Laser welding tool for welding the stainless steel panel and the vertical barrel together

A laser welding and stainless steel technology, applied in laser welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of time-consuming and labor-intensive welding, low welding accuracy, etc., to ensure welding quality, high welding efficiency, Combines a tight and even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

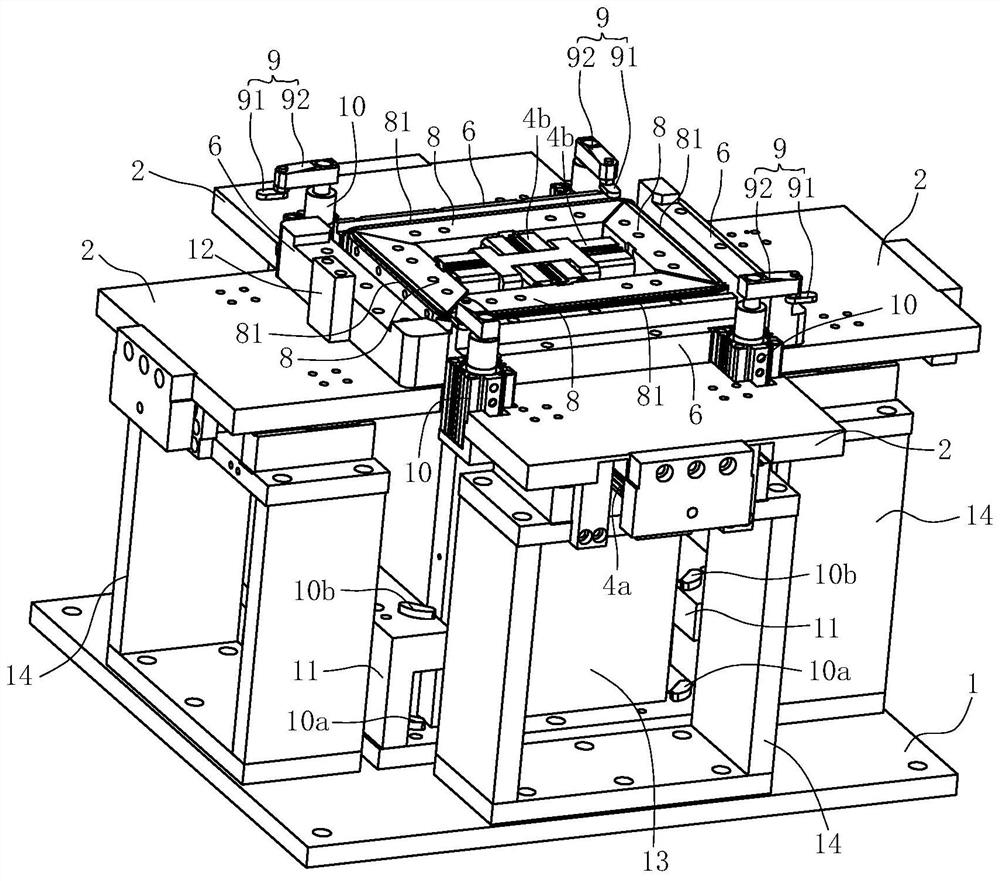

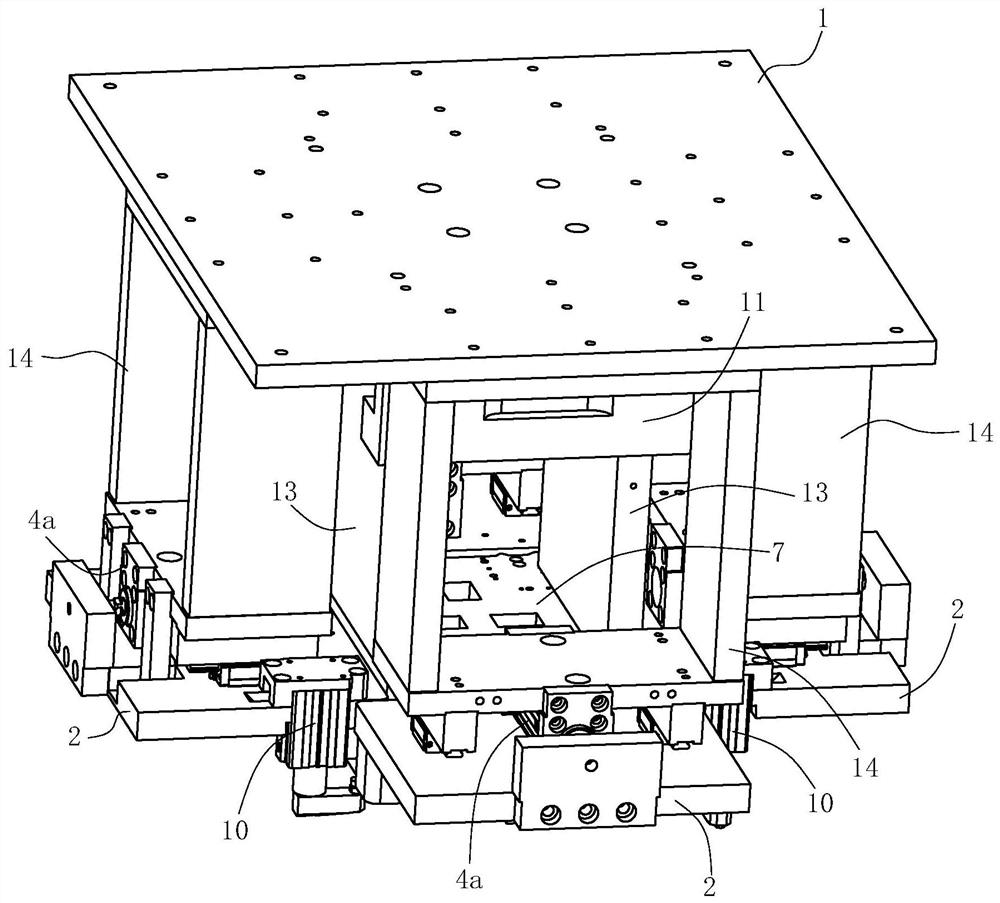

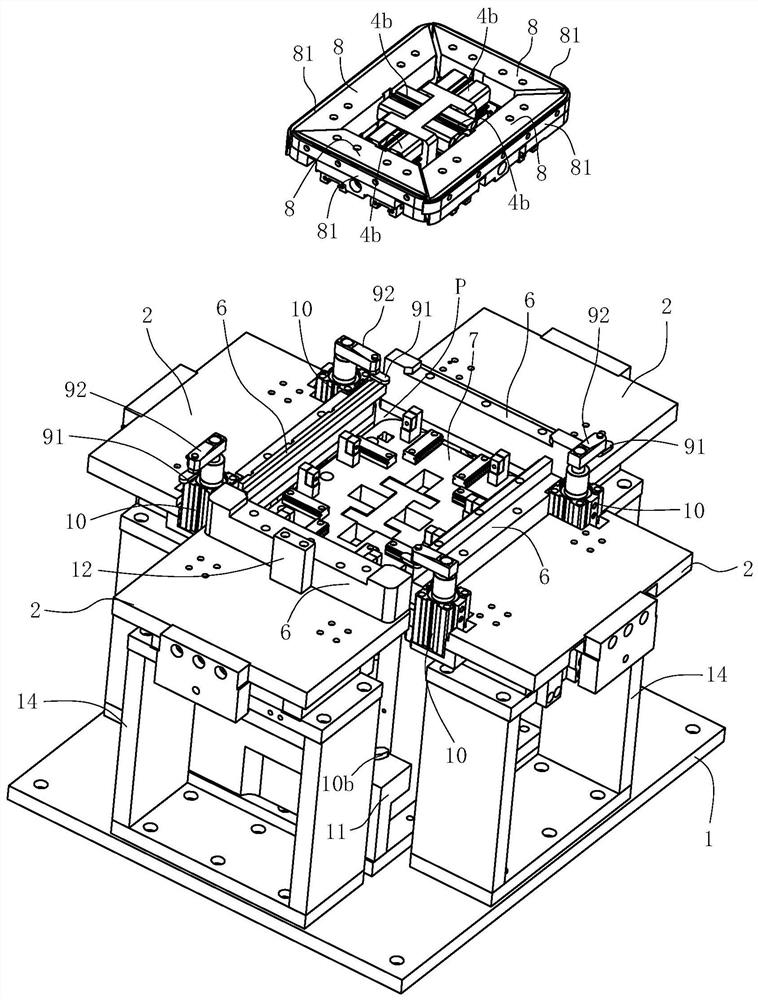

[0026] Such as Figure 1-8 Shown is a preferred embodiment of the present invention.

[0027] A laser welding tool that welds the stainless steel panel and the vertical barrel together. The welding tool realizes welding the vertical barrel 3 to the stainless steel panel 5. The welding position is arranged in a ring shape, and the vertical barrel 3 is in a ring shape with four corners inverted round. Such as Figure 7 As shown, the stainless steel panel 5 has a perforation 52 for the vertical bucket to pass through. The hole wall of the perforation 52 is welded to the upper opening periphery of the vertical bucket 3. The top surface of the stainless steel panel 5 is punched out with a concave annular groove 54. The ring groove 54 The inner wall constitutes the hole wall of the perforation 52 on the stainless steel panel 5, and the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com