Universal out-of-tank plating system for cylinder blocks

A general-purpose, cylinder technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of different fixtures, production line shutdown, manual replacement process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

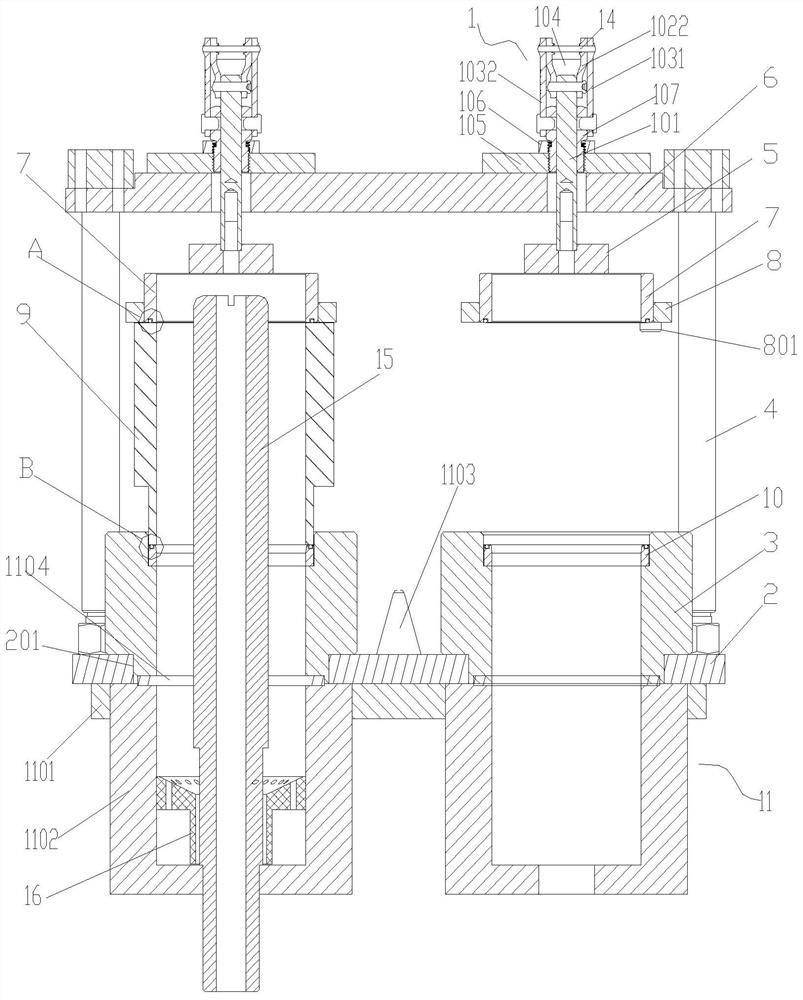

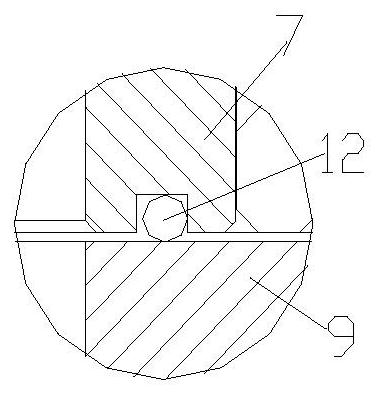

[0057] As shown in the figure: the general-purpose electroplating system outside the tank for the cylinder body of this embodiment,

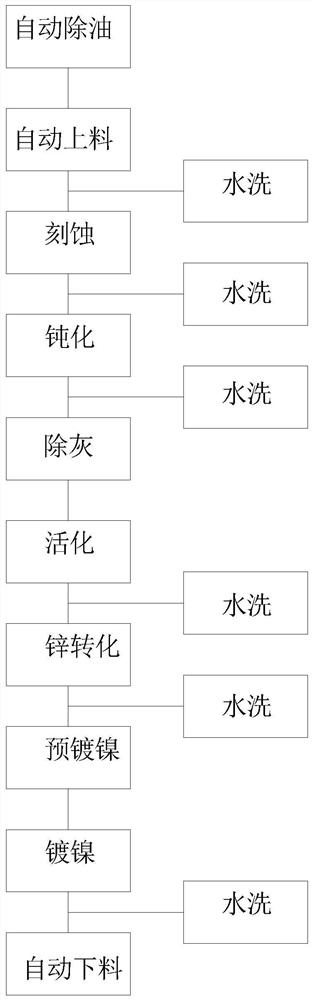

[0058] Including pre-plating treatment device, electroplating device and general-purpose tooling; pre-plating treatment device and electroplating device of the present invention, such as figure 1 As shown, the pre-plating treatment device includes etching, passivation, activation, and zinc conversion stations (there is also water washing in the middle, which will not be described here); of course, it also includes automatic degreasing, loading and unloading and other processes, which will not be repeated here. Repeat; the electroplating device generally includes pre-plating and plating processes, and the scope of protection required by the present invention is not limited to nickel plating, but includes all cyclic electroplating processes realized by the system of the present invention, and will not be repeated here;

[0059] The universal tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com