Doorsill beam assembly

A technology of sill beams and components, applied in the field of sill beam components, can solve problems such as poor energy absorption effect, affecting the safety and reliability of the whole vehicle, and achieve the effects of increasing energy absorption, improving collision safety, and ensuring ride safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

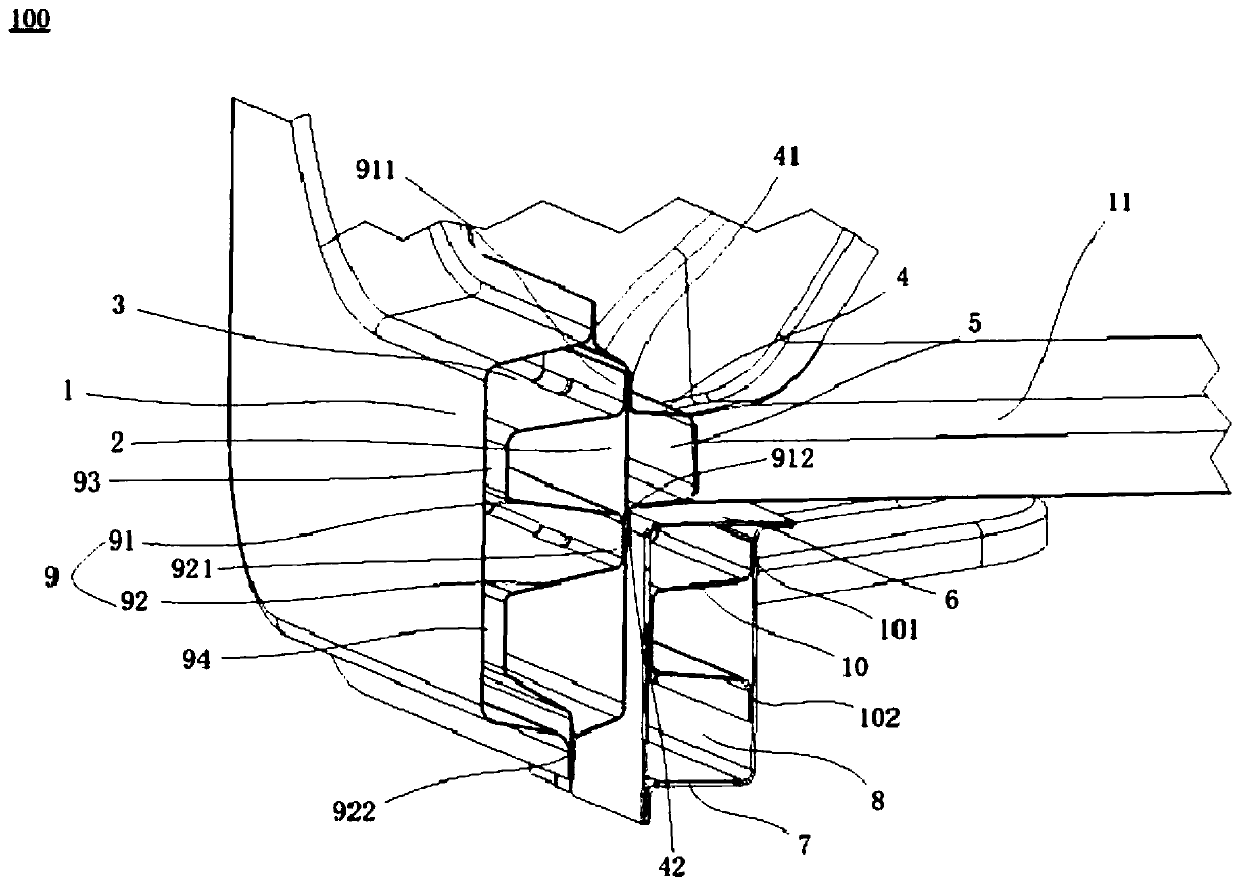

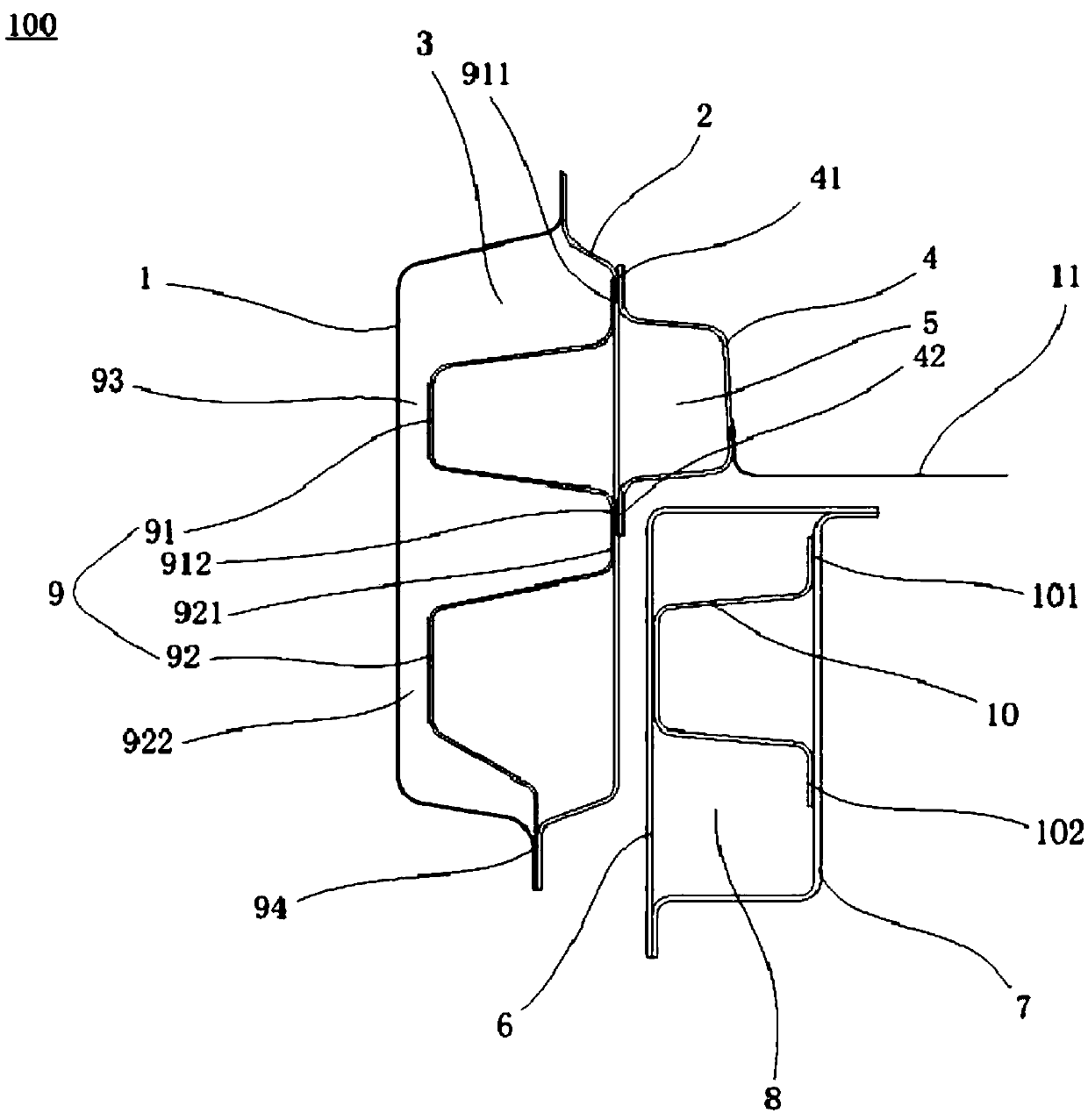

[0023] Refer below Figure 1-Figure 2 A rocker beam assembly 100 according to an embodiment of the present invention is described.

[0024] The rocker assembly 100 according to the embodiment of the present invention may include: a side wall outer panel 1 , a side rocker beam 2 , a front floor rocker beam 4 , a rocker side sill outer panel 6 and a rocker side sill inner panel 7 .

[0025] Such as figure 1 with figure 2 As shown, the side wall outer panel 1 is fixed to the side wall door sill beam 2 to define a first buffer cavity 3 between the side wall outer panel 1 and the side wall door sill beam 2 . Specifically, the side wall sill beam 2 is arranged on the outside of the side wall outer panel 1, and the side wall outer panel 1 and the side wall door sill beam 2 are welded and fixed to form a first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com