Galvanic corrosion evaluation method for dissimilar metal plate mechanical connection structure in automobile

A mechanical connection structure and galvanic corrosion technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, material analysis, and weighing by removing certain components, can solve the problem of inability to conveniently and comprehensively reflect the mechanical connection of dissimilar metal plates Corrosion in the contact area of structural materials and other issues, to achieve the effect of controlling the risk of galvanic corrosion and production costs, good correlation, and easy accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for evaluating galvanic corrosion of a mechanical connection structure of dissimilar metal sheets in an automobile, comprising the following steps:

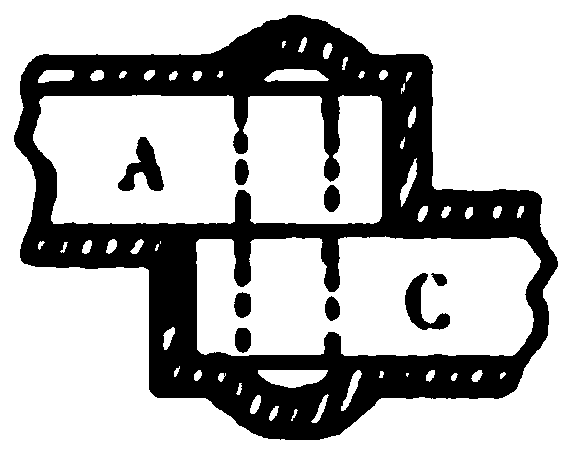

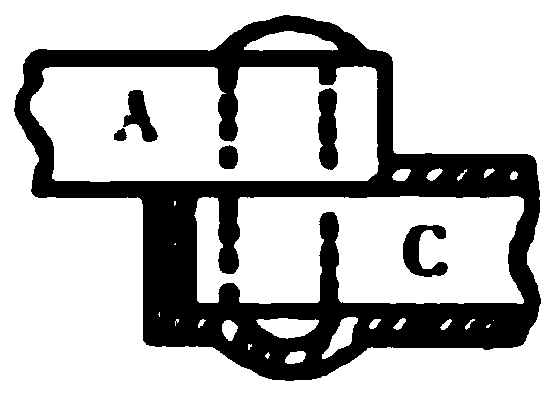

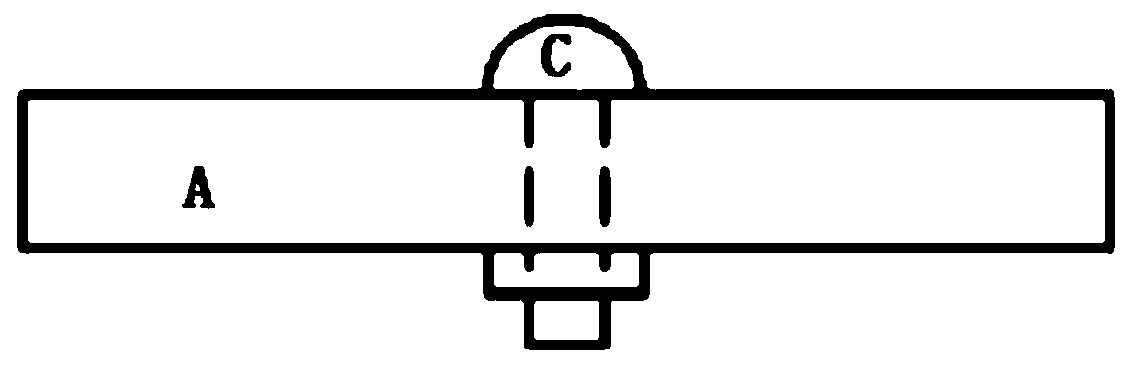

[0038] (1) There are two groups of sheet materials for the mechanical connection structure of automobile dissimilar metal sheets that need to be evaluated for galvanic corrosion. The sheets in one group are 6014 aluminum sheet and trivalent color zinc plate (base steel material), and the other group is The medium plate is 6014 aluminum plate and zinc-nickel coated plate (base steel material). According to the electrode potential sequence in the galvanic test of the two different plate materials, the 6014 aluminum plate is determined as the anodic plate. The production is made of 6014 aluminum plate and trivalent plated Connection test pieces composed of color zinc bolts and trivalent color zinc plated nuts (see image 3 ), and a connection test piece composed of 6014 aluminum plate, zinc-nickel coated bolts, and z...

Embodiment 2

[0049] A method for evaluating galvanic corrosion of a mechanical connection structure of dissimilar metal sheets in an automobile, comprising the following steps:

[0050] (1) There are two groups of sheet materials for the mechanical connection structure of automobile dissimilar metal sheets that need to be evaluated for galvanic corrosion. The sheets in one group are 6014 aluminum sheet and yellow galvanized sheet (base steel material), and the sheets in the other group They are 6014 aluminum plate and black Dacromet coated plate (base steel material). According to the electrode potential sequence in the galvanic test of two different plate materials, 6014 aluminum plate is determined as anodic plate. The connection test piece consisting of zinc bolts and yellow zinc-plated nuts, and the connection test piece composed of 6014 aluminum plate and black dacromet-coated bolts and black dacromet-coated nuts were used for galvanic corrosion evaluation.

[0051] (2) First of all, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com