A kind of antibacterial nano-ion water-based coating liquid, preparation method of water-based coating liquid and antibacterial material using the water-based coating liquid

A technology of bacteriostatic materials and nano-ions is applied in the field of bacteriostatic nano-ionic water-based coating liquid, anti-bacterial materials and preparation, and preparation of water-based coating liquid, which can solve the problem of affecting the appearance of white or light-colored products, reducing physical properties, using The problem of high cost is to prevent the spread of bacterial contamination, achieve excellent bacteriostatic effect, and solve the effect of pollution burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

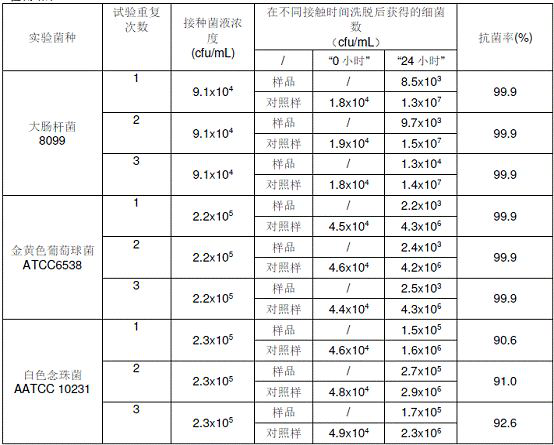

Examples

Embodiment 1

[0027] Embodiment 1: a kind of preparation method of antibacterial nano-ionic water-based coating liquid, it comprises the following steps:

[0028] (1) Preparation of nano-zinc oxide and nano-titanium oxide aqueous dispersion;

[0029] (2) Deionized water and isopropanol are prepared into a diluent in a volume ratio of 1:5;

[0030] (3) Prepare water-based polyurethane resin liquid;

[0031] (4) adding the nano-zinc oxide and nano-titanium oxide aqueous dispersion obtained in step (1) to the diluent obtained in step (2) with a volume of 4 times, and stirring at room temperature until uniform to obtain mixed solution 1;

[0032] (5) Add the water-based polyurethane resin solution to the mixed solution 1 obtained in step (4) by 4 times the volume, and fully stir to obtain the mixed solution 2;

[0033] (6) Add the organosiloxane leveling agent, the wetting agent polyethylene glycol, and the slipping aid polyether-modified polysiloxane into the mixed solution 2 in turn and sti...

Embodiment 2

[0036] Embodiment 2: a kind of preparation method of antibacterial nano-ionic water-based coating liquid, it comprises the following steps:

[0037] (1) Preparation of nano-zinc oxide and nano-titanium oxide aqueous dispersion;

[0038] (2) Deionized water and isopropanol are prepared into a diluent in a volume ratio of 1:1;

[0039] (3) Prepare water-based polyurethane resin liquid;

[0040] (4) adding the nano-zinc oxide and nano-titanium oxide aqueous dispersion obtained in step (1) to the diluent obtained in step (2) with a volume of 6 times, and stirring at room temperature until uniform to obtain mixed solution 1;

[0041] (5) Add the water-based polyurethane resin solution to the mixed solution 1 obtained in step (4) with a volume of 5 times, and fully stir to obtain the mixed solution 2;

[0042] (6) Add acrylate leveling agent, sodium dodecyl sulfonate and polydimethylsiloxane into mixed solution 2 and stir evenly to prepare antibacterial nano-ionic water-based coat...

Embodiment 3

[0045] Embodiment 3: a kind of preparation method of antibacterial nano-ionic water-based coating liquid, it comprises the following steps:

[0046] (1) Preparation of nano-zinc oxide and nano-titanium oxide aqueous dispersion;

[0047] (2) Deionized water and isopropanol are prepared into a diluent in a volume ratio of 1:10;

[0048] (3) Prepare water-based polyurethane resin liquid;

[0049] (4) adding the nano-zinc oxide and nano-titanium oxide aqueous dispersion obtained in step (1) to the diluent obtained in step (2) with twice the volume, and stirring at room temperature until uniform to obtain mixed solution 1;

[0050] (5) Add the water-based polyurethane resin solution to the mixed solution 1 obtained in step (4) by 3 times the volume, and fully stir to obtain the mixed solution 2;

[0051] (6) Add the acrylic leveling agent, sodium lauryl sulfate, and polymer silicone to the mixed solution 2 and stir evenly to obtain the antibacterial nanoionic water-based coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com