Multidimensional vibration sorting system with intelligent frequency modulation

A multi-dimensional and intelligent technology, applied in the processing field of accessories, can solve the problems of damage and wear of precision accessories, and achieve the effect of reducing the number of collisions, reducing the crowding, and reducing the collision intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

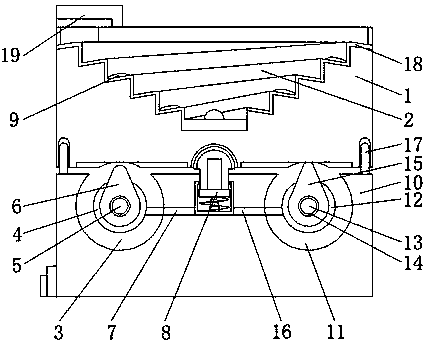

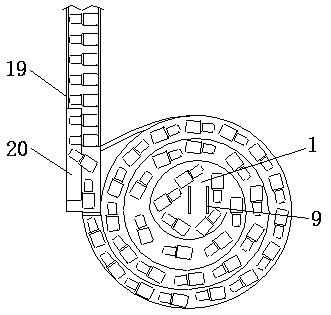

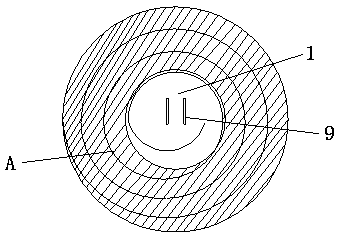

[0024] An intelligent frequency modulation multi-dimensional vibration sorting system includes a vibrating plate, a chassis, a vibrating mechanism and a gravity sensing device; the gravity sensing device acts on the vibrating plate, and recognizes the gravity change on the designated position A on the vibrating plate; the vibrating mechanism has 2 or more vibration frequencies, and / or have 2 or more vibration amplitudes, and / or have 2 or more vibration modes; the vibration mechanism drives the vibrating plate, and when the gravity sensing device recognizes the specified position on the vibrating plate When the gravity on A changes as specified, the vibration frequency and / or vibration amplitude and / or vibration mode of the vibration mechanism are switched. The specified position A on the vibrating plate is the outer contour line, and the interval formed by the boundary line formed by shrinking the outer contour line by 23.5%-35% is as follows: image 3 A region in . The specif...

Embodiment 2

[0032] Vibration mechanism and heavy induction device as described in embodiment 1:

[0033] When the accessories in the vibration plate 1 above the right cam get together and the pressure reaches the maximum pressure value, the vibration device drives the first drive motor 12 on the right to drive the large cam 15 to rotate, increasing the vibration frequency and amplitude; when the vibration above the left cam When the accessories in the tray are piled up and the pressure reaches the maximum pressure value, the vibrating device drives the second drive motor on the left to drive the large cam to rotate, increasing the vibration frequency and amplitude, so that the accessories are separated or dropped.

[0034] When the gravity sensing device feels that the pressure on the vibrating plate is less than the minimum value, the vibrating mechanism will make the two driving motors drive the large cam to rotate at the same time, increasing the overall vibration frequency and amplitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com