Reciprocating plunger pump

A plunger pump, reciprocating technology, applied in the field of reciprocating plunger pumps, can solve the problems of poor working stability and high maintenance costs, reduce maintenance costs, improve stability and accuracy, and achieve stability and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

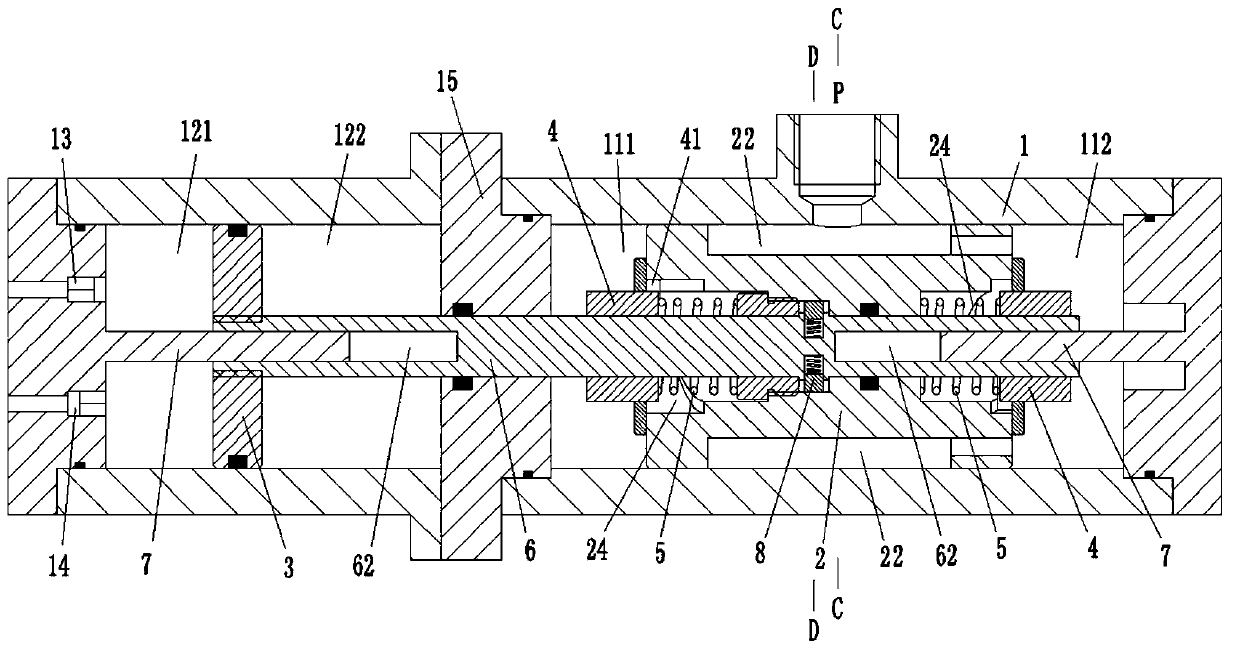

[0043] The technical solution of the present invention will be described in further detail below in conjunction with the drawings and embodiments.

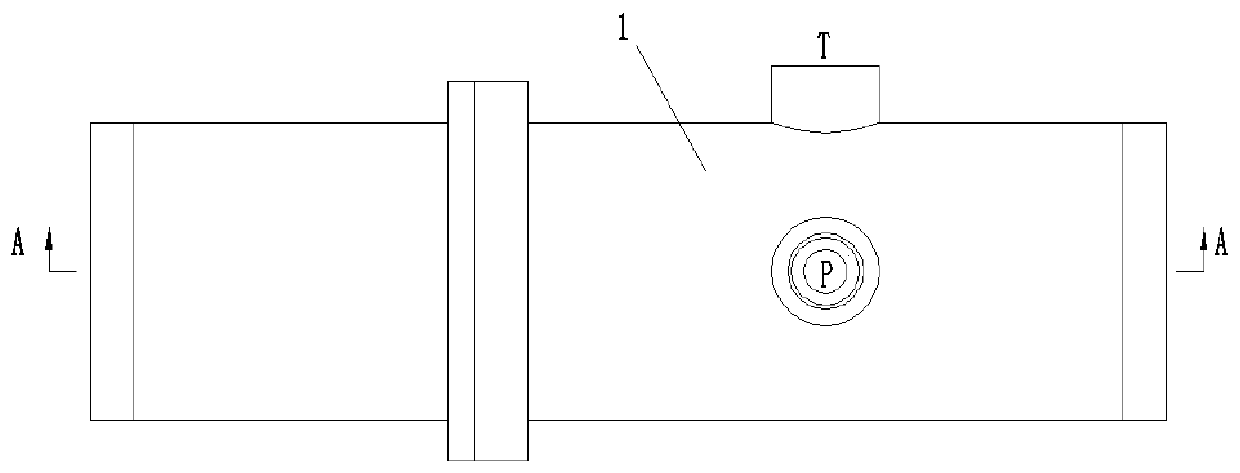

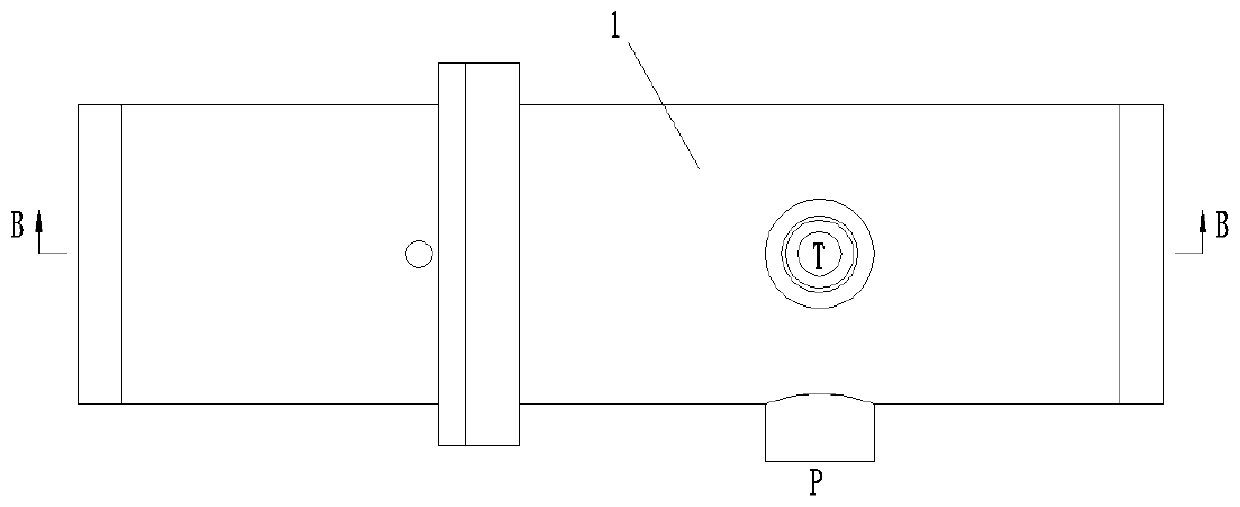

[0044] Combine Figure 1 to Figure 4 As shown, the reciprocating plunger pump of this embodiment includes a housing 1, a control piston 2 and a working piston 3. Among them, the control piston 2 and the working piston 3 are fixedly connected in the axial direction, and perform synchronous axial reciprocating movement.

[0045] The housing 1 is a hollow structure. Inside the housing 1, there are independent control chambers and working chambers, and the control chambers and working chambers are distributed along the axial direction. The housing 1 is provided with P ports, T ports, and outlets. 13 and import 14. Wherein, the P port is connected with the high-pressure oil, the T port is connected with the oil return tank, and the corresponding one-way valves are installed in the outlet 13 and the inlet 14 to realize the corresponding one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com