Hot and sour rice noodle sauce and preparation method thereof

A hot and sour powder and sauce technology, which is applied in the food field, can solve problems such as stratification, precipitation at the bottom of the hot and sour powder, and affecting the flavor of the hot and sour powder, and achieve the effect of simple process, convenient operation and improved liking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

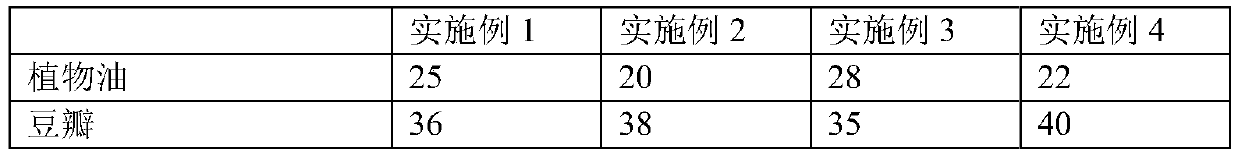

[0044] A hot and sour powder sauce, comprising the following components by weight: 25 parts of vegetable oil, 36 parts of watercress, 10 parts of minced garlic, 6 parts of chili powder, 4 parts of spice powder, 5 parts of Chinese prickly ash, 10 parts of soy sauce, and 2 parts of cornstarch , 2 parts of salt, 3 parts of monosodium glutamate.

[0045] Among them, vegetable oil is prepared from soybean oil, olive oil, and peanut oil in a weight ratio of 3:1:2; soy sauce is brewed soy sauce, and its amino acid nitrogen content is 0.60g / mL; oil-absorbing corn starch is B730 modified corn starch , the number of mesh is 900 mesh.

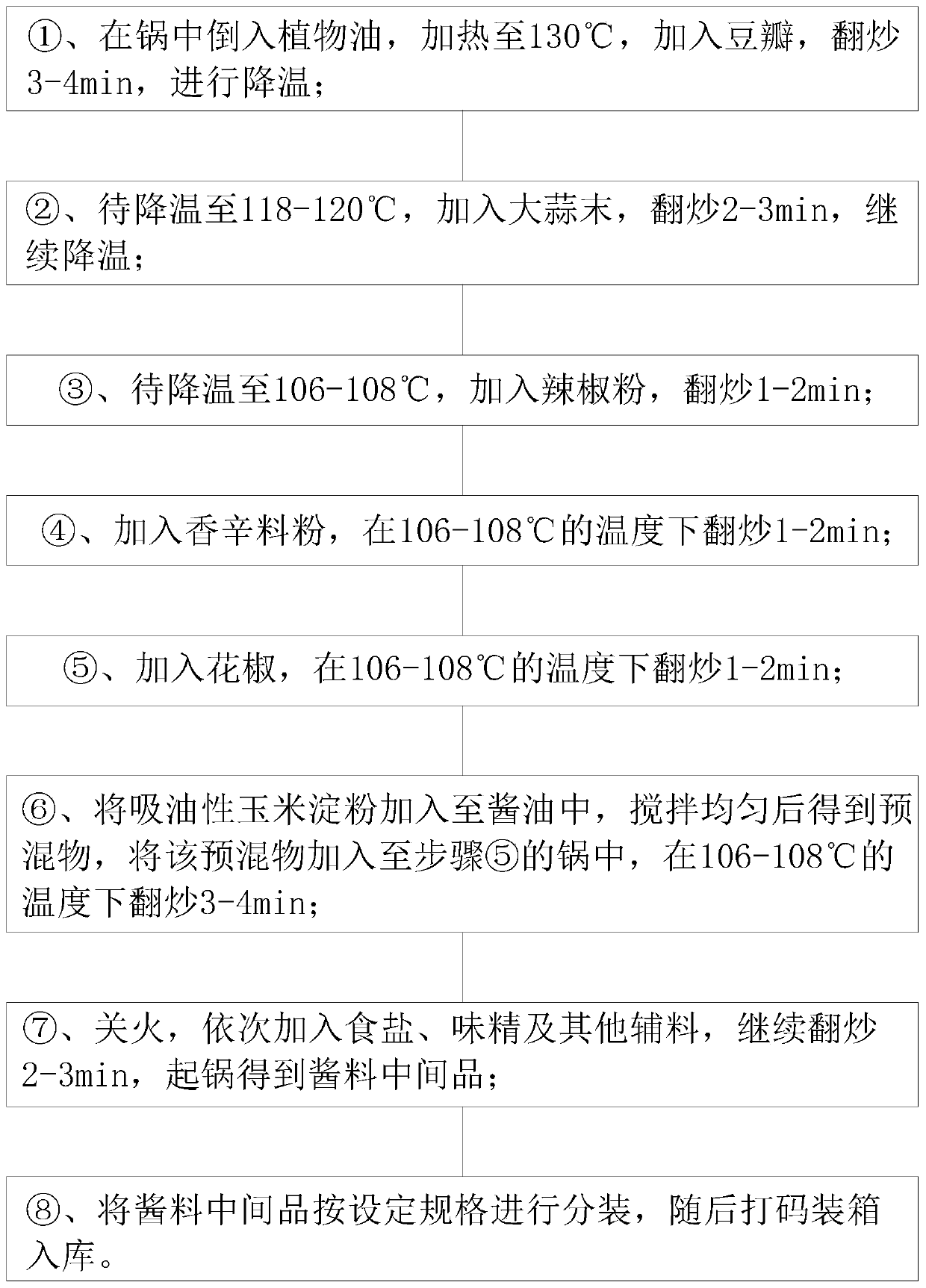

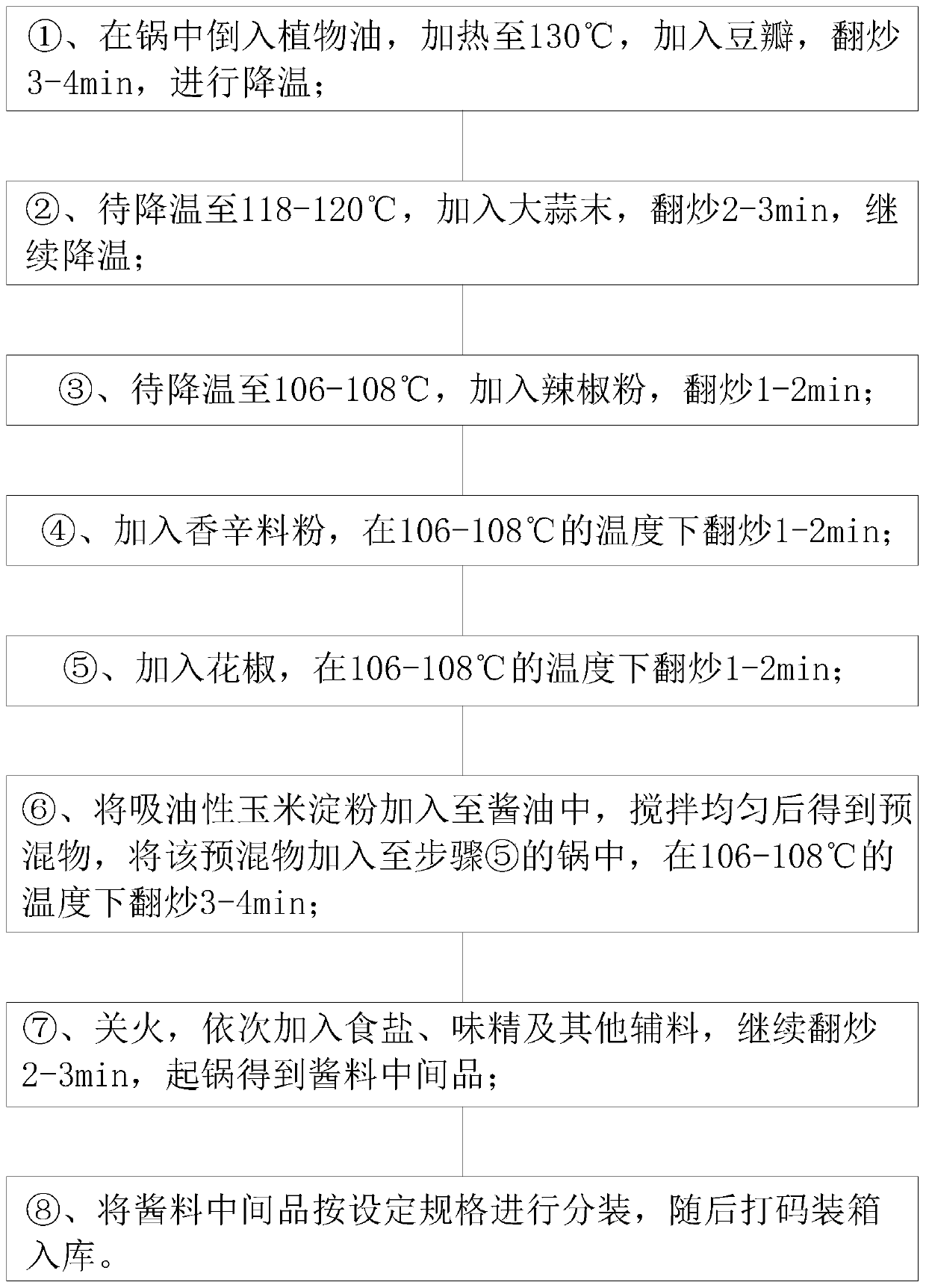

[0046] The preparation method of above-mentioned hot and sour powder sauce material, see figure 1 , including the following steps:

[0047] ①. Pour vegetable oil into the pot, heat to 130°C, lubricate the pot wall with vegetable oil, then slide the watercress into the vegetable oil along the pot wall, stir fry for 3 minutes, and cool down;

[0048] ② W...

Embodiment 5

[0061] Embodiments 5-6 are all based on the method of Embodiment 1, and the vegetable oil is adjusted. Wherein, the vegetable oil of embodiment 5 is that soybean oil and olive oil are formulated by the weight ratio of 1:1; The vegetable oil of embodiment 6 is that soybean oil, olive oil and sesame oil are formulated by the weight ratio of 3:1:2 .

[0062] 1.4. Examples 7-10

Embodiment 7

[0063] Embodiment 7-10 is all on the method basis of embodiment 1, adjusts soy sauce. Wherein, the amino acid nitrogen content of soy sauce in Example 7 is 0.55 g / mL; the amino acid nitrogen content of soy sauce in Example 8 is 0.65 g / mL; the amino acid nitrogen content of soy sauce in Example 9 is 0.70 g / mL; The soy sauce in Example 10 is formulated soy sauce, and its amino acid nitrogen content is 0.40 g / mL.

[0064] 1.5. Examples 11-14

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com