Prefabricated stair component mechanical property detection system

A detection system and component technology, applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, scientific instruments, etc. Improve loading accuracy, prevent interference, and increase structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

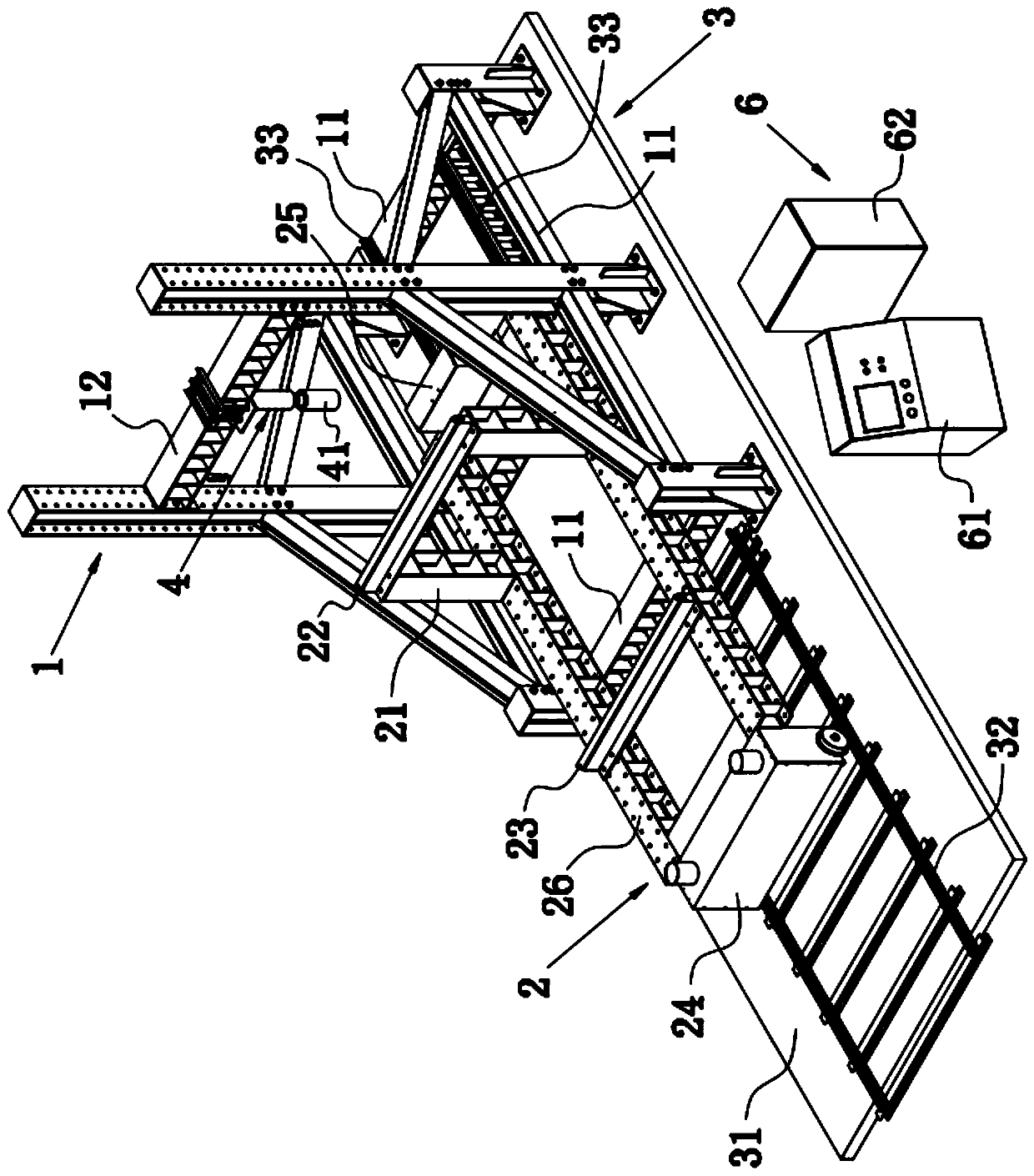

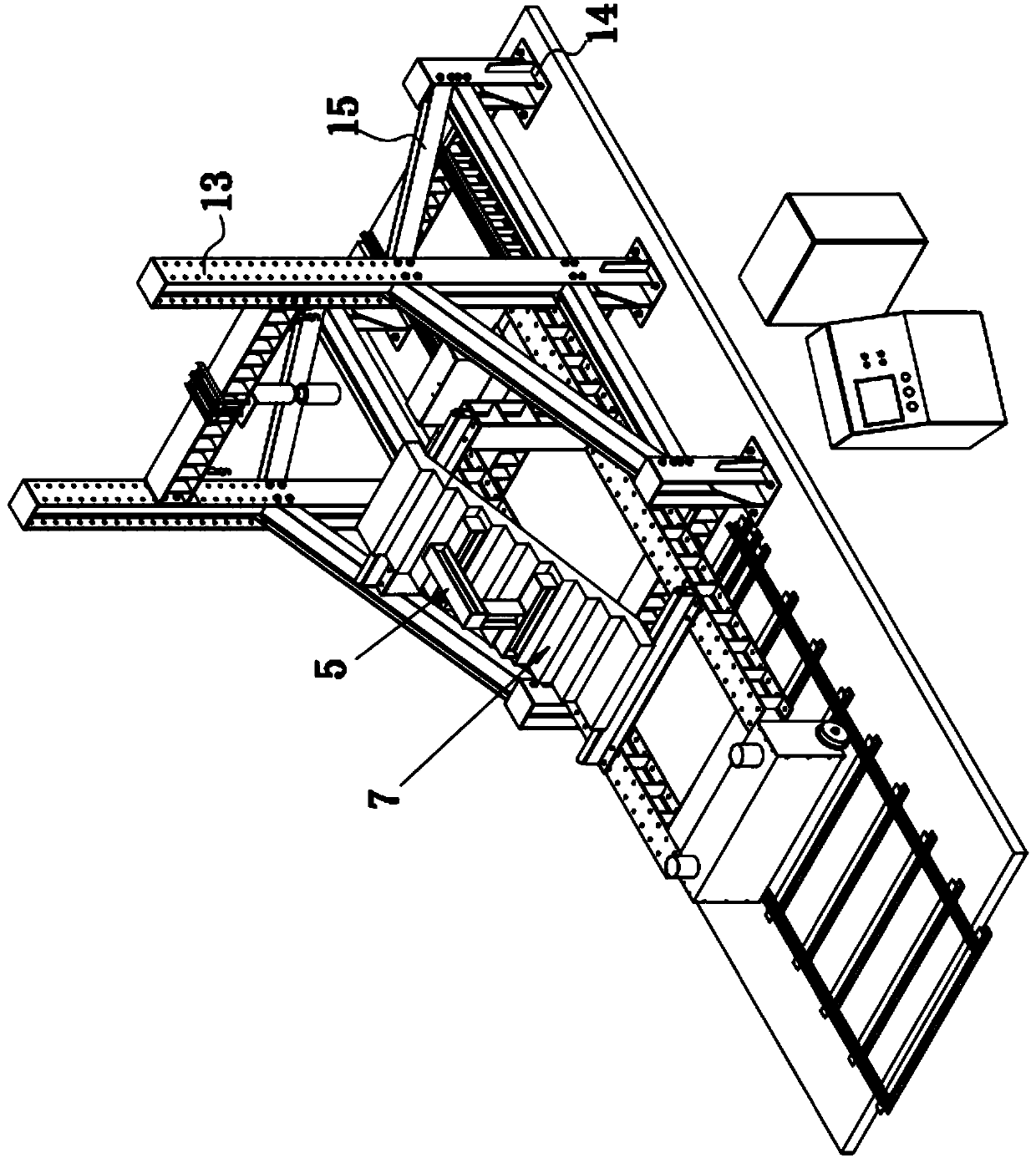

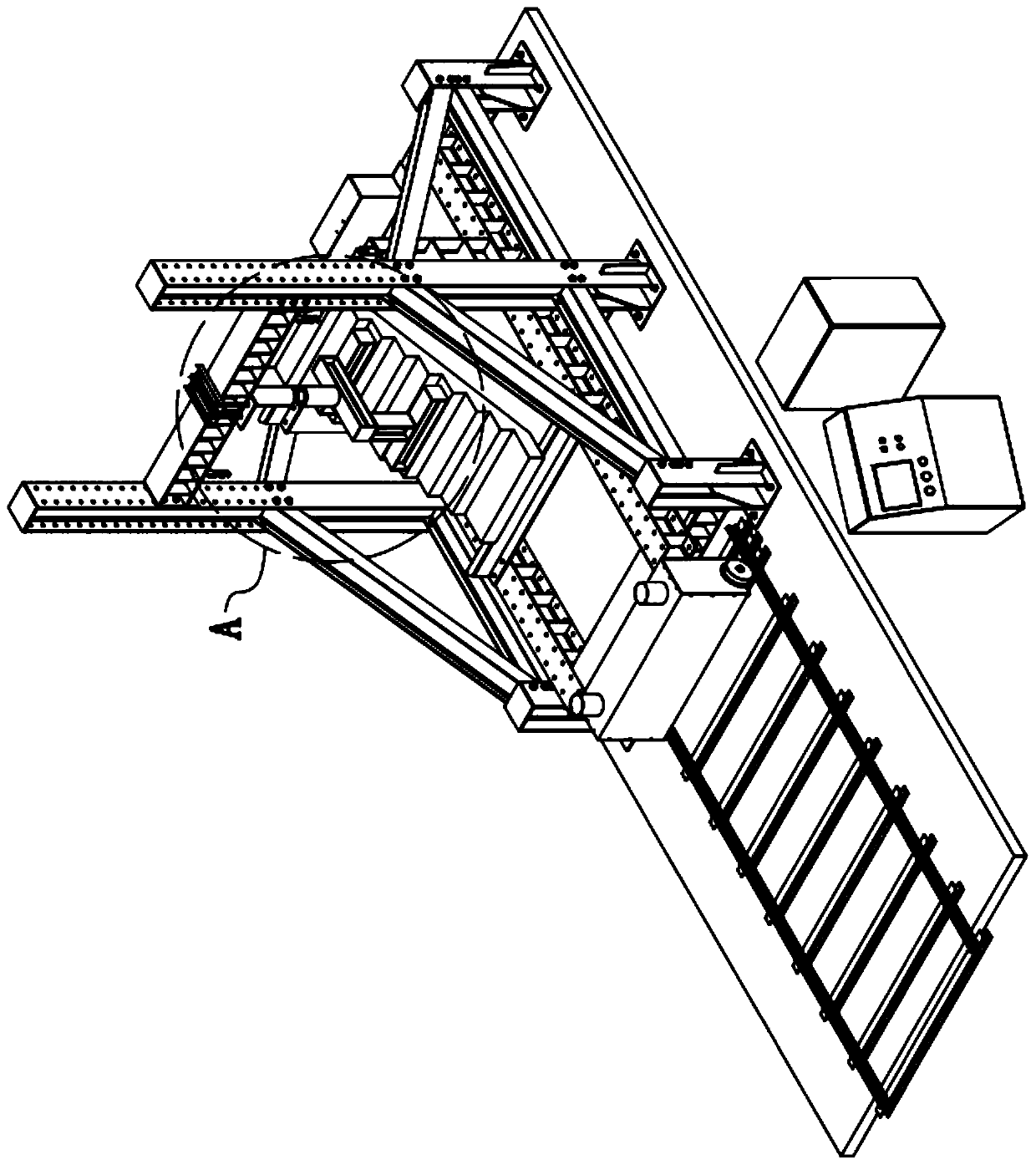

[0036] In order to achieve the purpose of the present invention, a prefabricated staircase component mechanical performance testing system includes: a pressing mechanism, which uses hydraulic pressure to apply a vertical downward pressure to the staircase component 7; The horizontal translation degree of freedom that moves out directly below the pressing mechanism; the translation load-bearing mechanism also has rollers that are in contact with the lower surface of the staircase member 7, and the rollers include upper rollers 22, lower rollers 23, and upper rollers 22 that are horizontal and parallel to each other. , the lower rollers 23 are not at the same level and all form line contact with the stair member 7; the pressure transmission member 5 is arranged between the pressing mechanism and the stair member 7, and the lower surface of the pressure transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com