A method for obtaining the height of the integrated chimney of the indirect air-cooled unit

A chimney height, air-cooling unit technology, applied in computer-aided design, instrument, geometric CAD, etc., can solve the problems of flue gas corrosion to the inner wall of the air-cooling tower, flue gas retention, low airflow velocity, etc., to achieve compact model, easy to operate, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

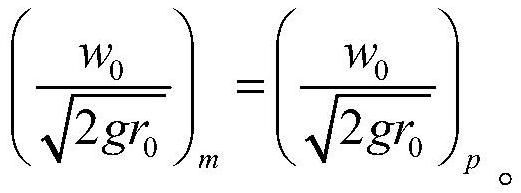

Method used

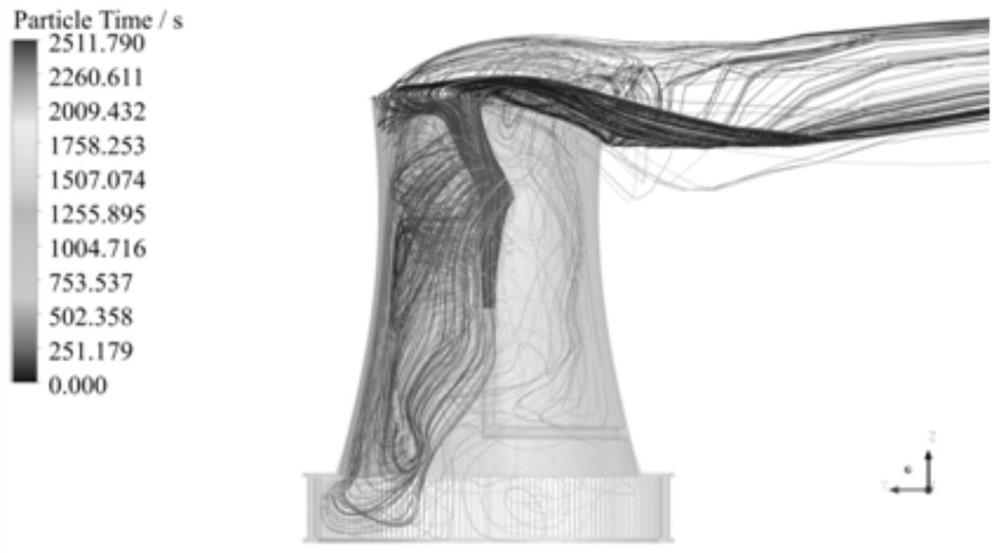

Image

Examples

Embodiment 1

[0071] Example 1: Place a chimney simulating a height of 56m in a recirculation wind tunnel, place a transparent cooling tower model in the chimney, supply heat in winter, and operate with one unit without mixing air. Tested under the conditions of 5m / s, 6m / s and 9m / s, other specific experimental parameters are shown in the table above.

Embodiment 2

[0072] Example 2: Place a simulated chimney with a height of 56m in a recirculation wind tunnel, place a transparent cooling tower model in the chimney, supply heat in winter, operate a unit, and mix air, successively at a wind speed of 5m / s, 6m / s and 9m / s conditions, other specific experimental parameters are shown in the table above.

Embodiment 3

[0073] Embodiment 3: Place the chimney with a simulated height of 56m in the recirculation wind tunnel, place the transparent cooling tower model in the chimney, supply heat in winter, and operate two units without mixing air. Tested under the conditions of 5m / s, 6m / s and 9m / s, other specific experimental parameters are shown in the table above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com