Photoelectric composite data bus and preparation method thereof

A data bus and photoelectric composite technology, which is applied in cable/conductor manufacturing, circuit, optics, etc., can solve the problems that the photoelectric signals of the bus cannot be transmitted at the same time, are not resistant to low temperature, and are not resistant to high temperature, and achieve good photoelectric transmission performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

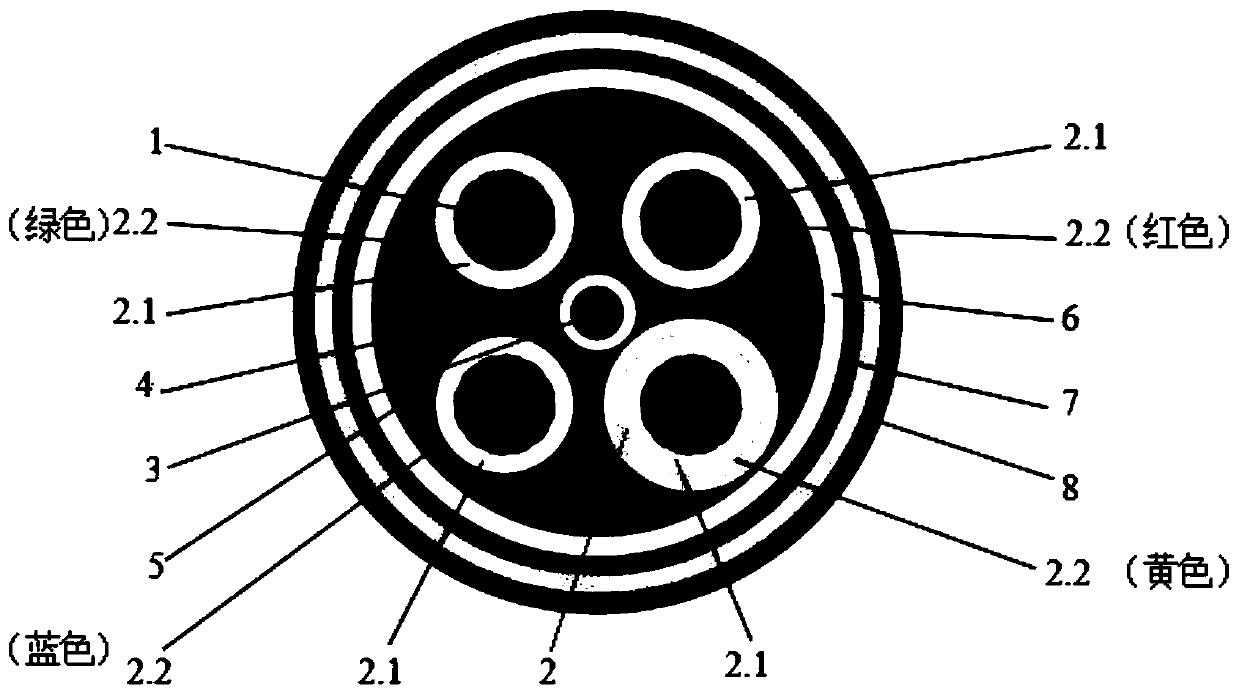

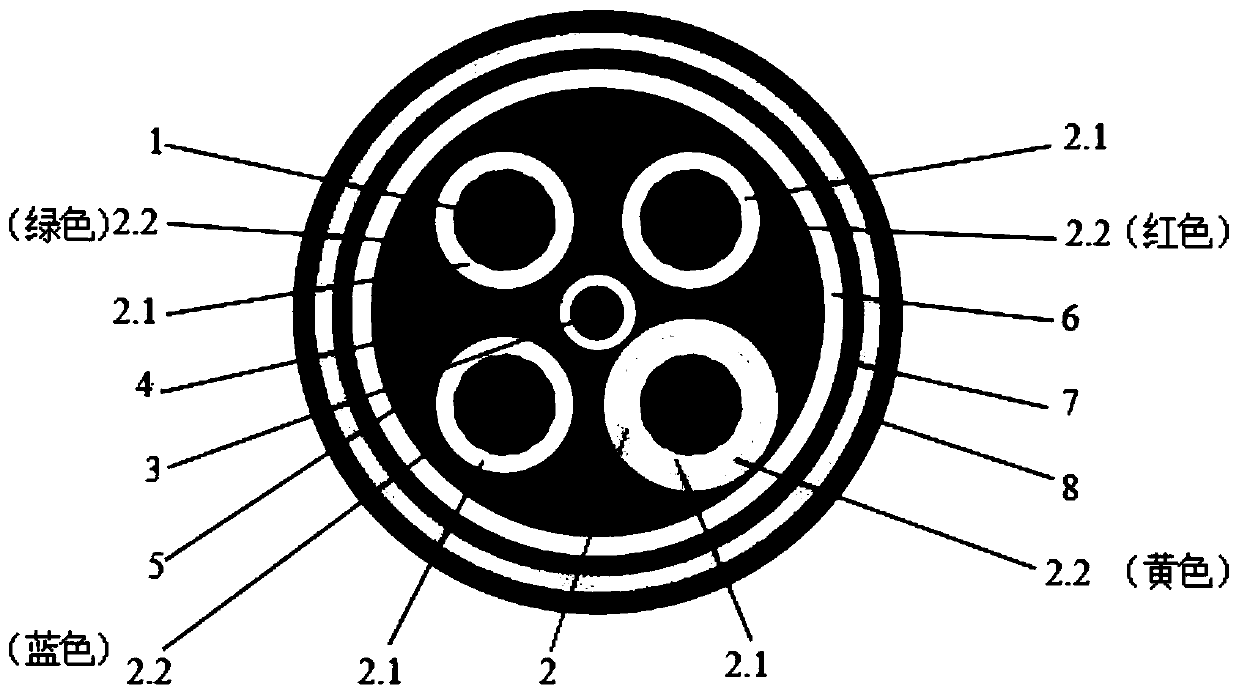

[0043] Embodiment 1, in conjunction with attached figure 1 describe.

[0044] An optoelectronic composite data bus, characterized in that it includes at least three silver-plated copper wire stranded conductors 1 and a single-mode optical fiber transmission carrier 3; the silver-plated copper wire stranded conductor 1 is wrapped with a first insulating layer 2; The single-mode optical fiber transmission carrier 3 is wrapped with a second insulating layer 4; the outer circumferential direction of the single-mode optical fiber transmission carrier 3 is stranded with the silver-plated copper wire stranded conductor 1 to form a photoelectric composite cable core 5; The photoelectric composite cable core 5 is wrapped with a fastening layer 6; the fastening layer 6 is provided with a shielding layer 7;

[0045] The optoelectronic composite data bus of this embodiment uses three silver-plated copper wire stranded conductors for electrical signal transmission and a single-mode optica...

Embodiment 2

[0051] Embodiment 2, in conjunction with attached figure 1 describe.

[0052] For further clarifying the technical effect of the photoelectric composite data bus of the present invention, a kind of method for preparing the product of embodiment 1 is provided:

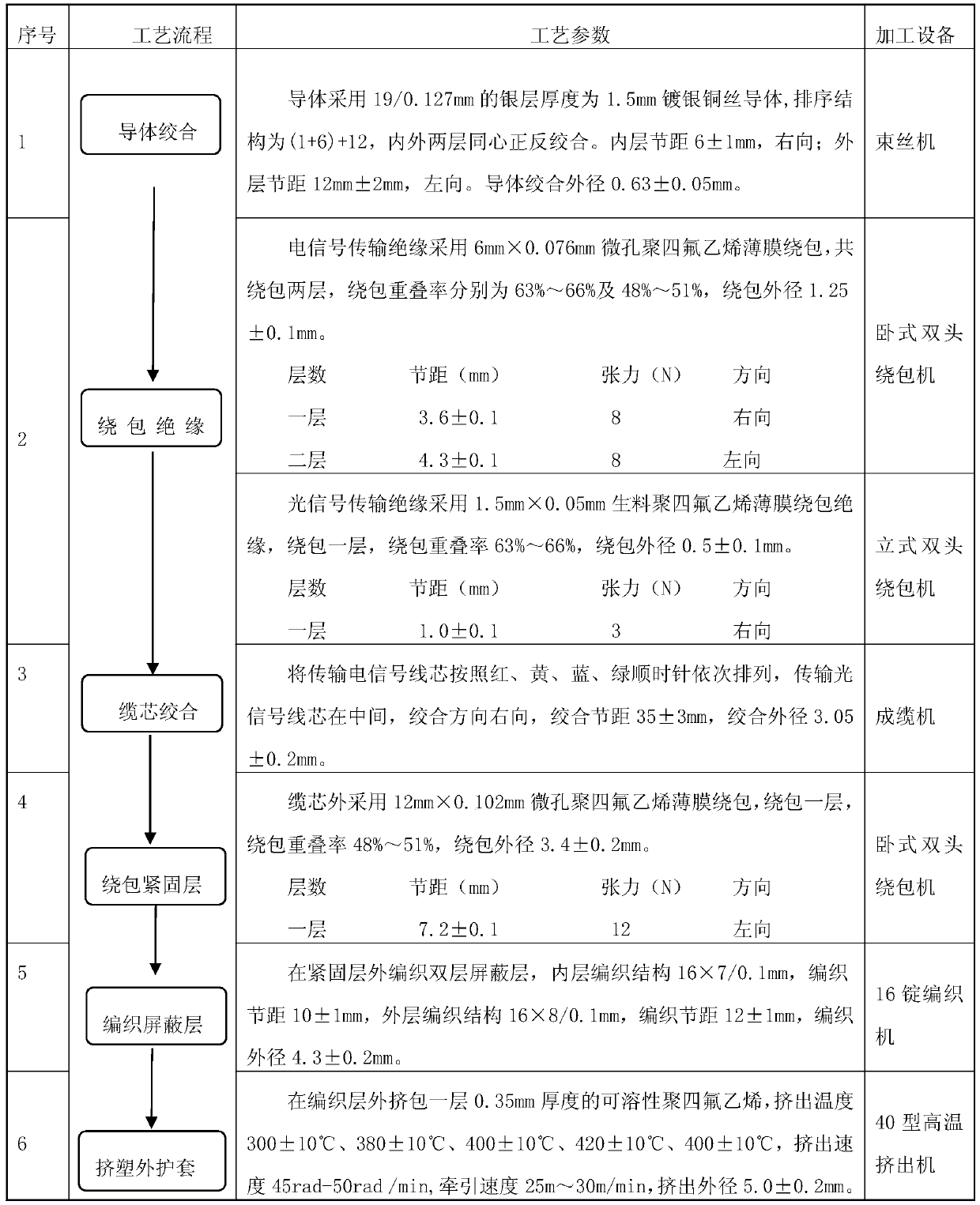

[0053] A preparation method for an optoelectronic composite data bus, specifically comprising the steps of:

[0054] Step 1. Preparation of silver-plated copper wire stranded conductor 1: Arrange single conductors in sequence from the inside to the outside with a bundle machine, and twist out the silver-plated copper wire conductors from the inside to the outside in forward and reverse directions;

[0055] Step 2. Wrapping the first insulating layer 2: Wrap the silver-plated copper wire stranded conductor 1 with a microporous polytetrafluoroethylene film with a width of 6mm x a thickness of 0.076mm by a horizontal double-headed wrapping machine, and wrap two layers in total to form first insulating layer 2;

[0056] ...

Embodiment 3

[0070] Embodiment 3, in conjunction with attached figure 1 describe.

[0071] For further clarifying the technical effect of the photoelectric composite data bus of the present invention, a kind of method for preparing the product of embodiment 1 is provided:

[0072] A preparation method for an optoelectronic composite data bus, specifically comprising the steps of:

[0073] Step 1. Preparation of silver-plated copper wire stranded conductor 1: Arrange single conductors in sequence from the inside to the outside with a bundle machine, and twist out the silver-plated copper wire conductors from the inside to the outside in forward and reverse directions;

[0074] Step 2. Wrapping the first insulating layer 2: Wrap the silver-plated copper wire stranded conductor 1 with a microporous polytetrafluoroethylene film with a width of 6mm x a thickness of 0.076mm by a horizontal double-headed wrapping machine, and wrap two layers in total to form first insulating layer 2;

[0075] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com