Device for automatically shearing diversion connecting part of transformer substation

A technology for substation automation and connecting pieces, applied in the direction of shearing devices, driving devices, and knives for shearing devices, etc., can solve problems such as troubles and dangers, and achieve the effects of easy manufacturing, simple structure, and increased practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

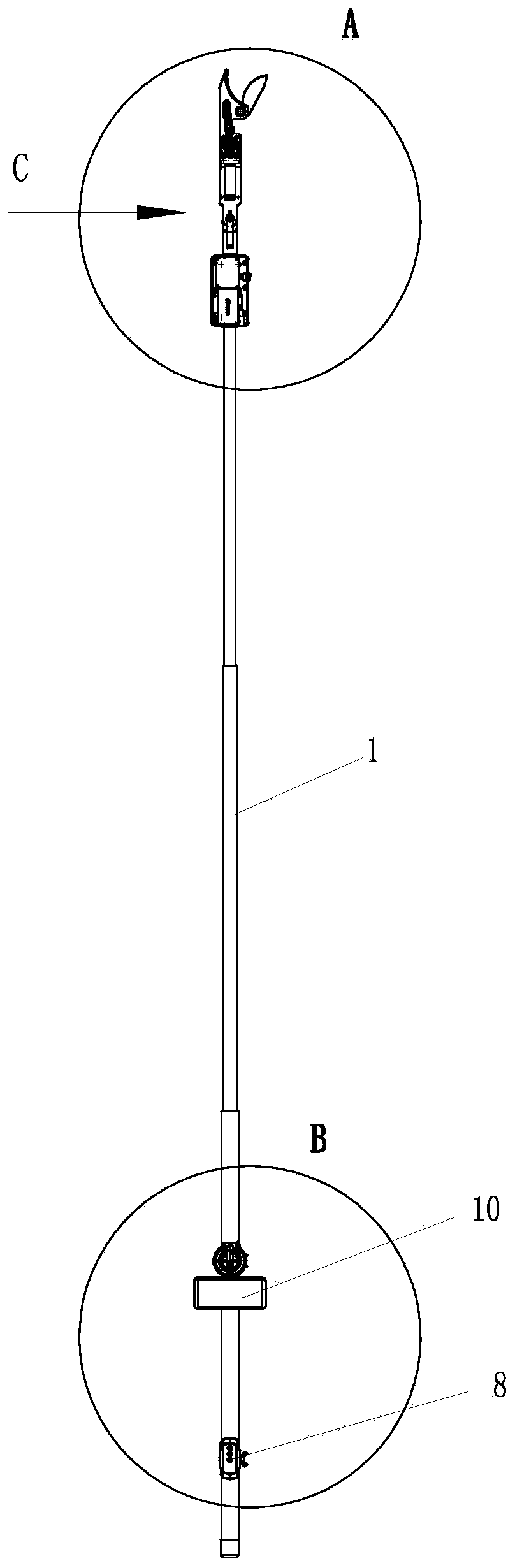

[0020] Please check Figure 1 to Figure 5 , a device for automatically cutting the guide connecting piece in a substation, which includes an insulating rod body 1, one end of the insulating rod body 1 is connected to a fixing bracket 13 through an adjusting bolt 12, and the end of the fixing bracket 13 is provided with a scissors mechanism 2. The bracket 13 is also provided with a crank structure 3, a flywheel mechanism 4, and a motor 5. The insulating rod body 1 is provided with a power supply module 6, a controller 7 and a remote controller 8. The scissor mechanism 2 includes two shear blades. The crank structure 3 The transmission input end of the crank structure 4 is hinged with the flywheel mechanism 4, the transmission output end of the crank structure 3 is movably connected with a shear blade, the motor 5 is connected with the flywheel mechanism 4, the motor 5 and the remote controller 8 are connected with the controller 7 respectively, The power supply module 6 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com