Over-crossing existing subway tunnel between-pile soil clearing method

A technology with existing subway and cleaning methods, applied to sheet pile walls, manual excavators/dredgers, construction, etc., can solve the problems of existing subway tunnels such as high danger, low work efficiency, and disturbance of isolated piles, etc., to achieve Short construction time, high safety, and the effect of reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

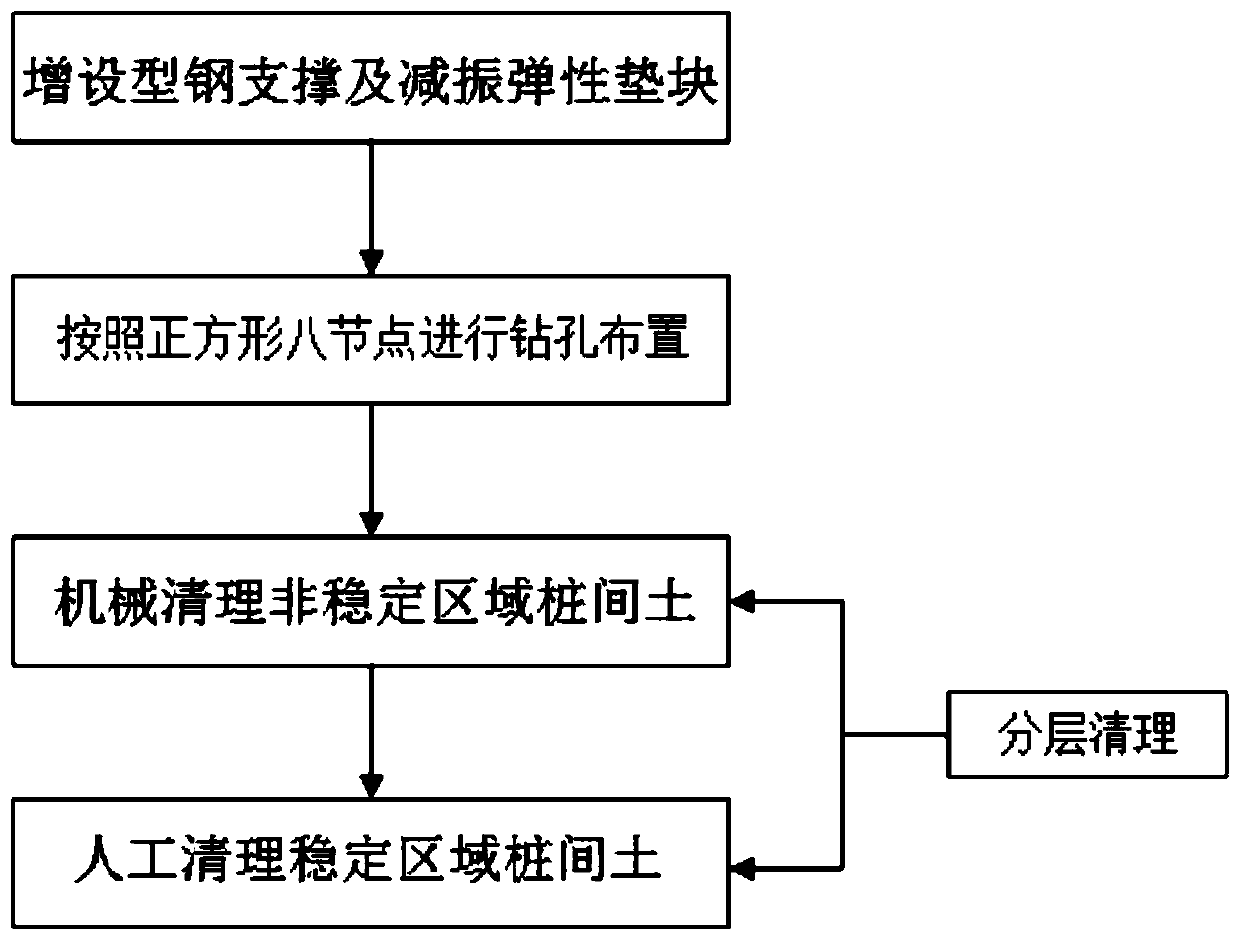

[0033] The cleaning equipment in the method for cleaning the soil between the existing subway tunnel piles on the upper span of the present invention includes a vibration damping elastic support, a jackhammer, a drill bit excavator and a backhoe excavator. The cleaning method specifically includes the following steps:

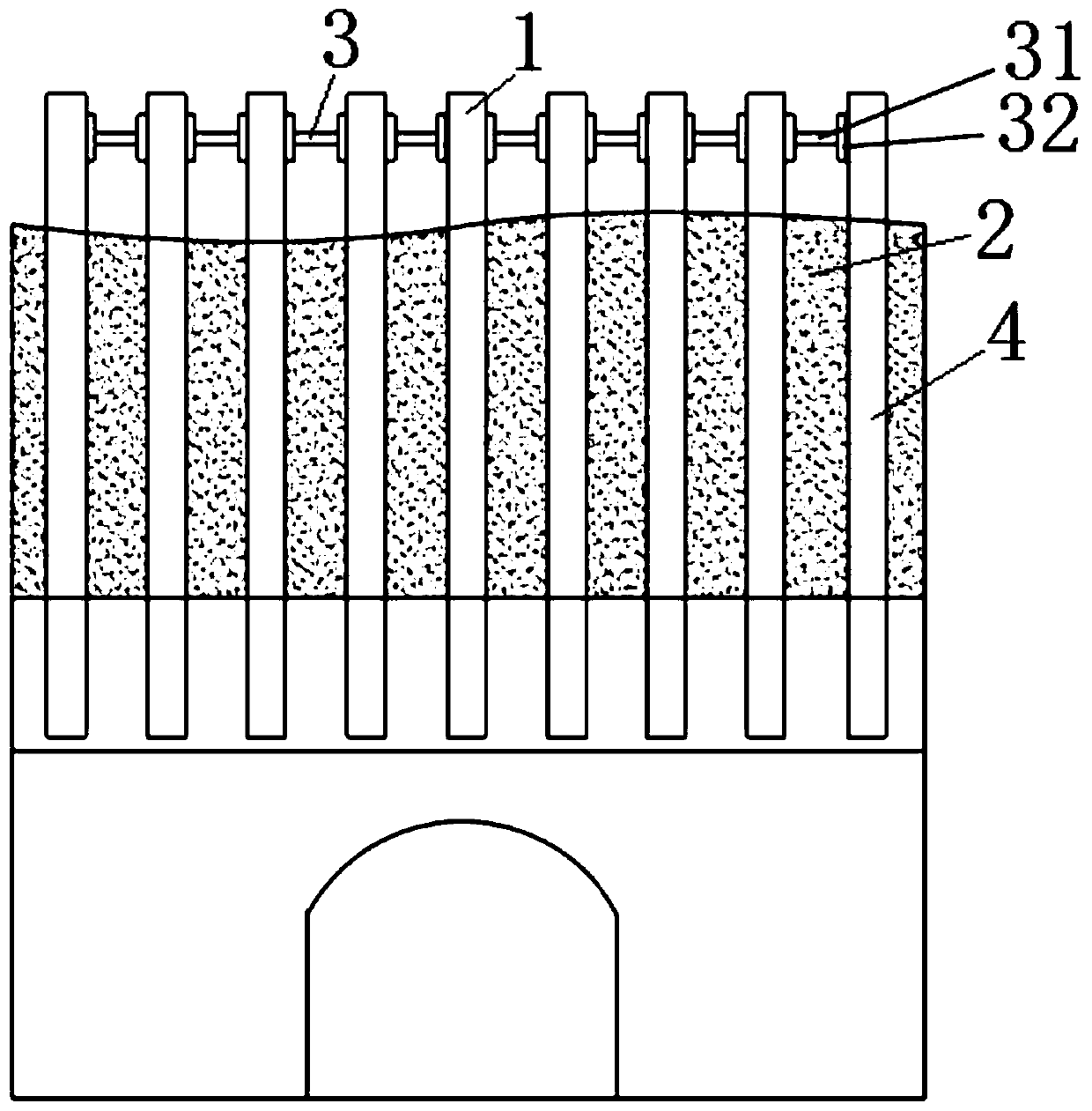

[0034]Step 1. Set up a vibration-damping elastic support 3 between two adjacent isolated piles 1. From the pile top of the isolated pile 1, set a vibration-damping elastic support 3 at intervals of 3-4m in the longitudinal direction. When the bottom of the isolated pile is less than 3m, A vibration-damping elastic support 3 needs to be added; two adjacent vibration-damping elastic supports 3 are set on the same horizontal line; each vibration-damping elastic support 3 includes a steel support 31 and two vibration-damping rubber pads 32, and the steel support 31 is set horizontally Between two adjacent isolation piles 1, two vibration-damping rubber pads 32 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com