On-site preparation method of a neutron flux measuring tube power station

A technology for on-site preparation and flux measurement, applied in the field of maintenance of nuclear power plants, can solve the problems of reducing the strength and pressure resistance of the end of the neutron flux tube, and achieve the effect of ensuring the quality of preparation, the yield of finished products, and the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

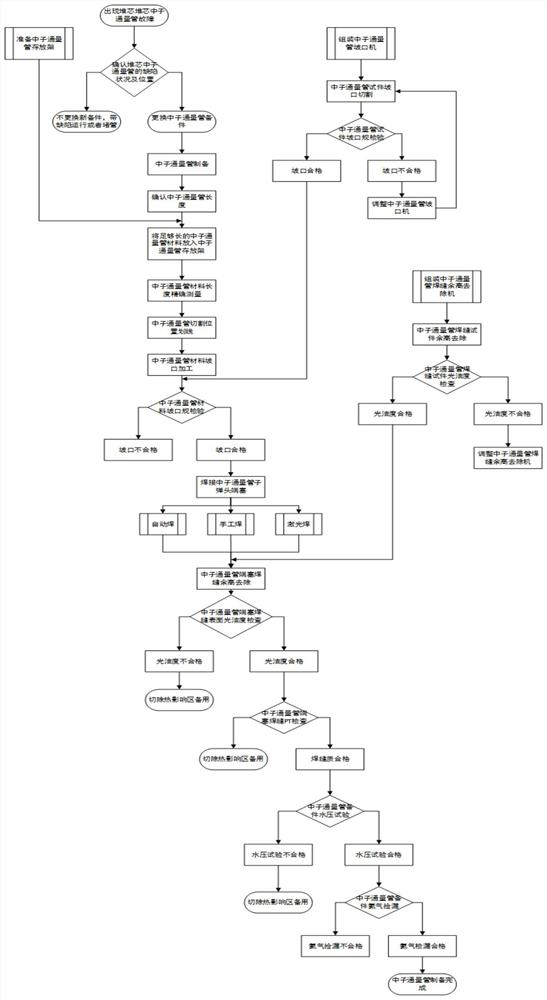

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0020] Use the profile bracket purchased on the market as the preparation bracket and storage bracket for the neutron flux tube, store the spare parts of the neutron flux measurement tube on the bracket, and measure the neutron flux tube with a grade 1E tape measure According to the preparation requirements, a margin of 2 mm is left on the neutron flux tube, and a common tube cutter is used to cut off the length. After the assembly of the pipe beveling machine is completed, use the beveling machine to verify the beveling of the pipes of the same size, model and material. The stub end of the flux tube is beveled for welding. After the groove processing is completed, the bullet head is welded to the end of the neutron flux tube by argon arc welding. After cooling, use a reinforcement removal machine to remove the weld reinforcement. After the reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com