Highway asphalt pavement repairing construction device and construction method thereof

A technology of asphalt pavement and construction device, applied in the field of road repair, can solve the problems of low efficiency, time-consuming and laborious, and uniform concrete surface, and achieves the effect of convenient operation, simple and convenient operation, and improved rolling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

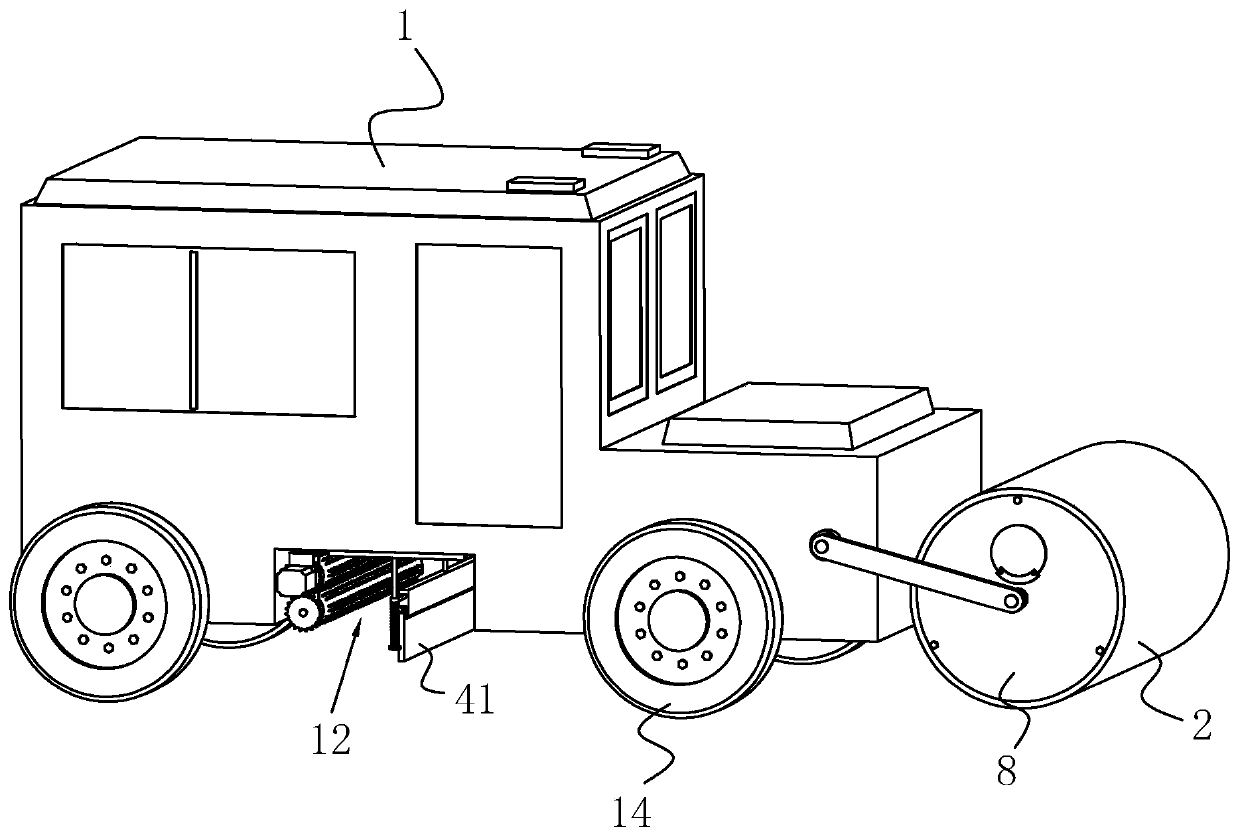

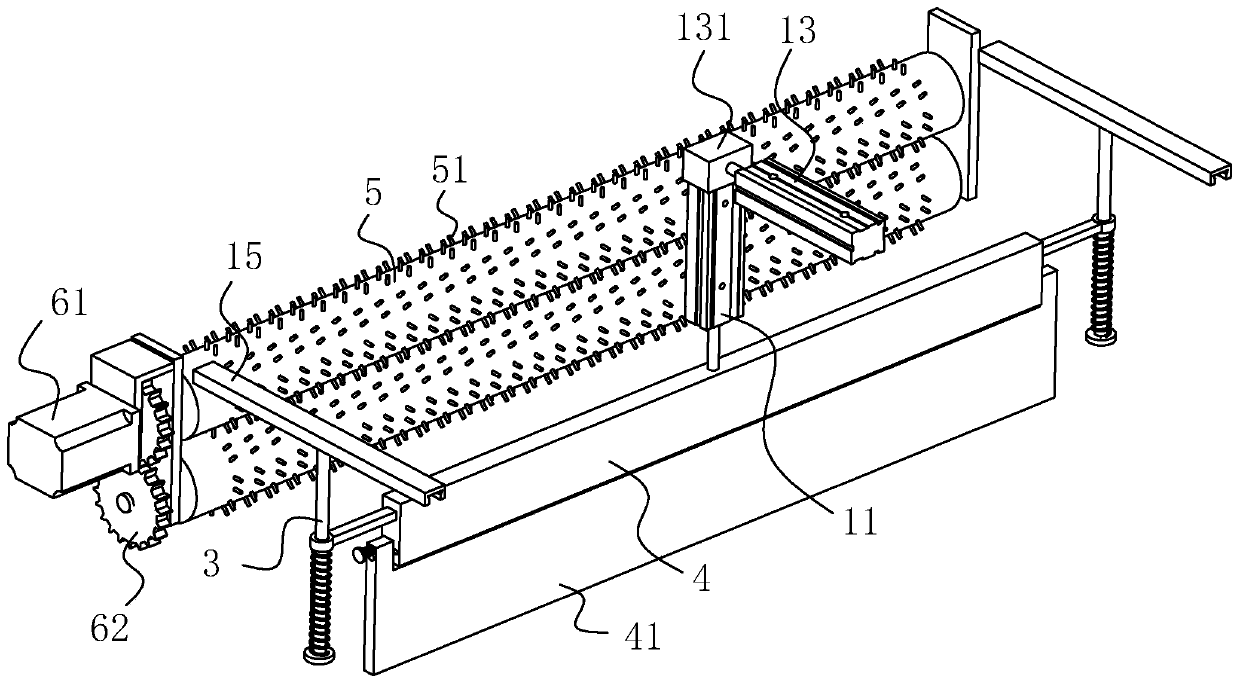

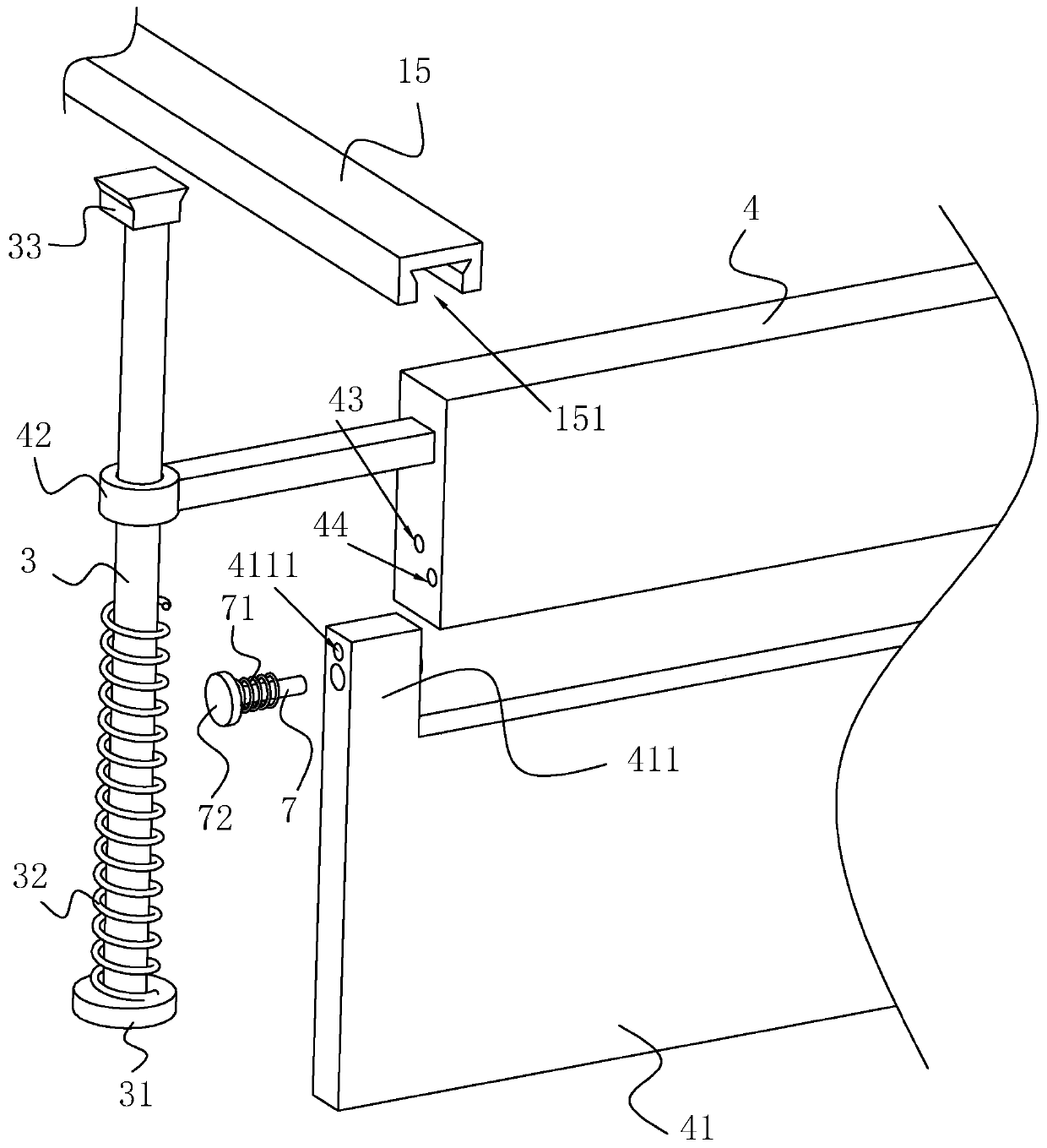

[0047] like figure 1 , 2 As shown, a road asphalt pavement repairing construction device includes a moving base 1, a roller 14 is arranged on the moving base 1, and a roller 2 for rolling the road surface is arranged on the moving base 1 to rotate. The bottom wall of the mobile seat 1 is provided with a column 3 extending downwards in the vertical direction. The upper slide is provided with a mounting plate 4, and the mounting plate 4 is provided with a scraper 41 for scraping the road surface.

[0048] like figure 2 , 3 As shown, the two ends of the mounting plate 4 are fixedly provided with collars 42 , the collars 42 are slidably sleeved on the column 3 , and the bottom of the column 3 is fixedly provided with a limiting platform 31 . The moving seat 1 is provided with a driving source for driving the mounting plate 4 to slide along the column 3 , and the driving source is an air cylinder 11 . The piston rod of the cylinder 11 is fixedly connected with the mounting pl...

Embodiment 2

[0062] A highway asphalt pavement repair construction method, comprising the following steps:

[0063] S1. Remove garbage or sundries from the potholes to be repaired;

[0064] S2, pouring concrete in the pothole;

[0065] S3, carry out construction by a kind of highway asphalt pavement patching construction device as any one of claims 1-9;

[0066] S31, first drive the scraper 41 to move in the vertical direction through the driving source, and adjust the distance between the scraper 41 and the road surface. At this time, the distance between the scraper 41 and the road surface that does not need to be repaired is 3mm-5mm, and the mobile seat 1 is moved. Make scraper 41 scrape the concrete surface after patching;

[0067] S32, move the moving seat 1 again, so that the roller 2 can initially roll the repaired concrete;

[0068] S33, drive the scraper 41 to move downward again until the scraper 41 conflicts with the road surface that does not need to be repaired, and scrapes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com