Circumferential feeding device for cross wedge rolling

A technology of feeding devices in the circumferential direction, applied in the direction of feeding devices, metal rolling, metal processing equipment, etc., can solve the problems of lengthening the ejector rod, increasing the length of the overall equipment, the difficulty of feeding materials, and large thrust, etc., to achieve The effect of saving equipment space, reducing width, and reducing load-bearing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the combination of technical features or technical features described in the following examples should not be considered isolated, they can be combined with each other to achieve better technical effects. In the figures of the following examples, the same reference numerals as those in the drawings represent the same features or components, which can be applied to different embodiments.

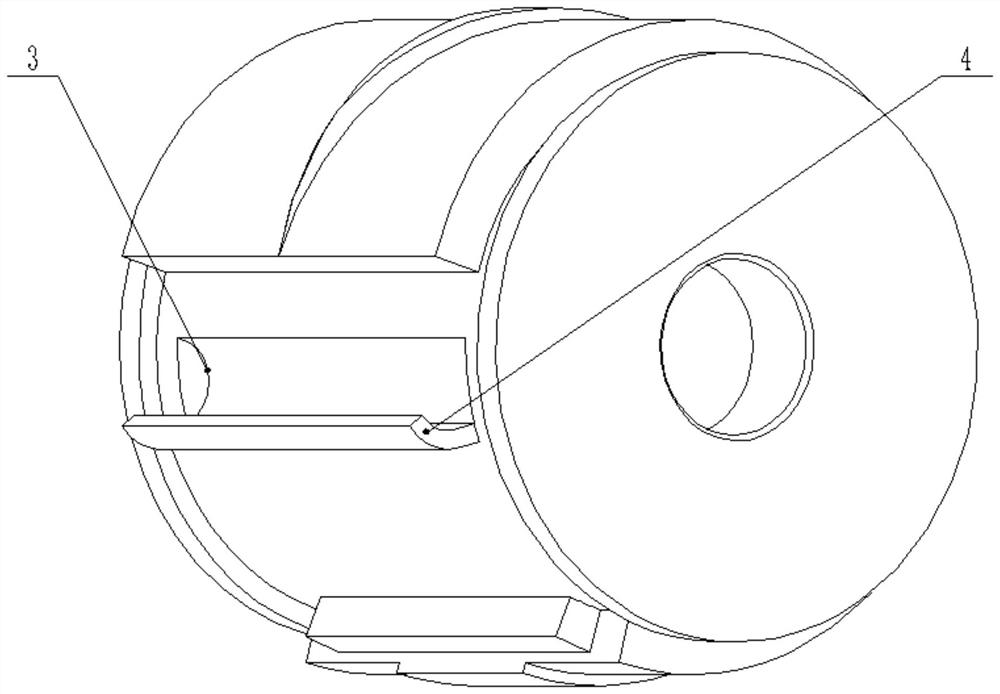

[0027] like figure 1 As shown, the embodiment of the present invention is a wedge-ranging circular direction feed device, which is particularly suitable for the feed of large shaft categories. The device includes a reference unit 1, a curved rail 2; a wedge rolling mill includes a top roll and a lower roll, the upper roller including the rolling section and the receiving section, the outer circumference of the rolling section is a top mold, the rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com