Coal rock circulation friction-gas seepage coupling test device and test method

A gas seepage and test device technology, which is applied in the field of mining and rock mechanics, can solve the problems of lack of test devices, inability to describe the friction and slip characteristics and seepage characteristics, and sealing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

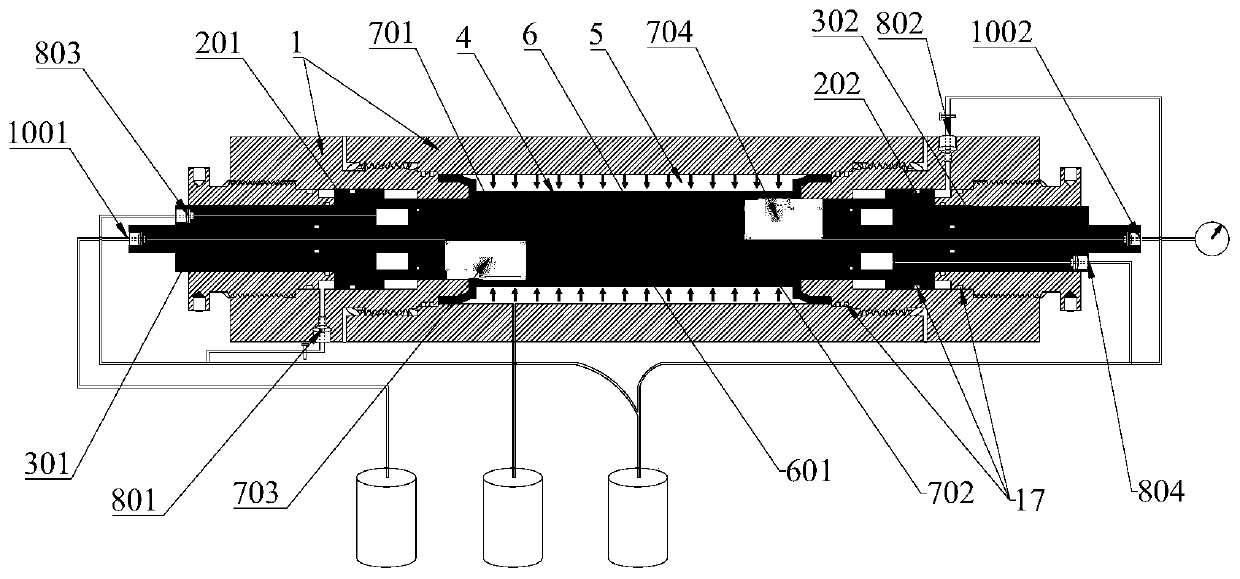

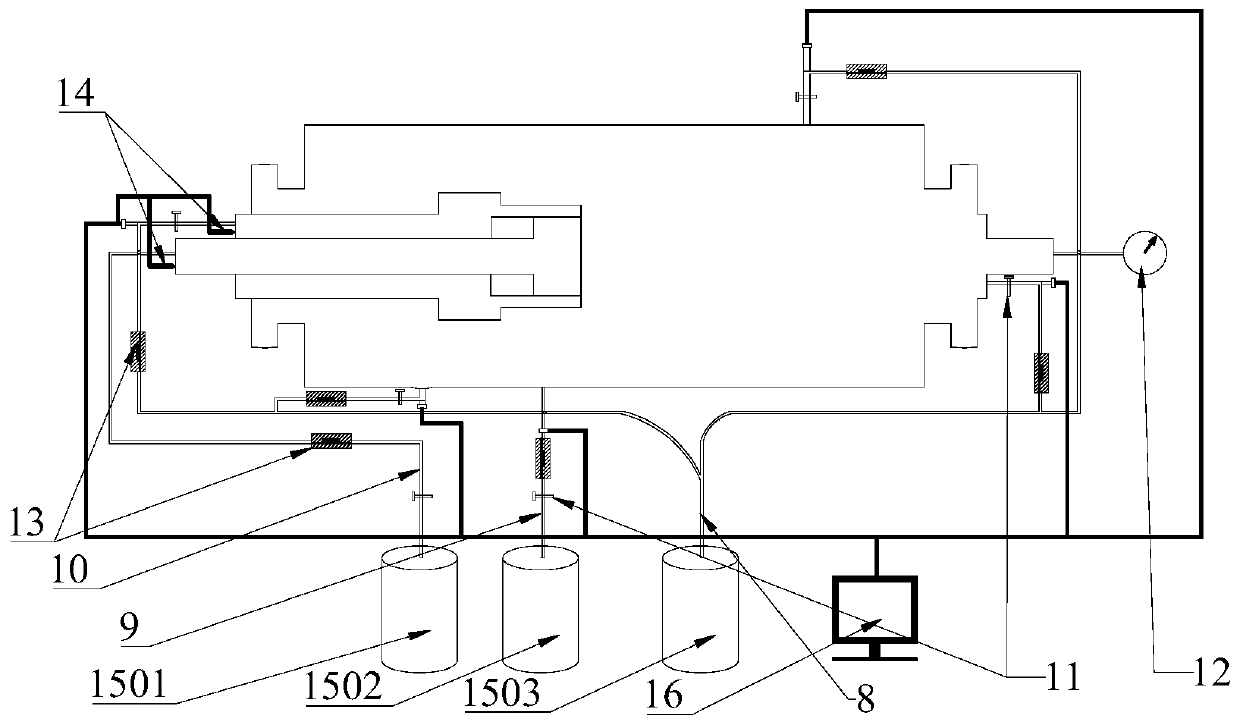

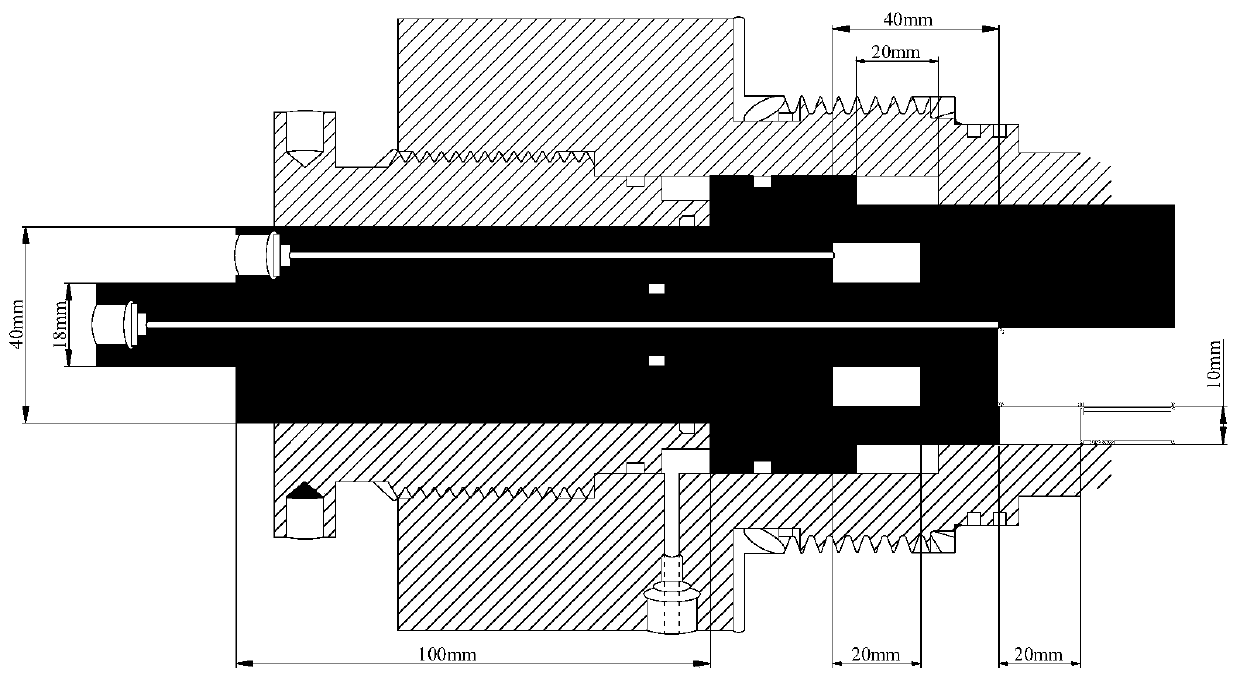

[0038] Such as figure 1 and figure 2 As shown, a coal-rock circulation friction-gas seepage coupling test device and test method include a coal-rock circulation friction system, a gas injection and pressurization system, and a real-time data acquisition system. The coal-rock circulation friction system includes a device outer shell 1 , the first axial loading cylinder 2, the second axial loading cylinder 3, the sealing rubber film 4, the confining pressure chamber 5, the test chamber 6, the clamping pad 7; the first axial loading cylinder 2 and the second axial loading oil cylinder 3 each have two independently controlled oil cylinders and are respectively located on both sides of the device, wherein the second axial loading oil cylinder 3 is nested inside the first axial loading oil cylinder 2; the test chamber The chamber 6 is located in the center of the device, and the clamping pad 7 is located between the inner side of the axial loading cylinders 2, 3 and the test chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com