A preparation method of "j" type reinforced wall panel preform suitable for rfi process

A technology of reinforced wall panels and preforms, which is applied in the field of preparation of preforms to improve the quality of composite "J" type reinforced wall panels, which can solve the problems of weak impact damage resistance and poor performance, and reduce processing costs. Difficulty, avoid suture buckling, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

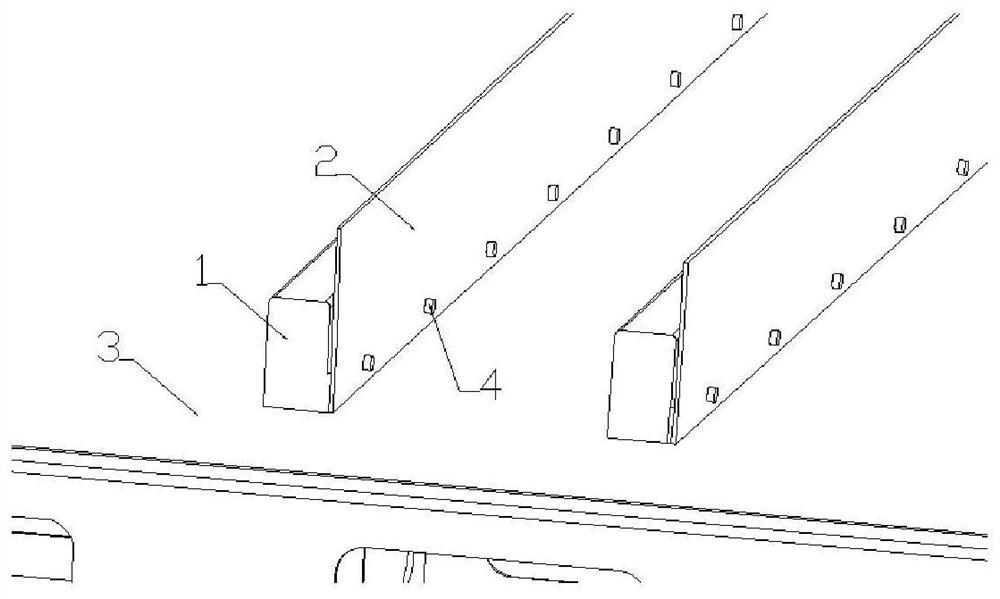

[0054] A method for preparing a "J" type reinforced wall panel preform suitable for RFI process, comprising:

[0055] (a) Decompose the "J" type reinforced wall plate according to the structural characteristics, and divide the "J" type long stringer ply unit according to the process separation surface.

[0056] (b) Design of preforming die for “J”-shaped trusses.

[0057] (c) "J" shaped stringer and skin unit preformed.

[0058] (d) Assemble the "J"-shaped stringer, the skin unit and the forming mold, pre-press and shape, and position to form a pre-formed "J"-shaped reinforced wall panel preform.

[0059] (e) The pre-formed "J"-shaped reinforced wall panel preform is sewed and trimmed to prepare a "J"-shaped reinforced wall panel preform.

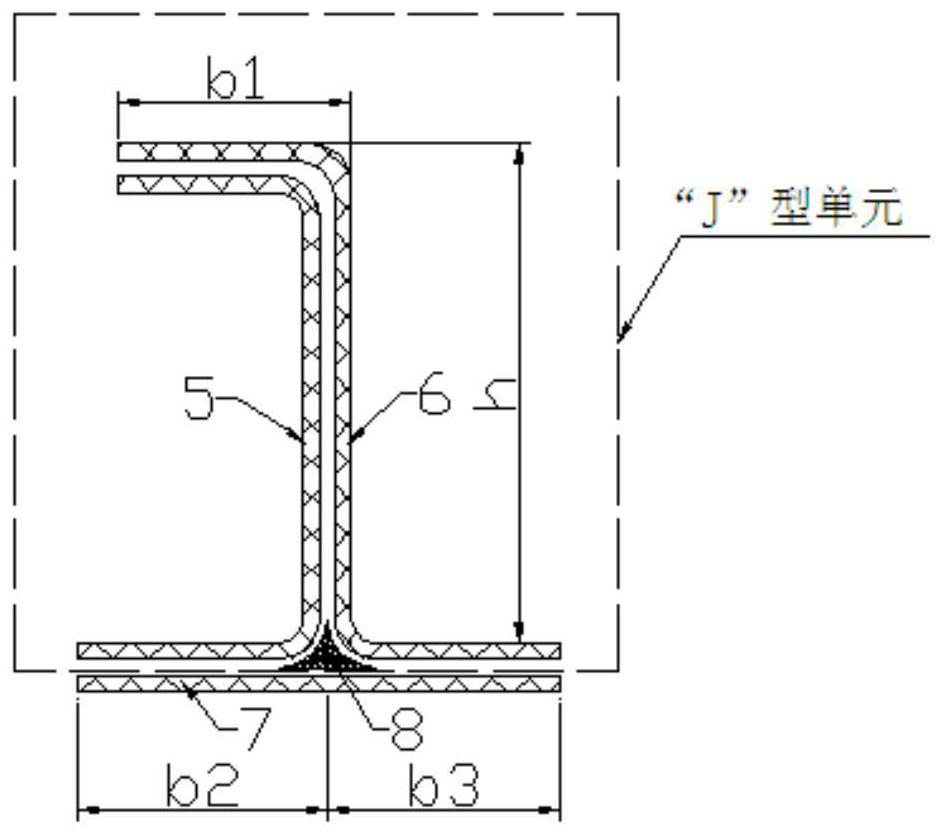

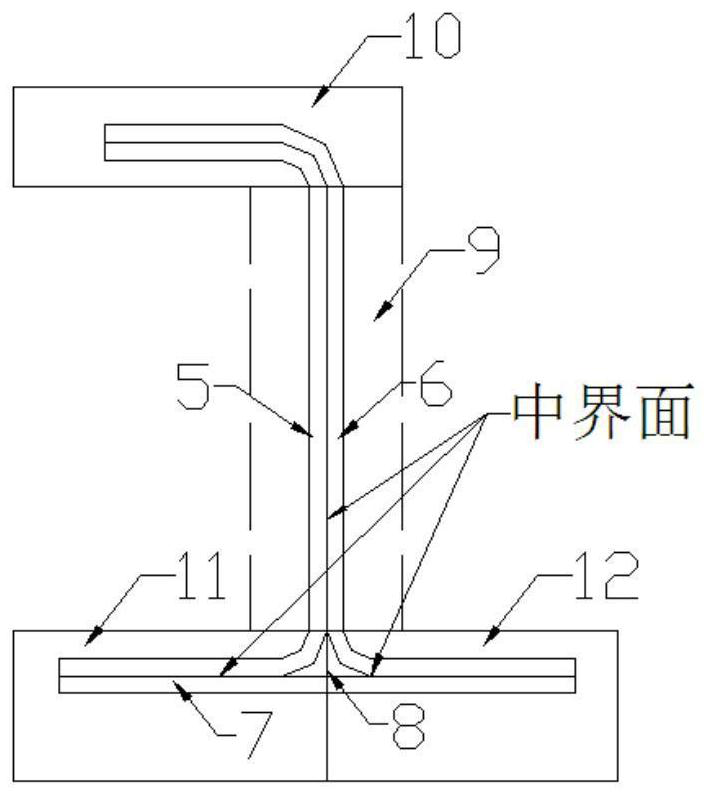

[0060] In step (a), the "J"-shaped reinforced panel unit is divided into two parts: a "J"-shaped stringer and a skin according to structural features. "J" type long stringer layup is divided into "C" type layup unit 5, "Z" type layup uni...

Embodiment 1

[0088] Example 1: A "J"-shaped reinforced wall panel, with a size of 2.0m×0.8m, has 6 "J"-shaped long stringers of the same length as the skin, and 6 long stringers have a fracture in the middle. The height of the truss is 45mm, the width of the upper and lower flanges is 20mm, and the radius of the corner between the web and the upper and lower flanges is 4mm. The thickness of the single layer of woven fabric used is 0.2mm, the skin has 16 layers of fiber woven fabric, the thickness is 3.2mm, the "J" type reinforcement has a total of 12 layers, the thickness is 2.4mm, and the inner side of the skin is 12 layers in the flanging area of the long stringer Participate in stitching, the outer 4 layers are not stitched, and are integrally formed through the RFI process. Considering the internal and external profile size, position, and appearance quality requirements of the "J"-shaped truss, this scheme is adopted to prepare the "J"-shaped composite material reinforced wall panel ...

Embodiment 2

[0113] Example 2: A "J"-shaped reinforced wall panel, with a size of 5.0m*0.9m, has 6 "J"-shaped reinforcements, the total length of the girder is 4.2m, the height of the girder is 40mm, and the width of the upper flange is 18mm , the width of the lower flanging on both sides is 25mm, and the r angle radius between the web and the upper and lower flanging is 3mm. The thickness of the single layer of woven fabric used is 0.16mm, the skin has 25 layers of fiber woven fabric with a thickness of 4.0mm, and a total of 12 layers of "J" type reinforcement with a thickness of 1.96mm. The lower flanging area of the "J"-shaped truss is sewn with the skin and formed as a whole through the RFI process. The inner cavity of the "J" type long truss is matched with multiple metal parts, and the fracture and both ends are matched with the beam, which puts forward higher requirements for the size, position and appearance quality of the reinforcement. The "J" type composite material The prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com