Three-dimensional garage vehicle carrying board with reversing limiting function

A technology of three-dimensional garages and vehicle boards, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve the problems of not being able to deal with the problem of being too deep in the warehouse and sticking out the vehicle boards from the rear, so as to achieve easy layout and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

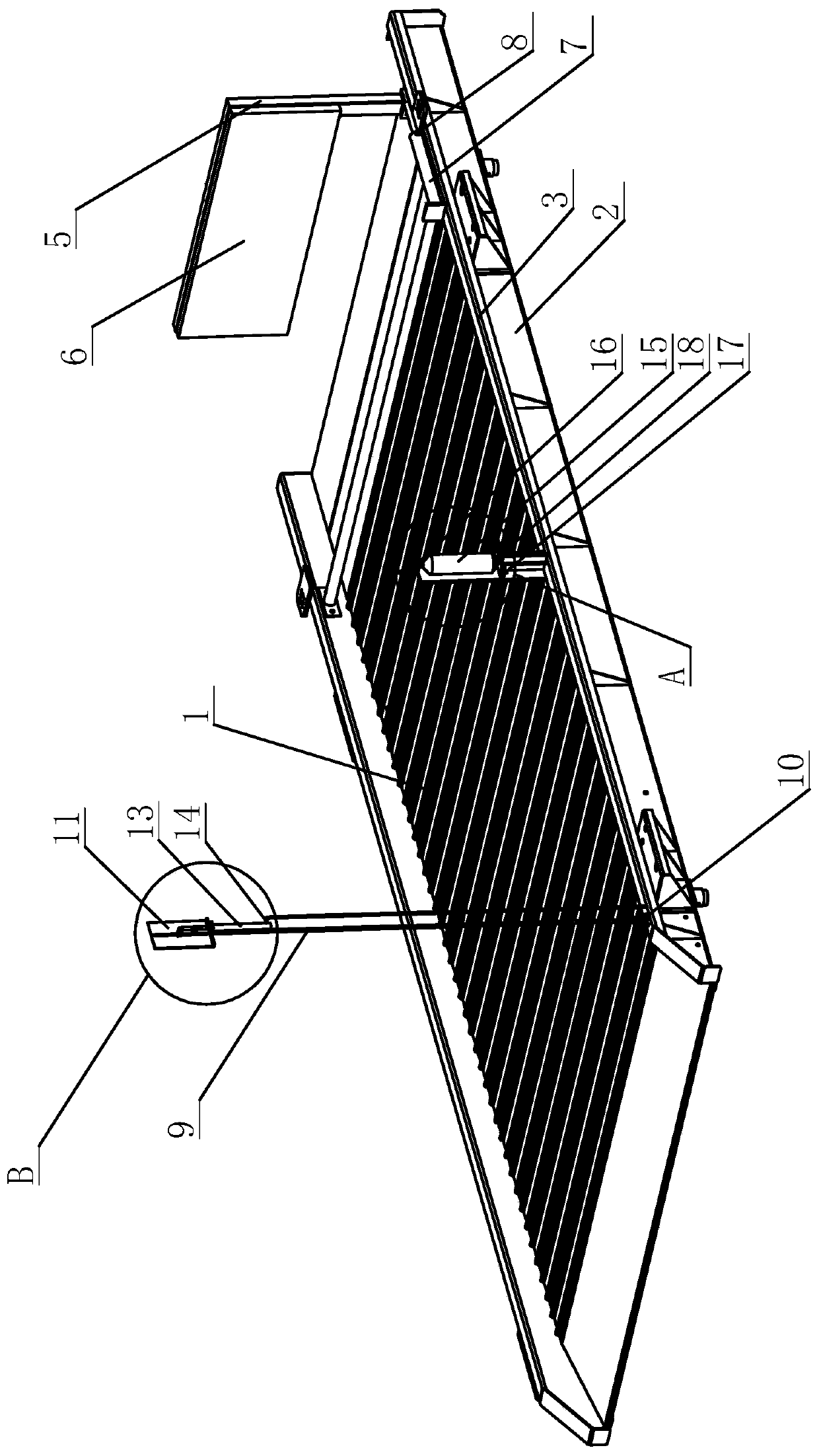

[0038] Example 1: A car-carrying board in a three-dimensional garage with a reverse limit function

[0039] This example combines physical protection and reversing prompts to form intuitive and clear feedback to the driver on the relative positional relationship between the rear of the vehicle and the vehicle-carrying board. Using this design can ensure that the rear of the vehicle protrudes out of the rear edge of the vehicle-carrying board caused by the vehicle being stored too deep problems, to eliminate related safety hazards and property losses.

[0040] The specific addition and improvement structure of this design lies in the limit mechanism installed on both sides or one side of the vehicle board. The specific structure used includes: trigger module, self-balancing transmission module, and response module.

[0041] 1) Trigger module

[0042] The trigger module is arranged on the frame 3 of the tail of the vehicle-carrying board body, and is used to physically judge the ...

Embodiment 2

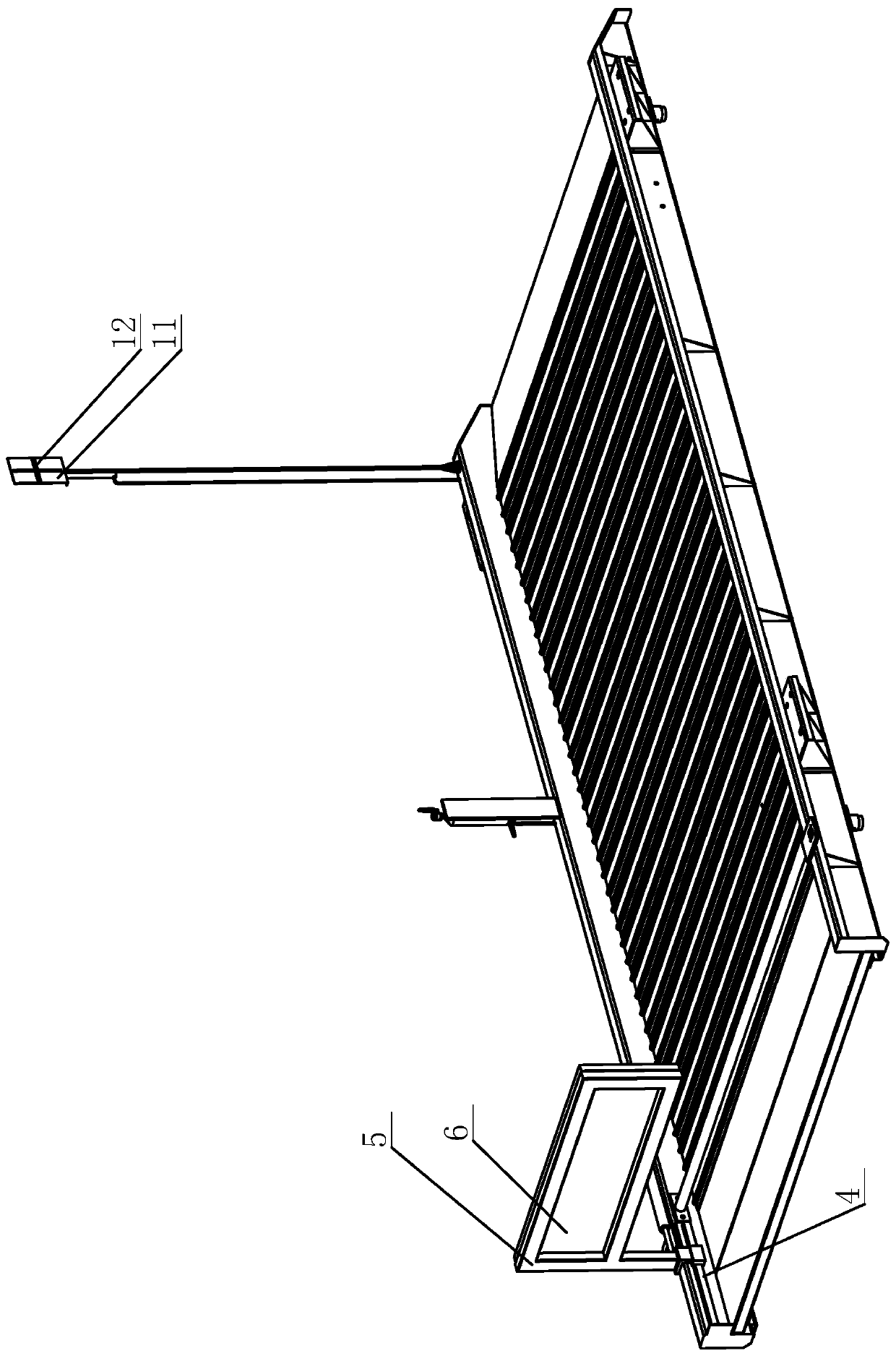

[0066] It is similar to the structure of embodiment 1, the difference is:

[0067] Both sides of the vehicle-mounted board main body 1 of embodiment 2 are provided with a limit mechanism. On specific structural parameters, the vertical distance between the inside side walls of the limit plate 6 on both sides and the central position of the vehicle-mounted plate is 5 cm. 6 The inner distance is 10cm, which can be effectively close to the center of the rear of the vehicle, and can form a good contact and cooperation with the rear of the vehicle no matter when the vehicle is reversed into the garage on the left side or reversed into the garage on the right side.

[0068] In order to prevent extreme serious driving mistakes, a limit bar is set at the rear of the vehicle plate, the height of the limit bar is 20cm from the upper surface of the vehicle plate, and the two ends of the limit bar are respectively fixed on the same side. On the side baffle 2, the limit bar is used to bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com