Grain sampling and monitoring device for combine harvester and control method for grain sampling and monitoring device

A technology of combine harvester and monitoring device, which is applied in the fields of harvester, application, agricultural machinery and implements, etc., can solve the problems of unsatisfactory grain monitoring effect, affecting production operation efficiency, unable to feedback information, etc., so as to ensure the real-time monitoring effect, Easy to promote and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Grain Sampling Monitoring Device for Combine Harvesters

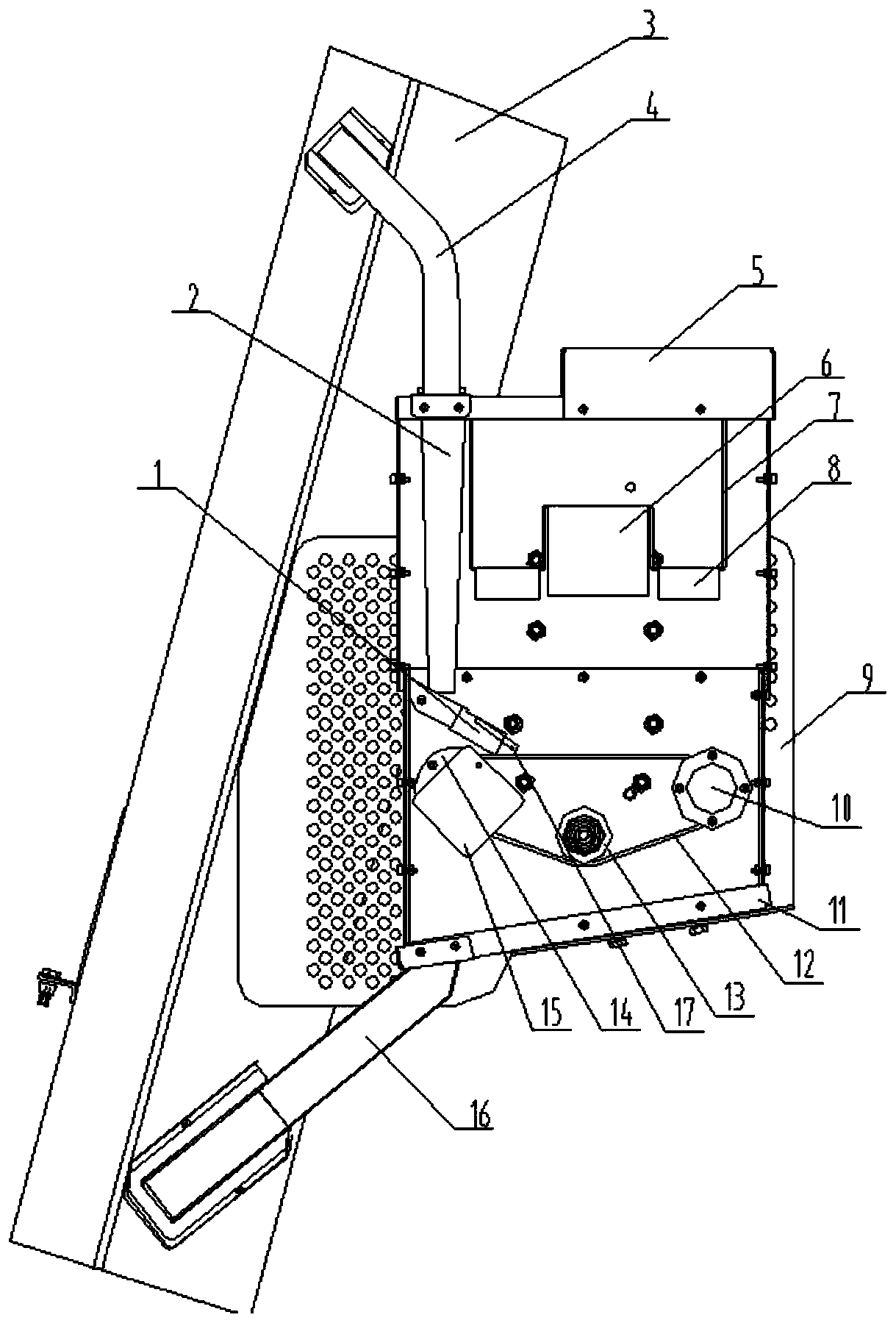

[0028] Such as figure 1 As shown, the grain elevator 3 is included, and the grain elevator 3 is installed on the combine harvester, and is used to transport the processed grain (grain) from the cleaning room located at the lower part of the combine harvester to the upper part of the combine harvester. The grain tank, this is prior art.

[0029] Such as figure 1 As shown, the upper side of the grain elevator 3 is connected to the upper end of the upper chute 4, the upper chute 4 is arranged obliquely, and the lower end of the upper chute 4 is connected to the sampling device, and the top of the sampling device is provided with a camera 6 and light supplement The light 8, the photographing camera 6 and the fill light 8 are fixed on the camera bracket 7. During implementation, two supplementary lights 8 are fixed on both sides of the camera bracket 7 , and the photographing camera 6 is fixed between the two suppl...

Embodiment 2

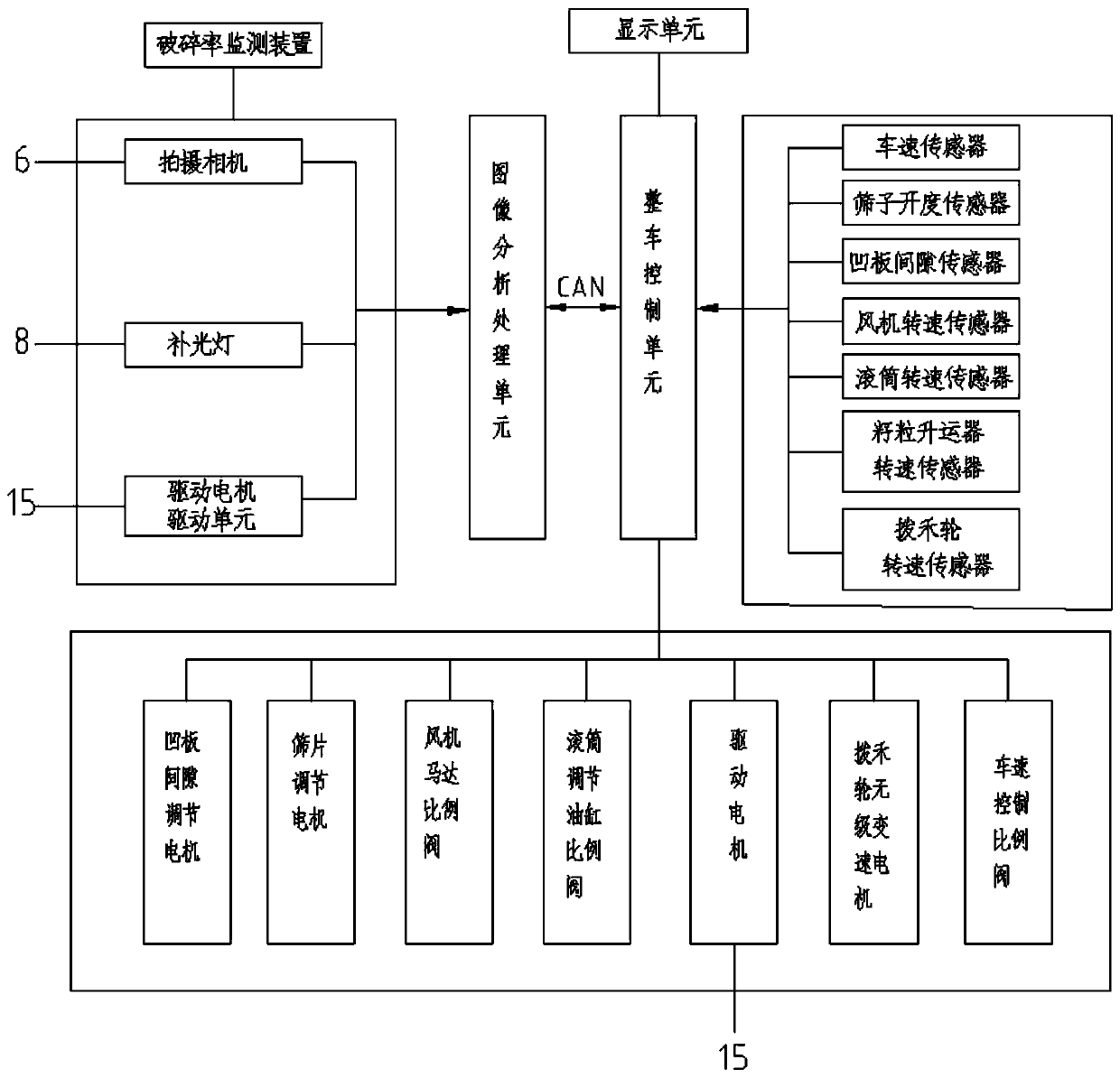

[0033]Control method of grain sampling monitoring device for combine harvester

[0034] When the speed of the grain elevator is normal, the vehicle control unit controls the sampling device to take samples; the camera captures the image of the sampled grain, and the image analysis and processing unit analyzes and processes the captured image, marking the image as containing impurities and damaged grains, and the vehicle control unit according to The analysis and processing results monitor the impurity rate and breakage rate of the grains; when the rotation speed of the grain elevator is abnormal, the vehicle control unit controls the sampling device to stop sampling. When the camera captures the image of the sampled grains, the control unit of the whole vehicle controls to turn on the supplementary light.

[0035] The control process is detailed below:

[0036] When the processed grain (grain) is transported to the grain tank by the grain elevator 3, the grain elevator 3 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com