Quick dredging equipment for blockage of 3D printer spraying head

A 3D printer and nozzle technology, applied in the field of 3D printing, can solve the problems of inconvenient manual cleaning and residual materials affecting the next operation, and achieve the effect of solving the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

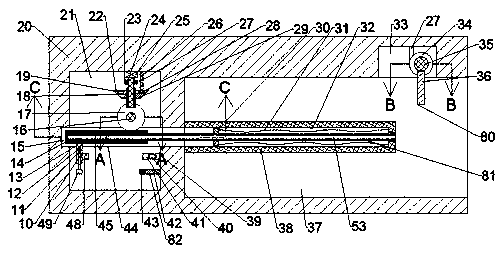

[0019] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

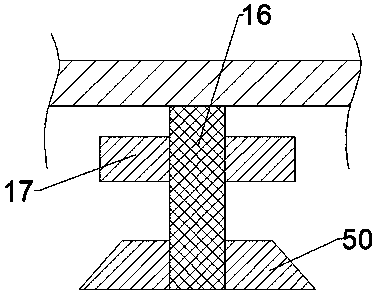

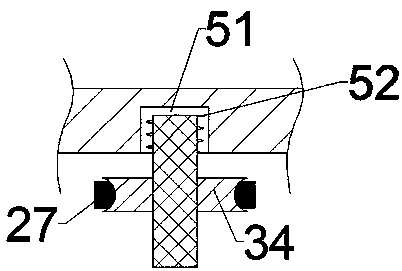

[0020] A 3D printer nozzle clogging fast dredging device described in conjunction with accompanying drawings 1-5 includes a cleaning pen 20, the right end of the cleaning pen 20 is provided with a working chamber 37 that opens to the right, and the upper end wall of the working chamber 37 is provided with The rotating chamber 33 with the opening downward, the working chamber 37 is provided with a detection mechanism 80, the detection mechanism 80 includes a torsion spring groove 51 arranged on the rear end wall of the rotation chamber 33, and the torsion spring groove 51 is formed from A winding wheel 34 and a rotating rod 36 are fixed to the front one time, a torsion spring 52 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com