High-quality graded rice production and processing method

A processing method and rice technology, applied in application, grain processing, agriculture, etc., can solve problems such as human food waste, and achieve the effects of easy packaging, simple and practical process steps, and avoidance of food waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the drawings and embodiments.

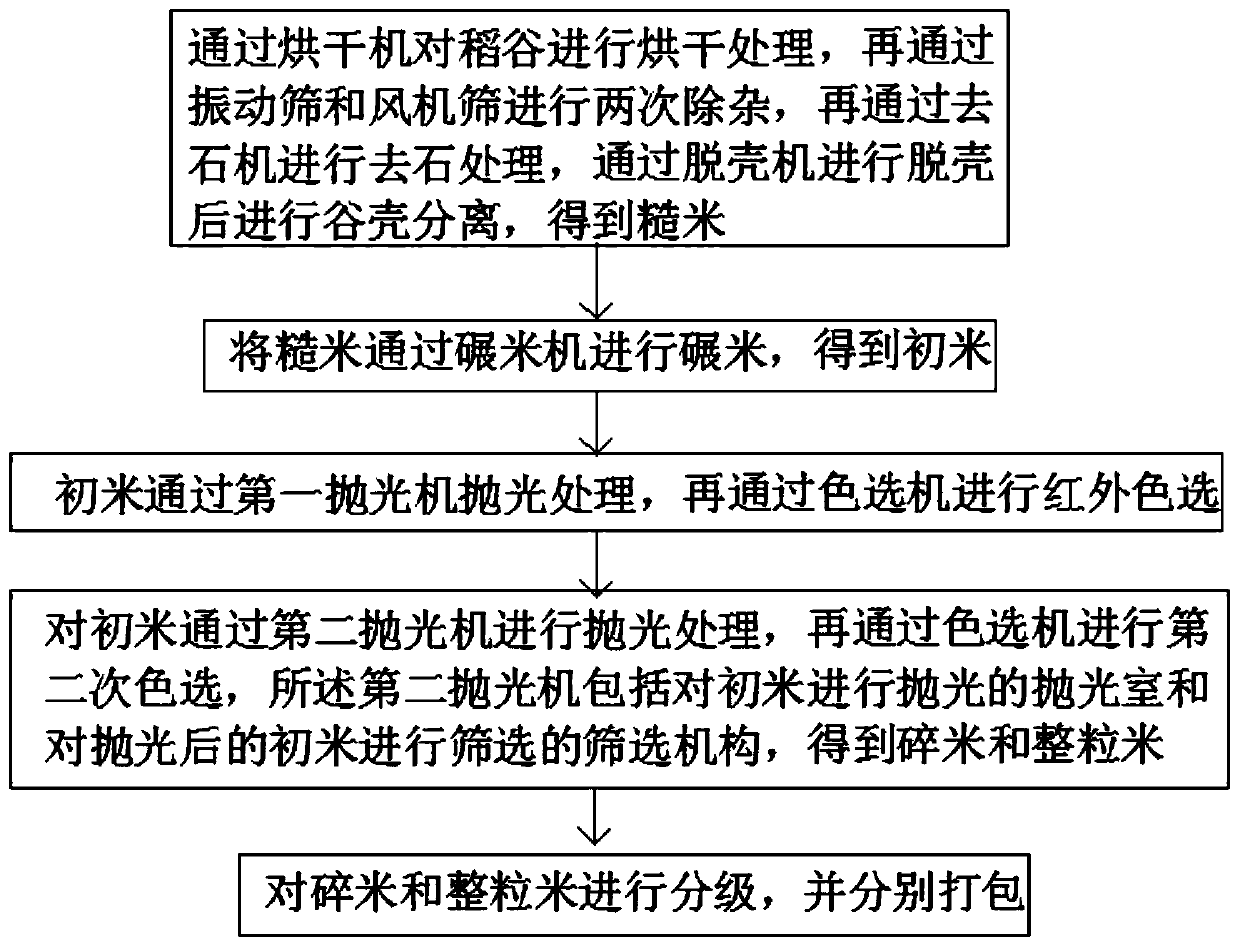

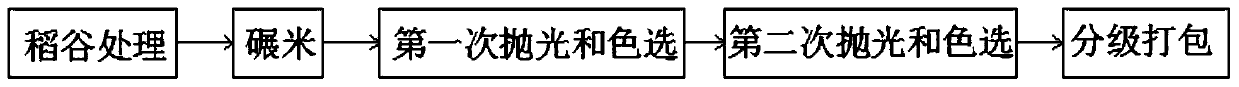

[0034] In an embodiment of the present invention, reference Figure 1 to Figure 3 , Provide a high-quality graded rice production and processing method, including the following steps:

[0035] S1. Rice processing: Dry the rice through a dryer, remove impurities twice through a vibrating screen and a fan sieve, then remove the stone through the stone remover, and remove the husk through the sheller Separated to obtain brown rice;

[0036] S2. Rice milling; the brown rice is milled through a rice mill to obtain the first rice;

[0037] S3. The first polishing and color sorting; the first rice is polished by the first polishing machine, and then infrared color sorting is performed by the color sorter;

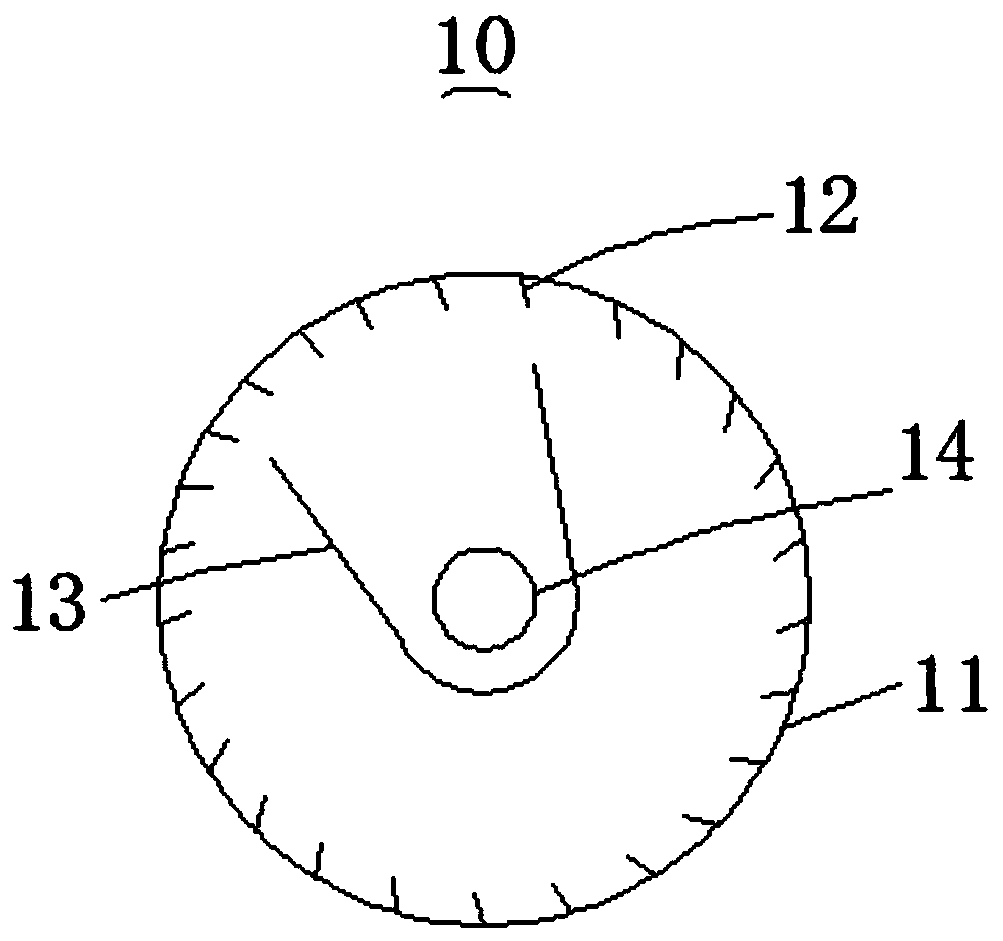

[0038] S4. The second polishing and color sorting; the first rice is polished by the second polishing machine, and then the second color sorting is performed by the color sorte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com