Glue spraying system and method for shoe sole processing

A technology for spraying glue and rubber shoes, which is applied in the direction of shoemaking machinery, footwear, applications, etc., can solve the problems of low work efficiency and low automation, and achieve the effect of improving the efficiency of glue spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

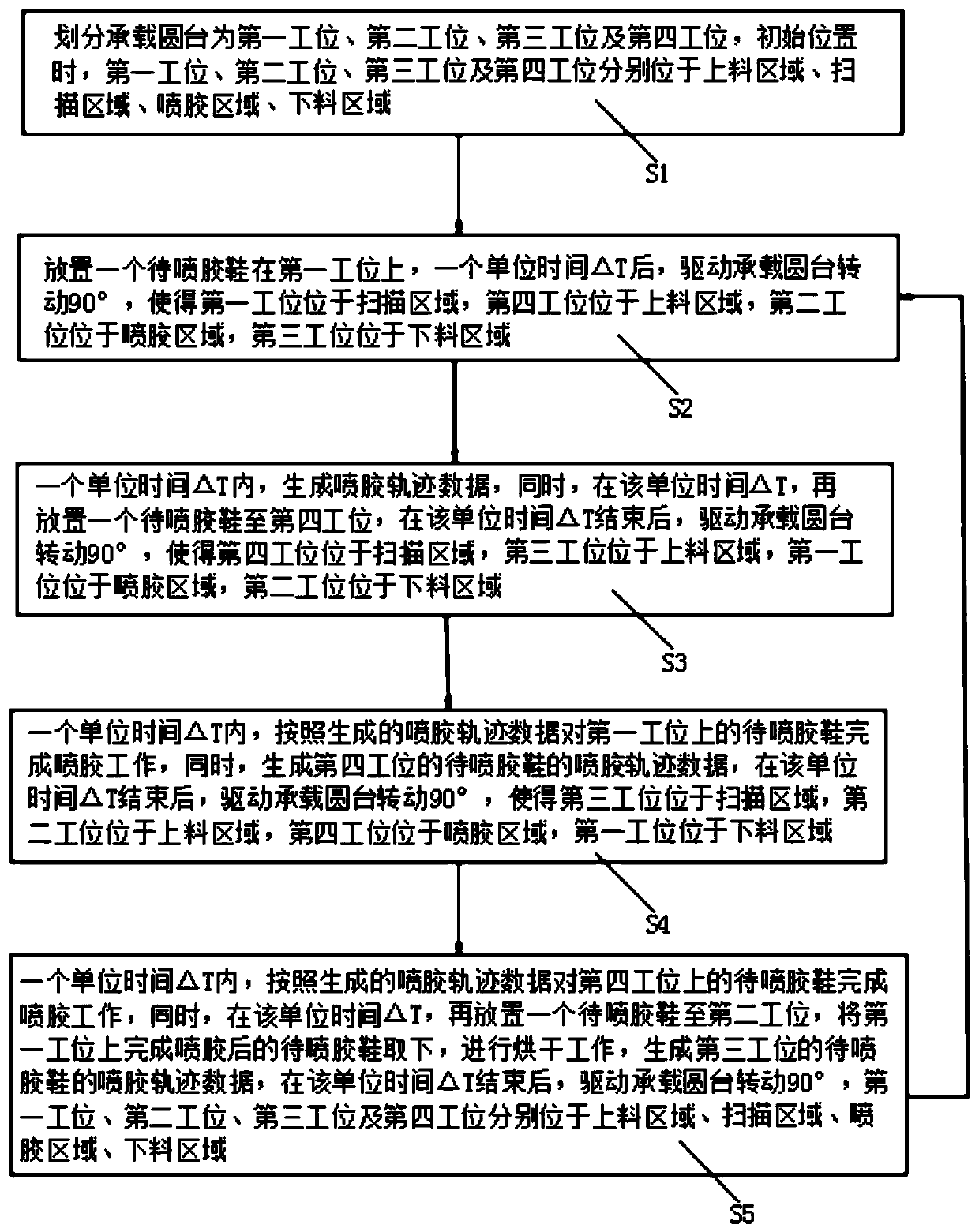

[0046] refer to figure 1 , a glue spraying method for shoe sole processing, comprising the following steps,

[0047] S1: Divide the carrying round table into the first station, the second station, the third station and the fourth station. In the initial position, the first station, the second station, the third station and the fourth station respectively Located in the loading area, scanning area, glue spraying area, and unloading area, execute S2;

[0048] S2: Put a rubber shoe to be sprayed on the first station, and after a unit time △T, drive the bearing round table to rotate 90°, so that the first station is located in the scanning area, the fourth station is located in the loading area, and the second station Located in the glue spraying area, the third station is located in the unloading area, execute S3;

[0049] S3: Within a unit time △T, project visible light, high-energy light beam, ultrasonic wave or X-ray onto the rubber shoes to be sprayed, and create the rubber...

Embodiment 2

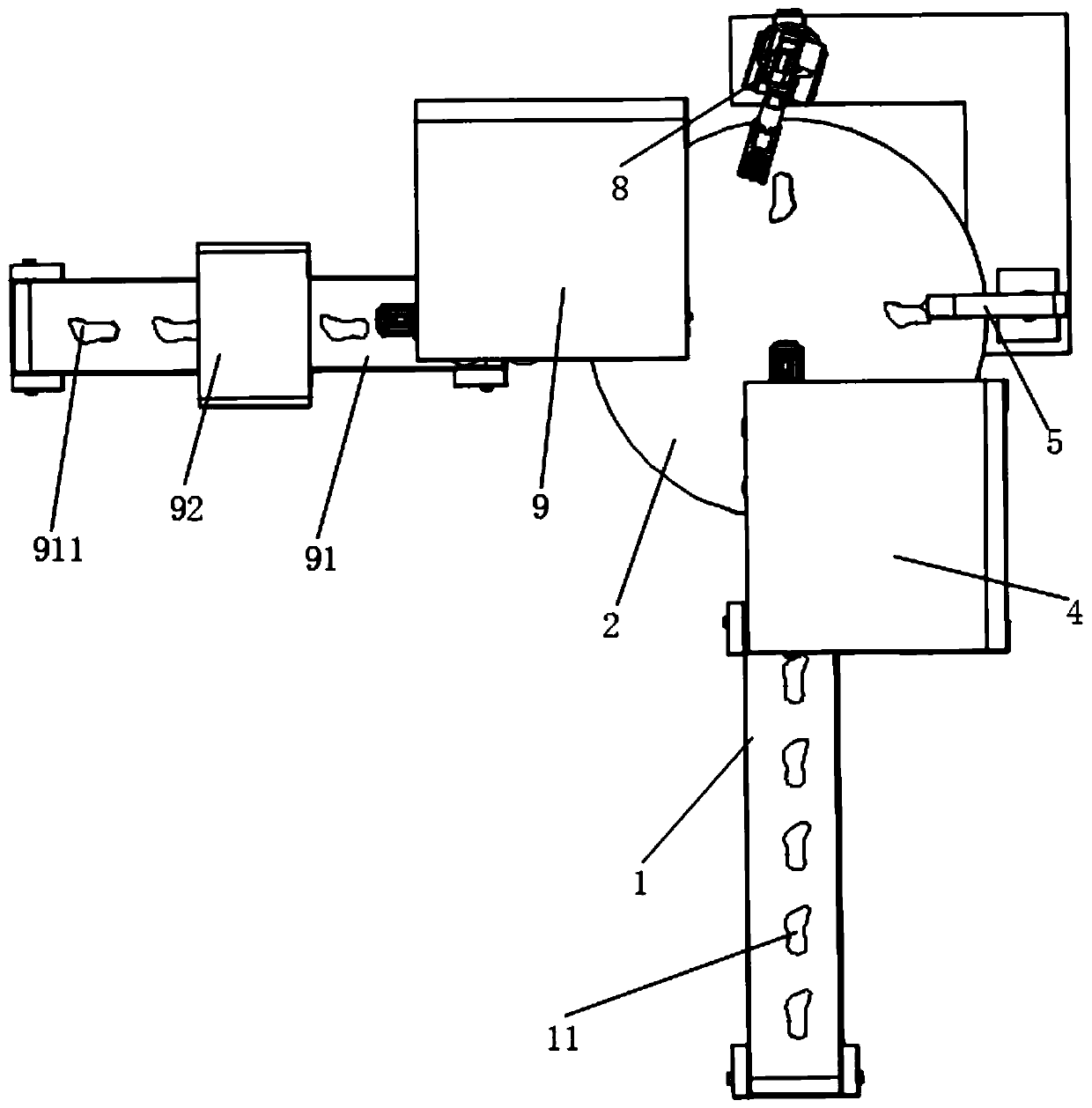

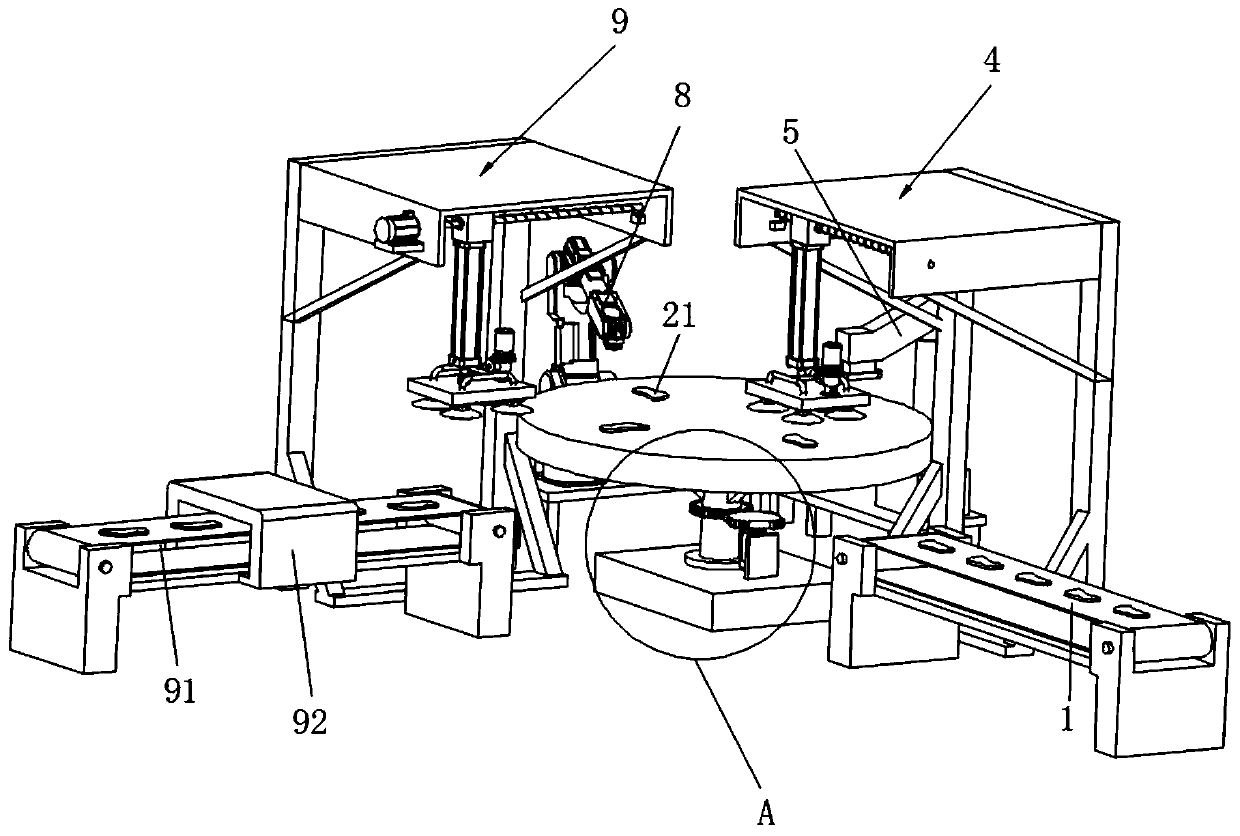

[0053] refer to figure 2 , 3 , a glue spraying system for shoe sole processing, used to complete loading, scanning, glue spraying, blanking and drying in sequence. In order to complete the above work, the system includes a first belt conveyor 1, a carrying device, a feeding device 4, trajectory generating device 5, glue spraying device 8, unloading device 9, second belt conveyor 91 and infrared drying box 92, it is worth noting that in this system, feeding device 4, trajectory generating device 5, The glue spraying device 8 and the unloading device 9 surround the carrying device to form a loading area, a scanning area, a glue spraying area, and a material unloading area. The following describes the system according to the workflow.

[0054] refer to figure 2 ,3 , the carrying device, including the carrying round table 2 and the first driving member 3, the carrying round table 2 is provided with four third placing grooves 21, and the four third placing grooves 21 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com