Crack-resistant glued laminated bamboo

A green layer, vertical technology, applied in the field of anti-cracking bamboo lamella, can solve the problems of tearing clothes, affecting health, large cracks, etc., and achieving the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

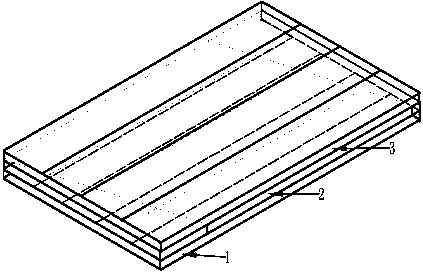

[0011] see figure 1 : A kind of anti-cracking bamboo glulam, it comprises the first bamboo base layer 1 of longitudinal placement, the second bamboo base layer 2 of obliquely placing at a certain angle, the 3rd bamboo base layer 3 of longitudinal placement, the first bamboo base layer 1 1. The second bamboo base layer 2 and the third bamboo base layer 3 placed vertically are bonded and hot-pressed to form a whole.

[0012] The angle that the second bamboo base layer 2 obliquely puts is 5 °-85 °, is good with the angle that 30 °-60 ° obliquely puts. Preferred angles are 30°, 40°, 50° or 60°.

[0013] In short, between bamboo strips, between bamboo blank layers and bamboo blank layers, or between bamboo strips and bamboo blank layers, vertical placement (vertical placement) and oblique placement at a certain angle Bamboo glulam, in other words, bamboo glulam that is placed vertically and obliquely, interlaced, bonded and formed by thermocompression is within the protection sco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com