Novel pin insulator

A pin insulator, a new type of technology, applied in the field of new pin insulators, can solve the problems of low safety, cumbersome installation, and long stay time of installers, so as to simplify the connection operation, improve safety, and reduce the risk of being left alone The effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

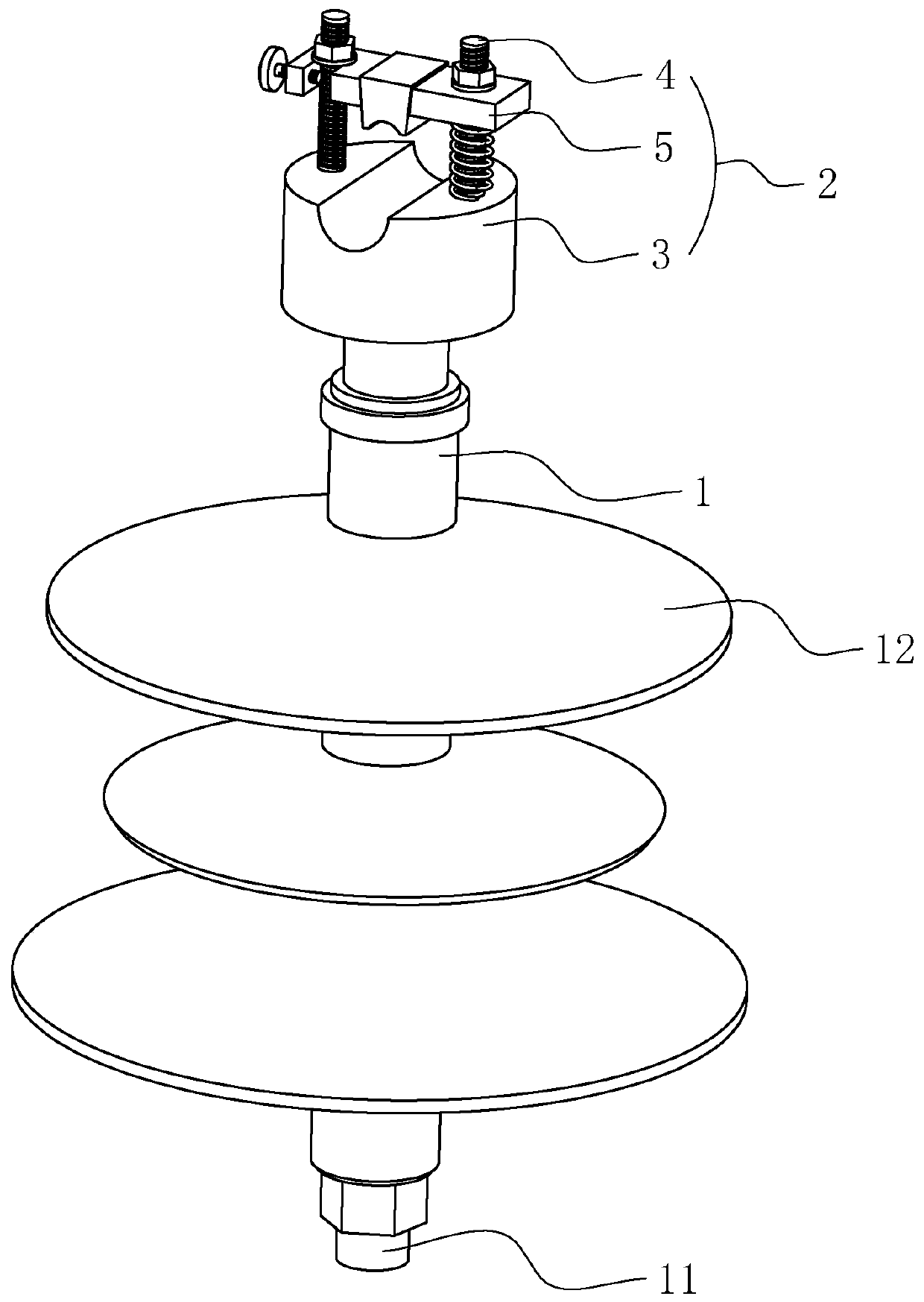

[0053] refer to figure 1 with figure 2 , is a new type of pin insulator disclosed in this embodiment, including an insulating pin body 1, the two ends of the insulating pin body 1 are respectively installed with a connecting part 11 and a mounting part 2, the connecting part 11 is used to connect with the utility pole, and the insulating pin Several umbrella covers 12 are fixed on the periphery of the body 1 .

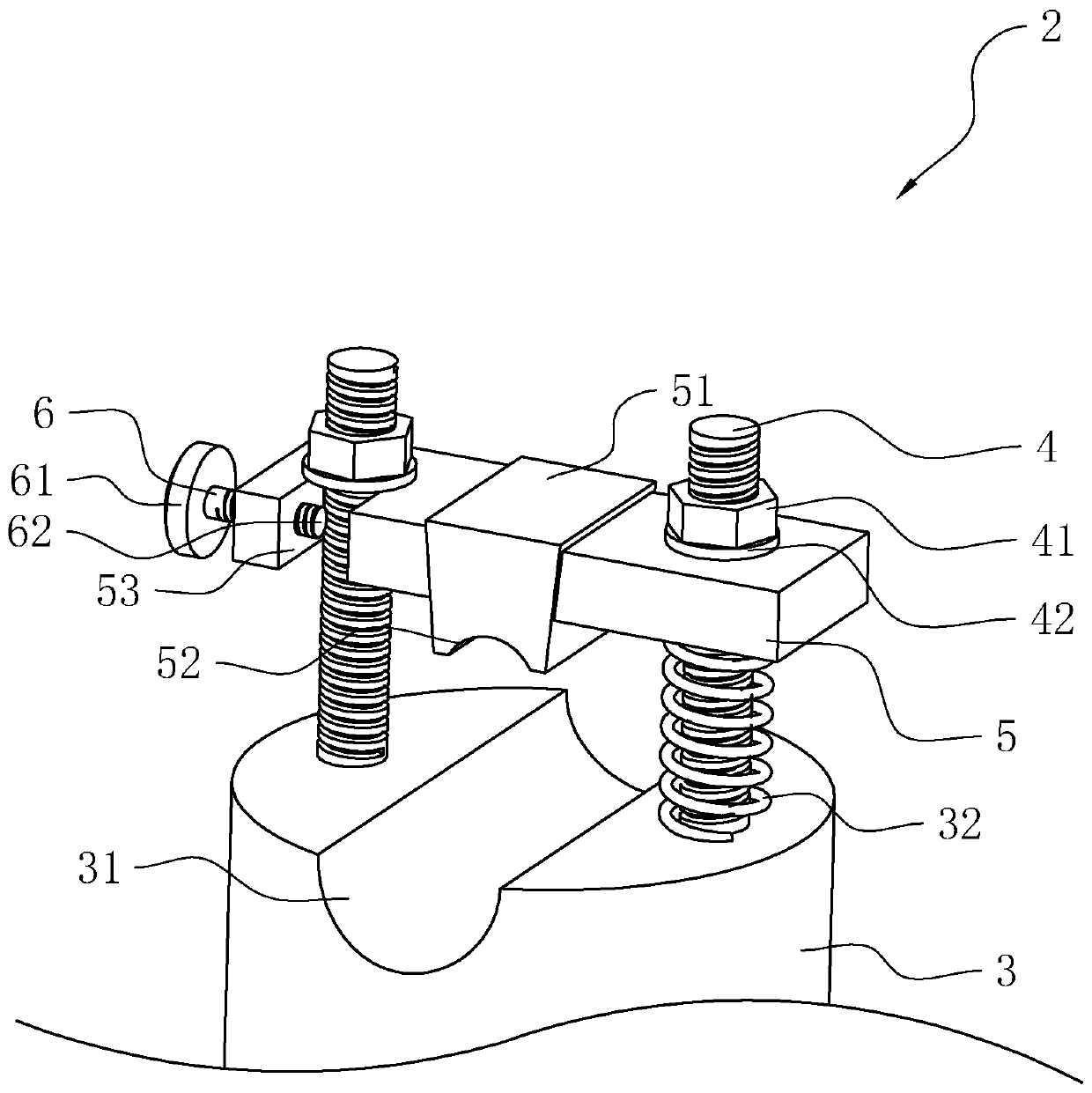

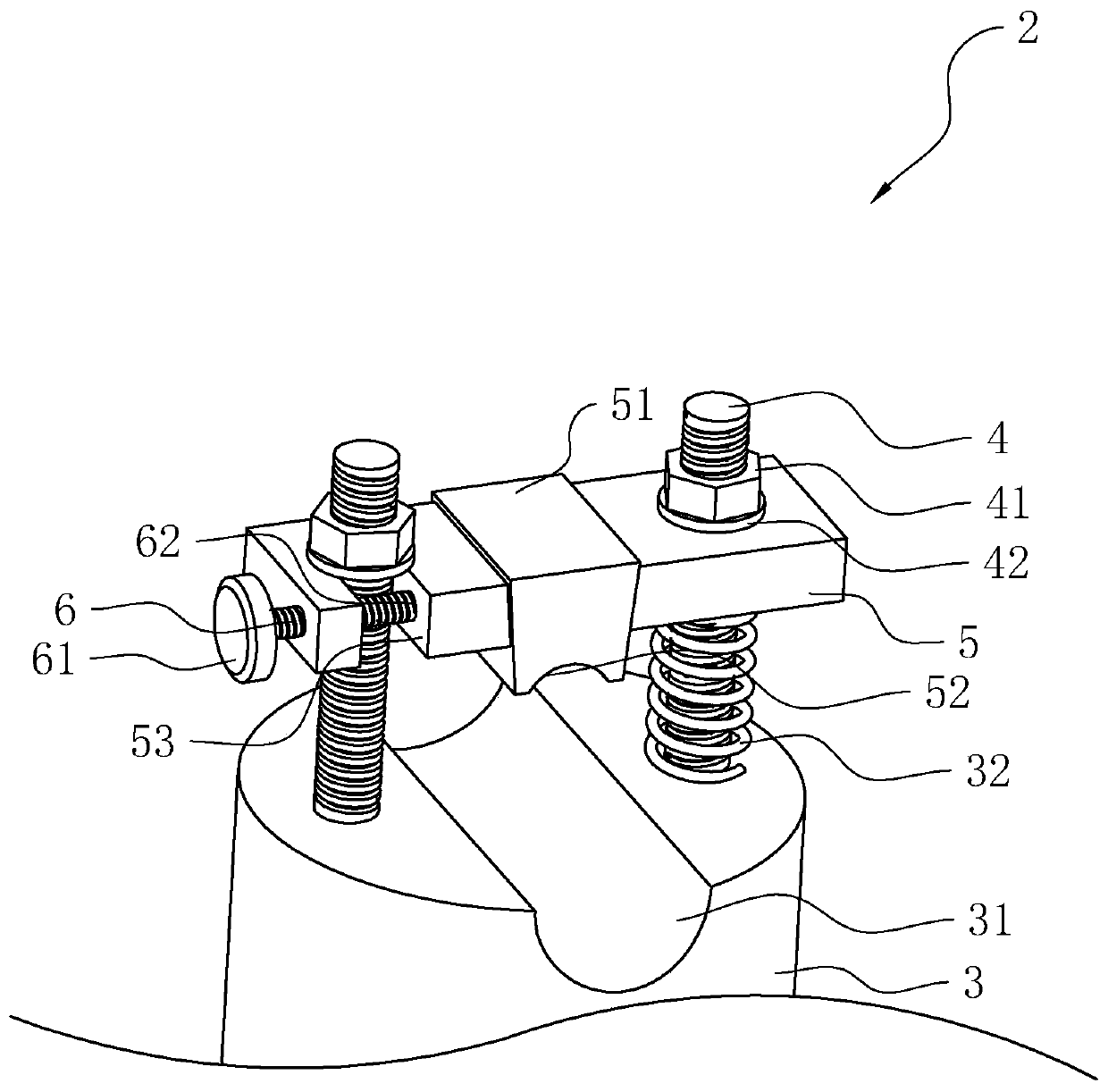

[0054] The mounting part 2 includes a mounting base 3, two threaded columns 4, and a clamping block 5. The side of the mounting base 3 away from the insulating needle body 1 is the upper surface of the mounting base 3, and the upper surface of the mounting base 3 is recessed with a mounting groove 31. , the mounting groove 31 is used to place the wires; two threaded columns 4 are arranged in parallel and fixed on the upper surface of the mounting seat 3, the mounting groove 31 is sandwiched between the two threaded columns 4; the clamping block 5 is connected to the ...

Embodiment 2

[0065] refer to image 3 , is a new type of pin insulator disclosed in this embodiment. The difference between this embodiment and Embodiment 1 is that the tail end 62 of the limiting member 6 penetrates into the groove wall of the clamping groove 53 to close the clamping groove. 53, and cooperate with the clamping groove 53 to form a closed ring-shaped restricted area.

[0066] The implementation principle of this embodiment is the same as that of Embodiment 1; where it is worth noting that, since the tail end 62 of the limiting member 6 penetrates into the groove wall of the clamping groove 53, the supporting point of the entire limiting member 6 There are two places. In the high-altitude and strong wind environment, the limiting member 6 is less likely to break, deform and other problems.

Embodiment 3

[0068] refer to Figure 4 , is a new type of pin insulator disclosed in this embodiment. The only difference between this embodiment and Embodiment 2 is that the limiting member 6 sequentially includes a large-diameter section 63, a transition section 64, and a small-diameter section 65 along its length direction. Portion 61 is located at the end of large-diameter section 63, and tail end 62 is located at the end of small-diameter section 65, and the external diameter of large-diameter section 63 is greater than the external diameter of small-diameter section 65, and the external diameter of transition section 64 is changed by large-diameter section 63 The direction to the small-diameter section 65 is gradually reduced; the threaded post 4 abuts against the bottom of the locking groove 53 , and the outer peripheral wall of the threaded post 4 abuts against the transition section 64 .

[0069] The implementation principle of this embodiment is: this embodiment is an improved so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com