ABC dry powder extinguishing agent and preparation method thereof

A technology of dry powder fire extinguishing agent and mica powder, which is applied in fire prevention equipment, etc., can solve the problems of fire extinguishing agent performance degradation, short storage time, and high production cost, and achieve the effects of reducing moisture absorption rate, low production cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

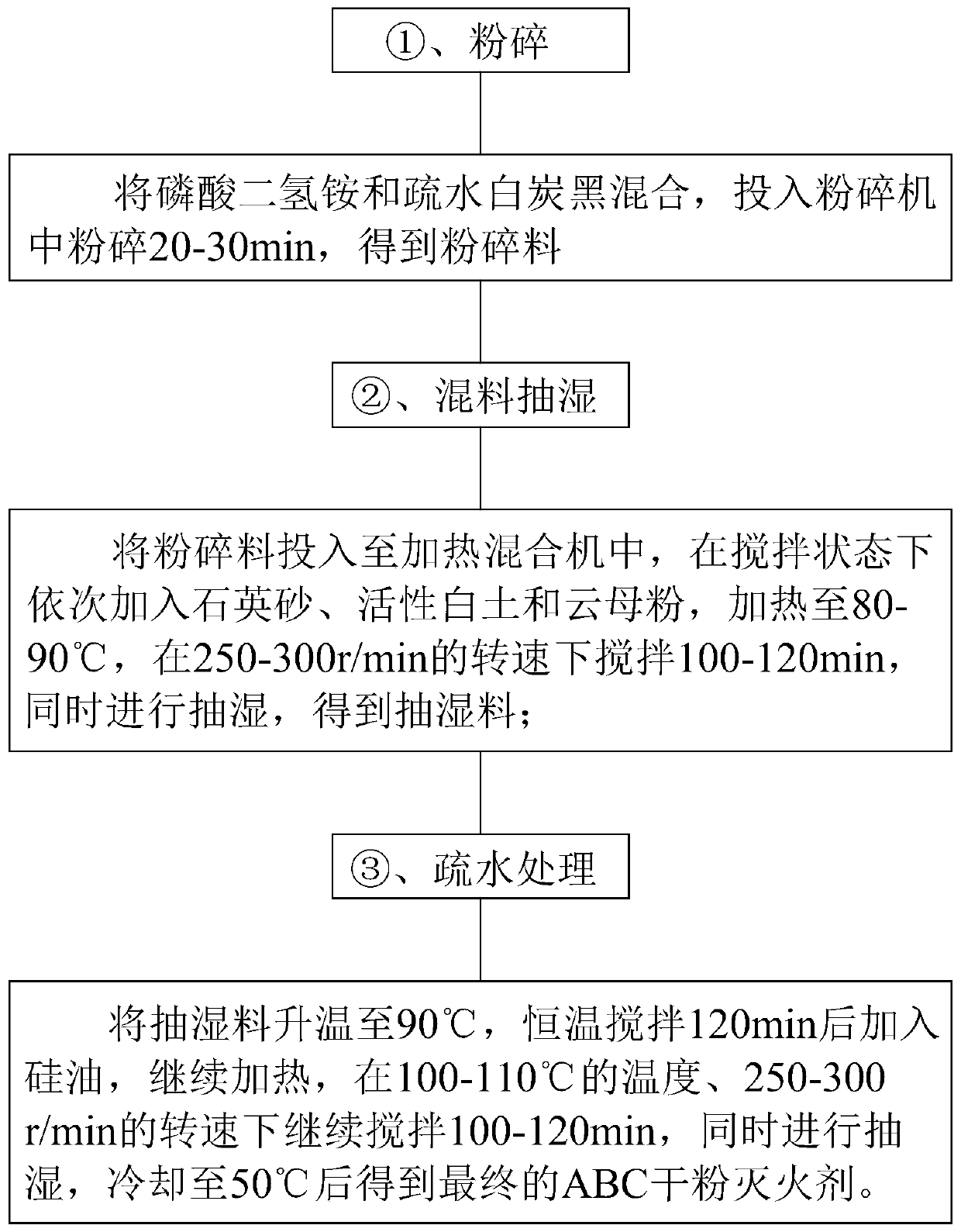

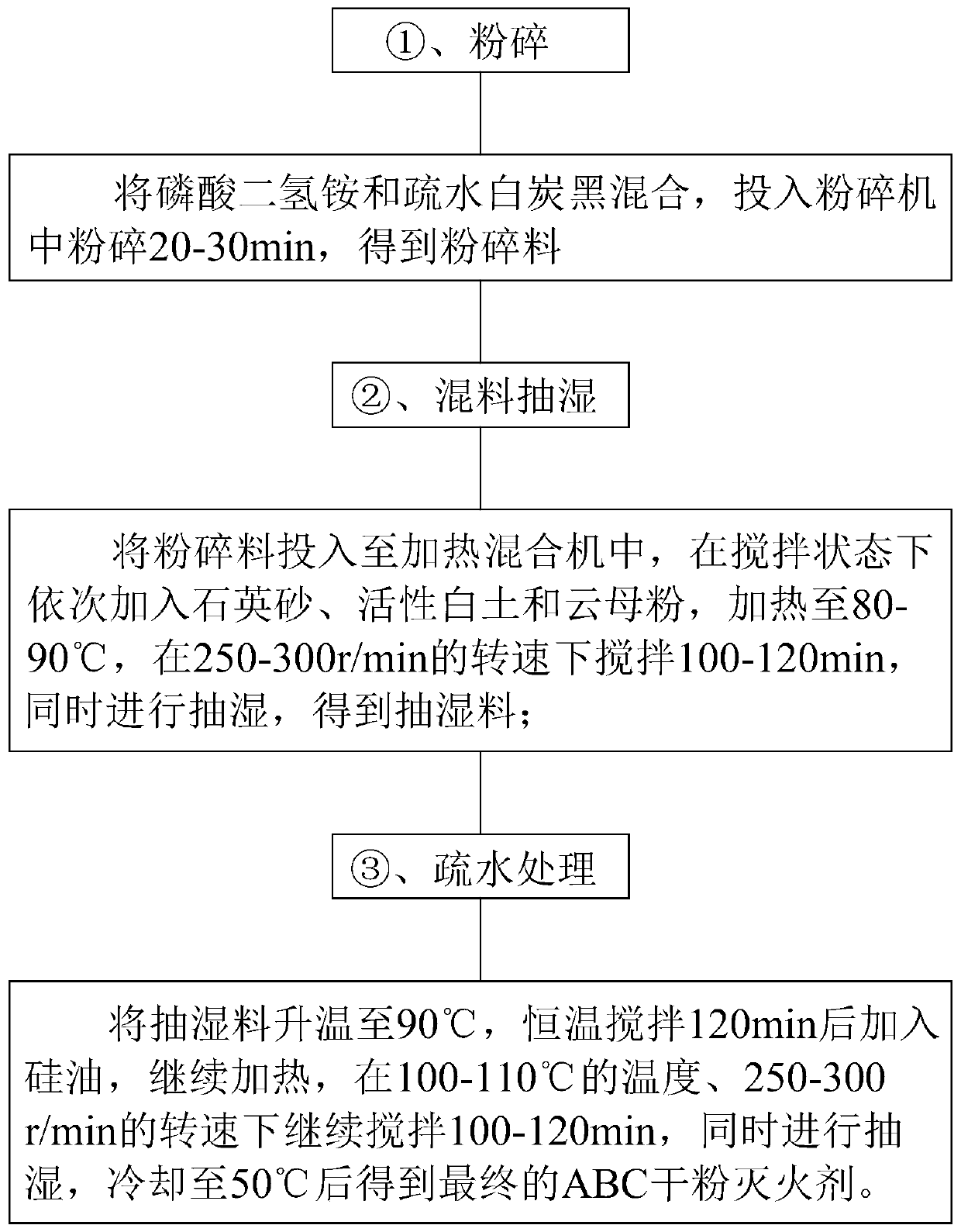

Method used

Image

Examples

Embodiment 2-4

[0062] Embodiments 2-4 are all based on the method of Embodiment 1, and the components and the number of parts of the ABC dry powder fire extinguishing agent are adjusted, and the specific adjustments are shown in Table 1 below.

[0063] Table 1 The component distribution table of the ABC dry powder fire extinguishing agent of embodiment 1-4

[0064] Example 1 Example 2 Example 3 Example 4 Ammonium dihydrogen phosphate 80 77 82 80 Quartz sand (40-250μm) 15 12 10 15 activated clay 1.5 3.0 1.0 1.5 Hydrophobic silica 1.8 1.8 1.0 3.0 Mica powder 1.0 2.0 2.0 1.0 silicone oil 0.7 1.0 0.5 0.5

Embodiment 5

[0066] Example 5 On the basis of the method in Example 1, the 40-250 μm quartz sand is changed to 2-30 μm quartz sand.

[0067] 2.4, Embodiment 6

Embodiment 6

[0068] Example 6 On the basis of the method in Example 1, the 40-250 μm quartz sand is changed to 270-400 μm quartz sand.

[0069] 2.5. Examples 7-11

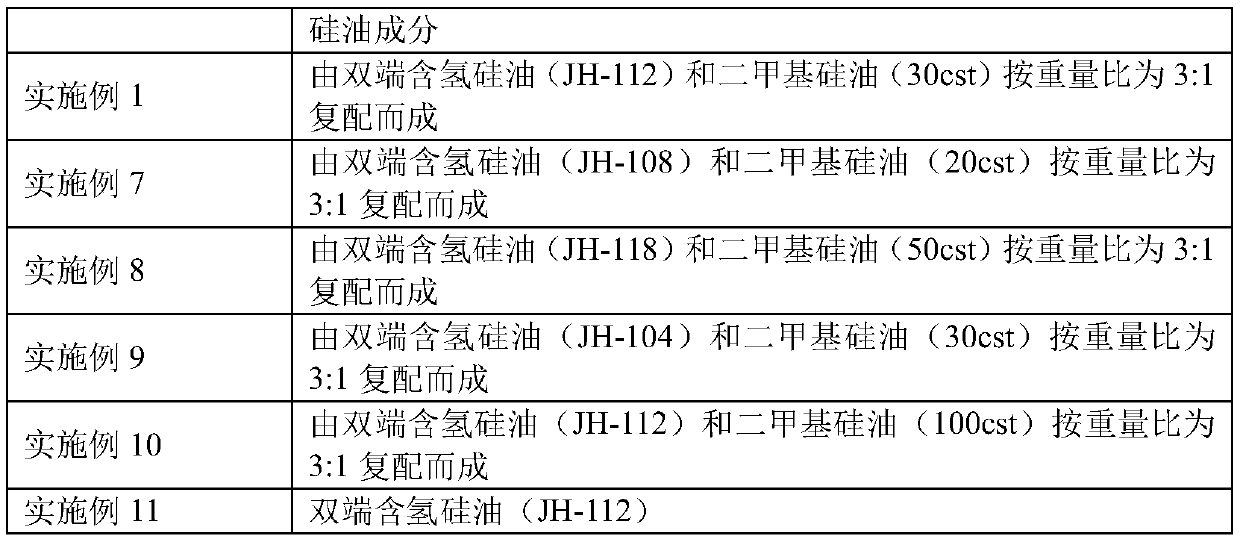

[0070] Examples 7-11 On the basis of the method in Example 1, the composition of the silicone oil was adjusted, and the specific adjustments are shown in Table 2 below.

[0071] Table 2 The silicone oil composition ratio table of embodiment 1 and embodiment 6-11

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com