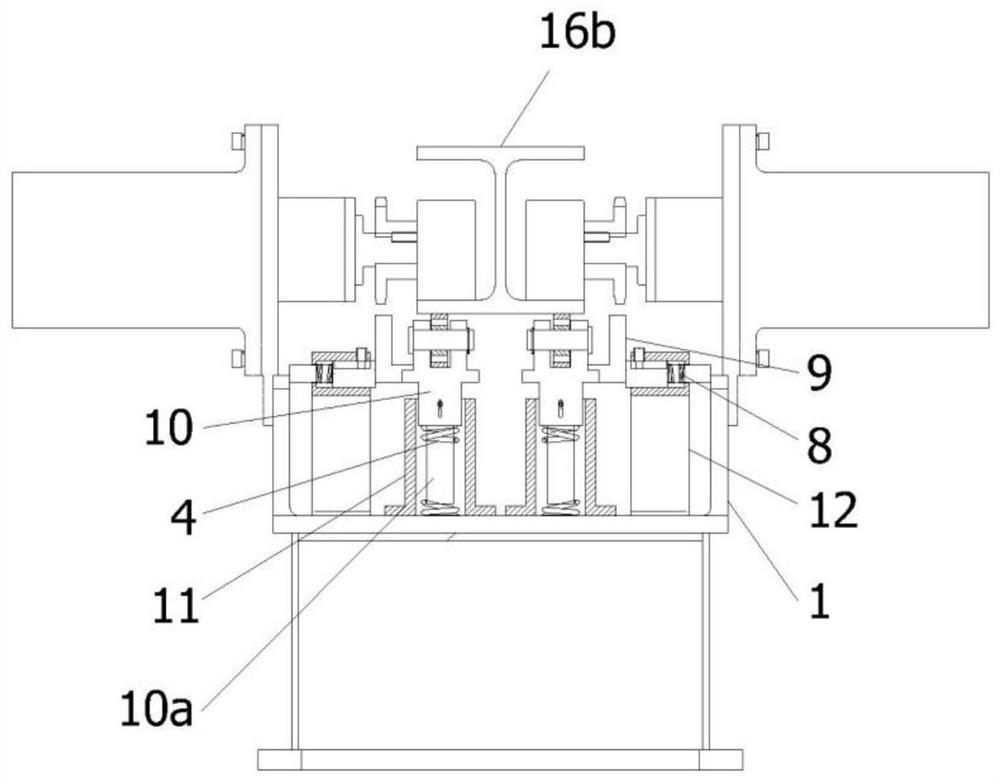

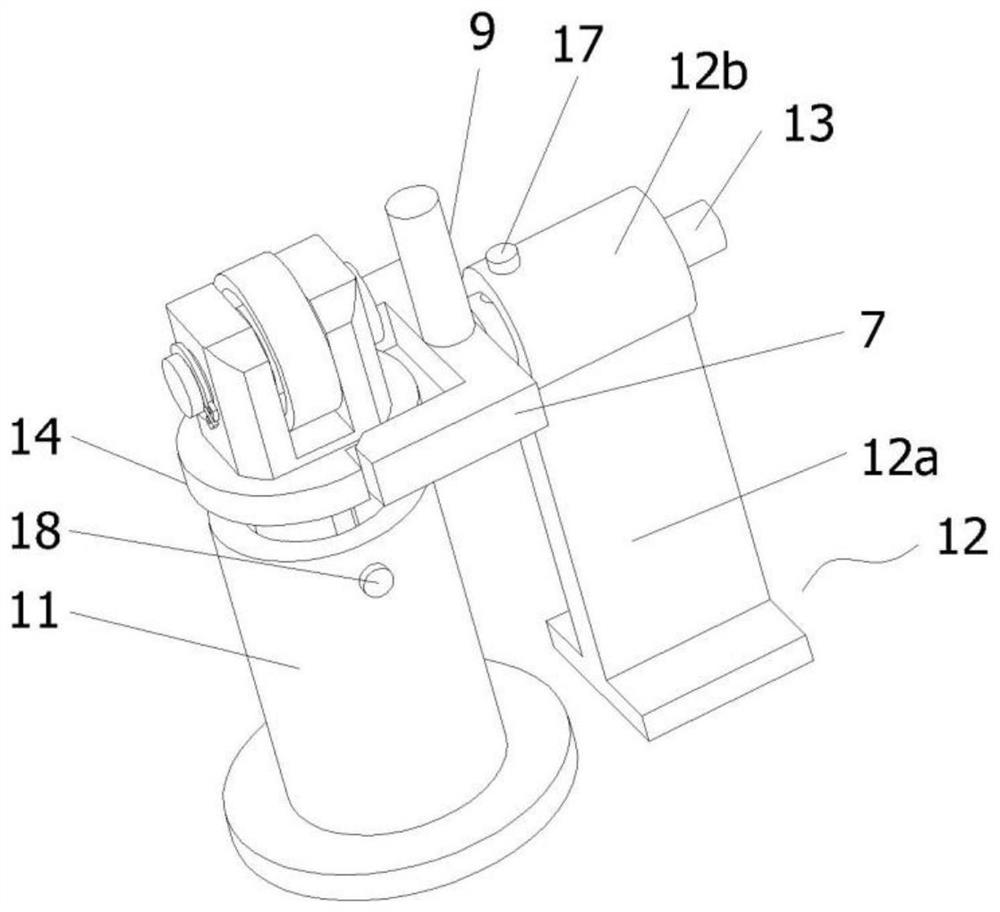

[0022] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic cross-sectional structure diagram of the present invention; image 3 A diagram of the local composition; Figure 4 It is a schematic diagram of the structure of the horizontal protrusion and the vertical protrusion;

[0023] As shown in the accompanying drawings, this embodiment provides a mining track-type inspection and climbing robot, including a frame 1, which is installed on the frame and used to roll along the track wing to drive the frame to walk along the track. Wheel 2, the driving device that drives the traveling wheel to rotate, the pressing wheel 3 that is installed on the frame for pressing on the bottom of the track wing plate, and the adjusting device for adjusting the pressing wheel. When going downhill, make the pinch wheel close to the track and press against the bottom of the rail wing, and keep the pinch wheel away from the track when the robot walk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com