Miniature auditory meatus type hearing aid

A hearing aid, ear canal type technology, applied in the field of miniature ear canal type hearing aids, can solve the problems of inability to wear deeper, poor comfort and concealment, high labor cost, etc., to improve wearing comfort, improve wearing comfort, and avoid glue pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

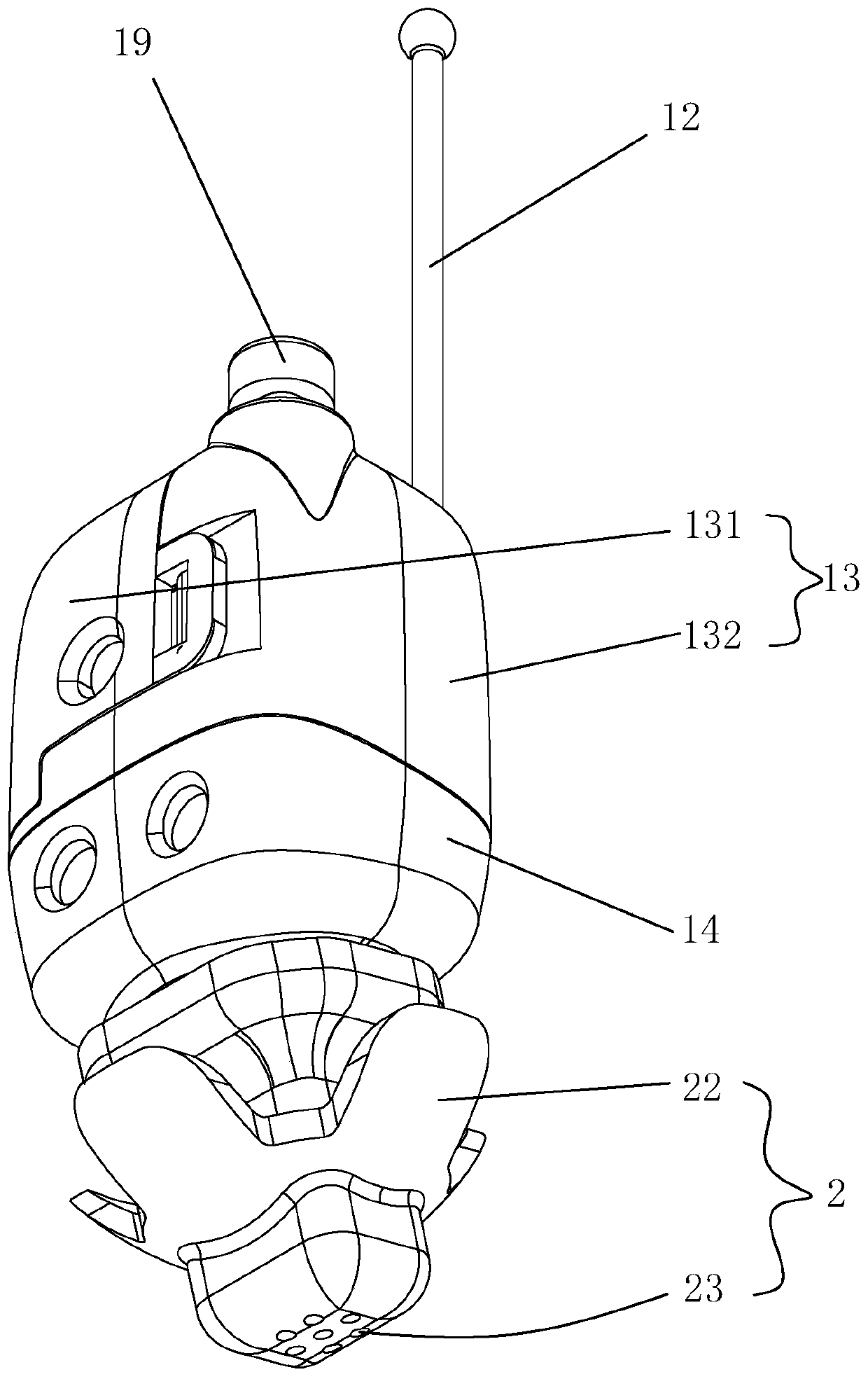

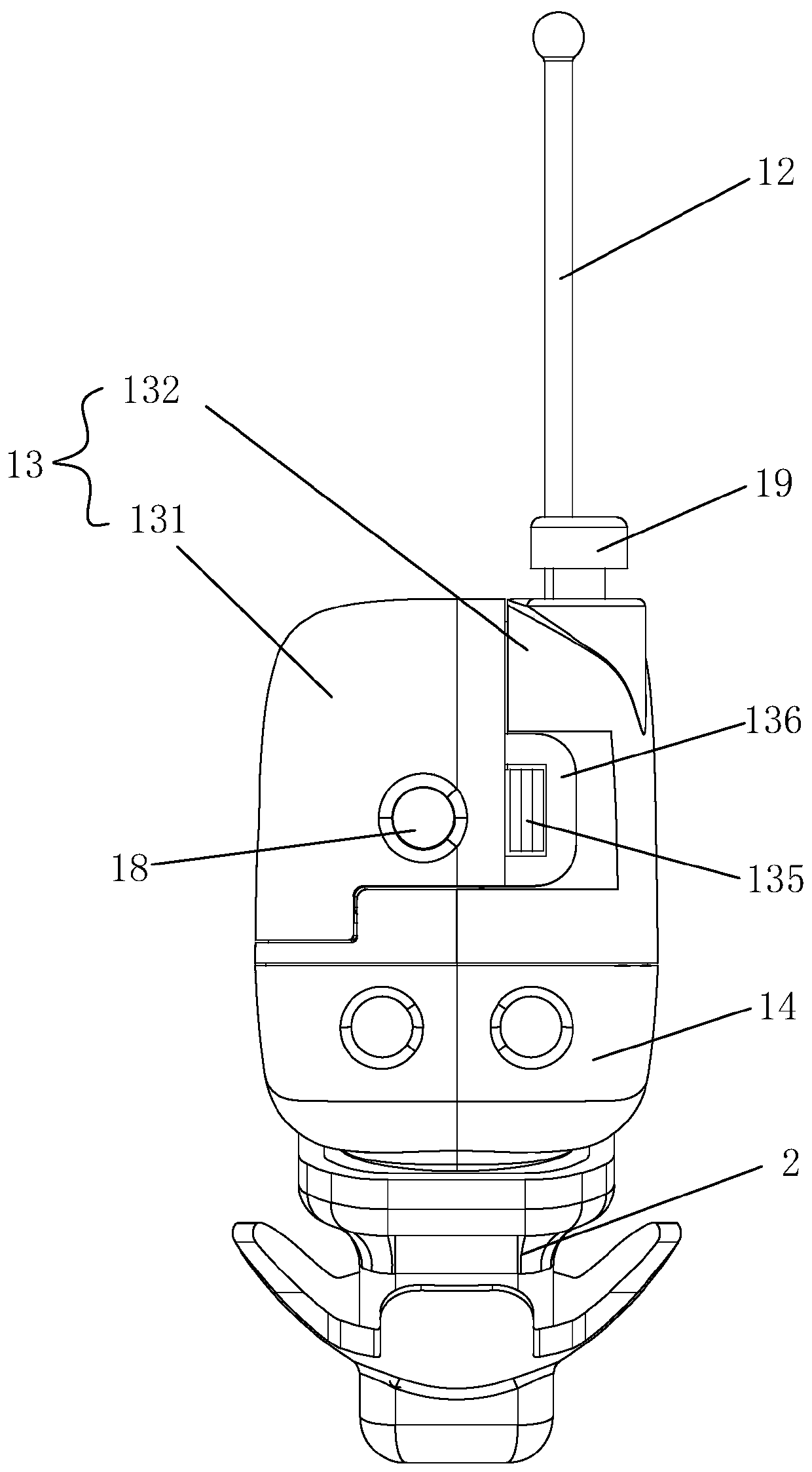

[0044] Such as Figure 1 to Figure 10 As shown, in the miniature ear canal hearing aid disclosed by the present invention, other electronic components except the receiver 3 are wrapped inside the housing 1, the front end of the housing 1 is sealed and fixed at the rear end of the receiver 3, and the sound outlet 31 of the receiver 3 Exposed outside the casing 1 , the eardrum head 2 is wrapped on the receiver 3 , and the eardrum head 2 is detachably fixed on the front end of the casing 1 , and the sound outlet 31 of the receiver 3 is located inside the eardrum head 2 . The shell 1 of the present invention can be made of hard plastic material, and the eardrum head 2 is made of soft rubber material, thereby forming a miniature ear canal hearing aid combined with a soft and hard shell.

[0045] The key point of the present invention is to expose most of the receiver 3 outside the housing 1, and other electronic components (such as chips 4 and microphones 5, etc.) are still protected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com