An industrial robot that can detect the degree of joint wear in real time

An industrial robot and wear level technology, applied in the field of robots, can solve problems such as wear, damage to the service life of robot joints, and difficulty for workers to find in time, so as to ensure accuracy, inhibit the continuous expansion of wear, and delay the time of wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

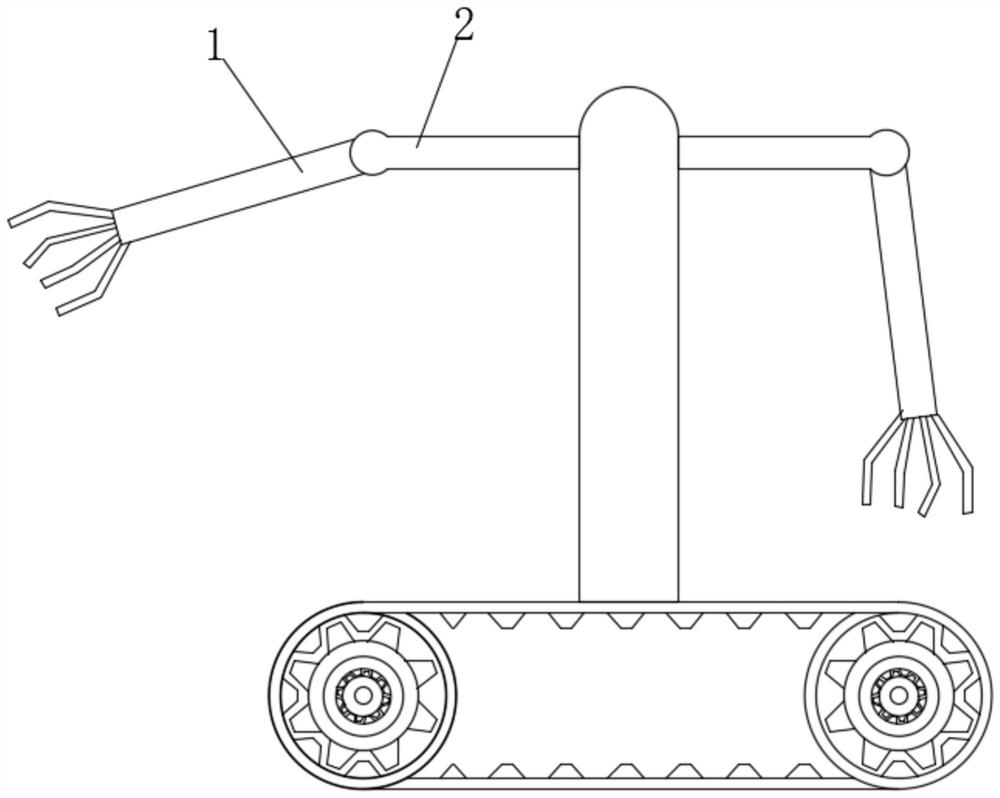

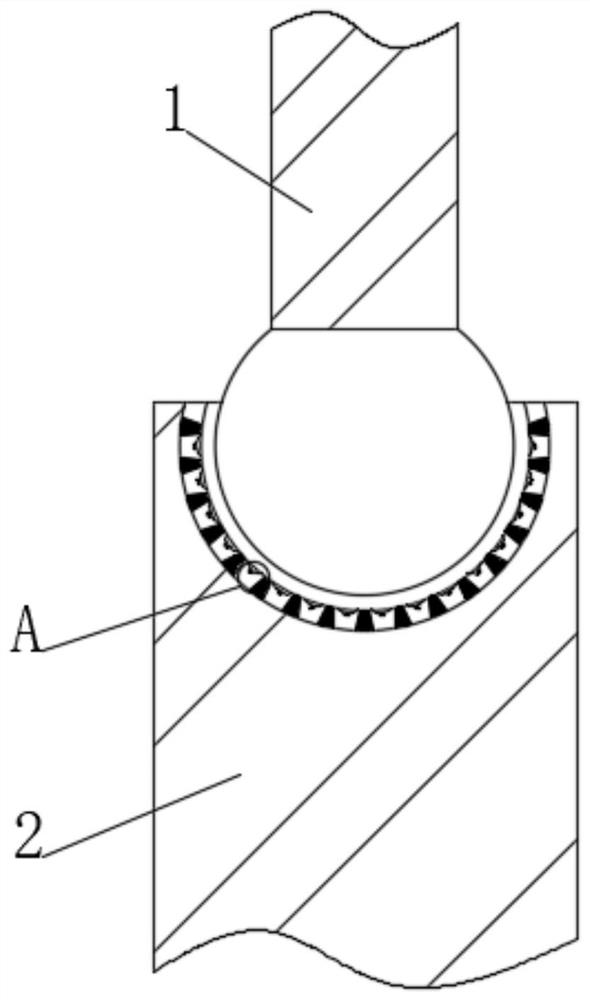

[0045] see figure 1 , an industrial robot that can detect the degree of joint wear in real time, including a robot body, a control system installed on the robot body, and a data acquisition module. The data acquisition module is connected to the control system signal, and the robot body is connected with a manipulator. 2. The joint socket 2 is connected to the articular head 1 externally.

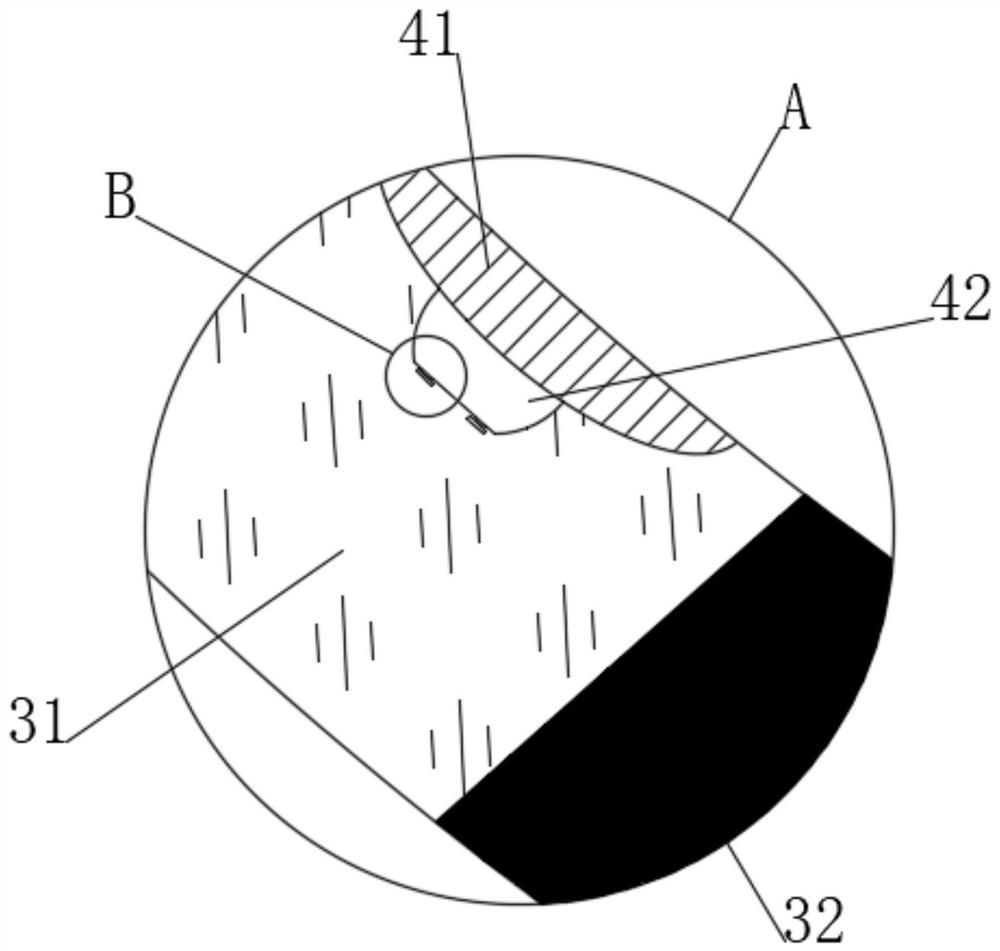

[0046] see Figure 2-3 , the inner wall of the joint fossa 2 is provided with a fixed-point detection layer, the fixed-point detection layer includes a plurality of balance detection layers 31 and pre-reminder layers 32 distributed alternately, the balance detection layer 31 and the pre-reminder layer 32 are fixedly connected, and the balance detection layer 31 is close to the joint head 1 One end is provided with a stress-sensing layer, and the stress-sensing layer includes a direct force-bearing layer 41 inlaid on the surface of the balance detection layer 31 and a force-transmitting lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com