A cooling water spray component for laser cutting, a spray device and a laser cutting machine

A laser cutting machine and laser cutting technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of hot nozzle of the cutting head, cooling of the plate that cannot be cut, and cooling of the nozzle of the laser cutting head. , to achieve the effect of improving the effect, preventing excessive heating, and increasing the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

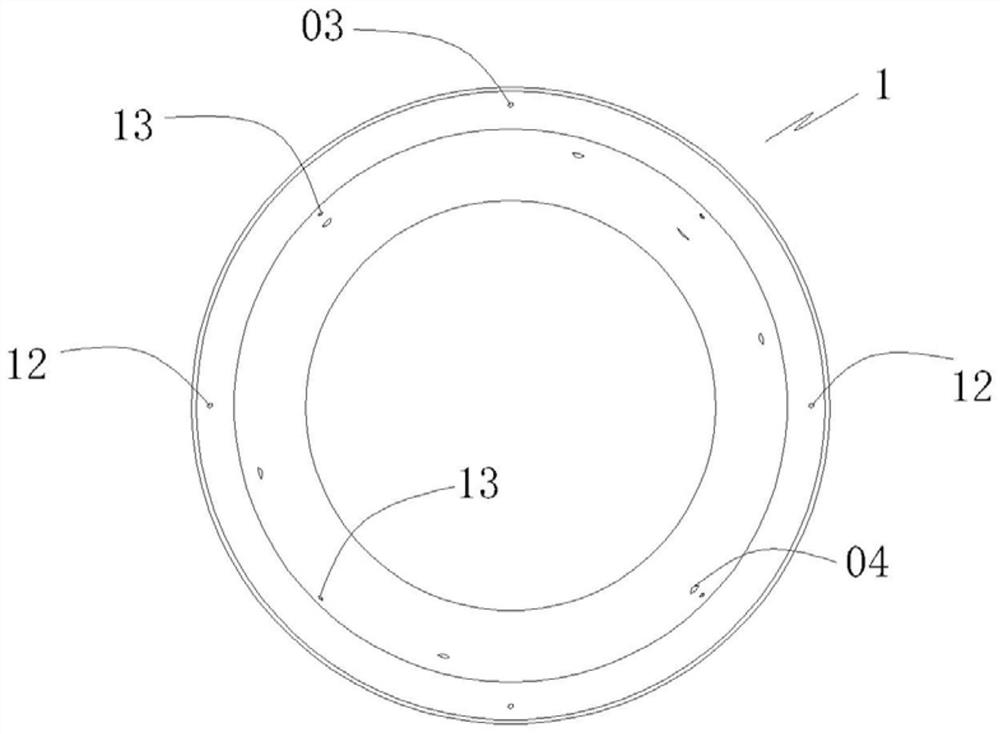

[0034] Please refer to Figure 1 to Figure 5 , a cooling water spray member for laser cutting in this embodiment, the spray member 1 is an annular cylindrical member with a vertical through hole in the middle, an annular water tank 11 is opened inside the spray member 1, and a bottom surface of the spray member 1 is provided with Several small spray holes 12 at the bottom of the annular water tank 11 are connected. The inner wall of the spray member 1 is provided with a number of small spray holes 13 on the side wall of the annular water tank 11. The outer wall of the spray member 1 is provided with water inlets 14. The annular water tank 11 It communicates with the water inlet hole 14; the spray member 1 is set on the outer periphery of the laser cutting head.

[0035] As a preferred embodiment, the lower part of the inner wall of the spray member 1 is set as an inverted cone surface, and the angle between the inverted cone surface and the vertical direction is 15°-45°; or, t...

Embodiment 2

[0043] Please refer to Figure 8 and Figure 9 , a cooling water spraying device for laser cutting in this embodiment, including the spraying member 1 described in the first embodiment.

[0044] And include: component water inlet valve 2, water delivery pipe 3 and water tank 4, component water inlet valve 2 is installed on the outside of spraying component 1, and the water outlet end of component water inlet valve 2 is connected with water inlet hole 14, and component water inlet valve 2 The water inlet end is connected with the water tank 4 through the water delivery pipe 3. The top of the water tank 4 is provided with an air blowing port 41, and the air blowing port 41 communicates with an external compressed air source.

[0045] Preferably, the top of the water tank 4 is provided with a water inlet 42 , the bottom of the water tank 4 is provided with a water outlet 43 , and the water delivery pipe 3 is connected to the water outlet 43 .

Embodiment 3

[0047] Please refer to Figure 1 to Figure 9 , a laser cutting machine of this embodiment, the laser cutting machine includes the cooling water spraying device as described in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com