Carbon fiber cloth composite concrete bridge deck seamless expansion joint

A technology of carbon fiber cloth and seamless expansion and contraction, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of reducing crack growth speed and development, low availability, high price, etc., to enhance anti-reflection crack performance, prevent Creates and extends the effect of improving overall tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0043] Example 1:

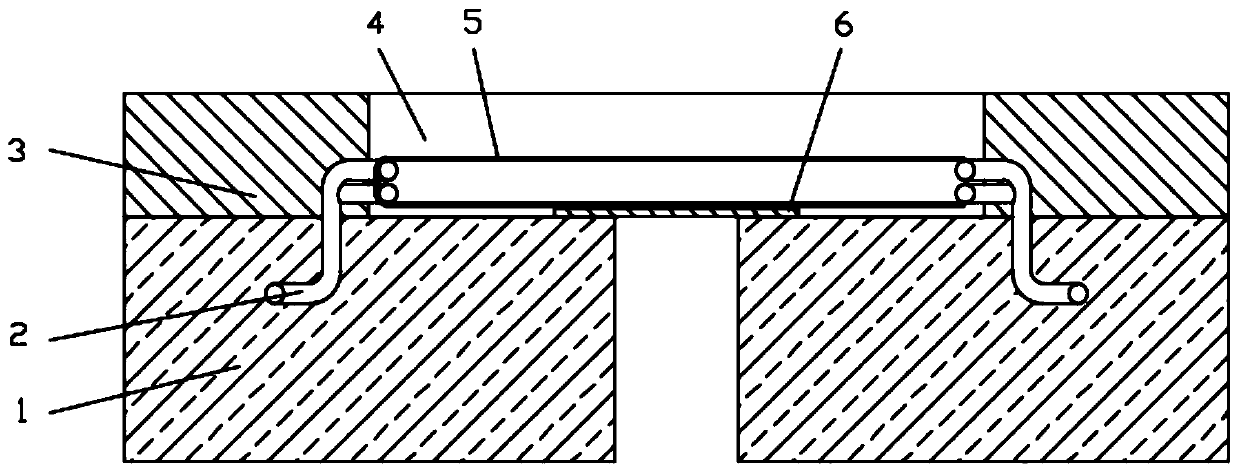

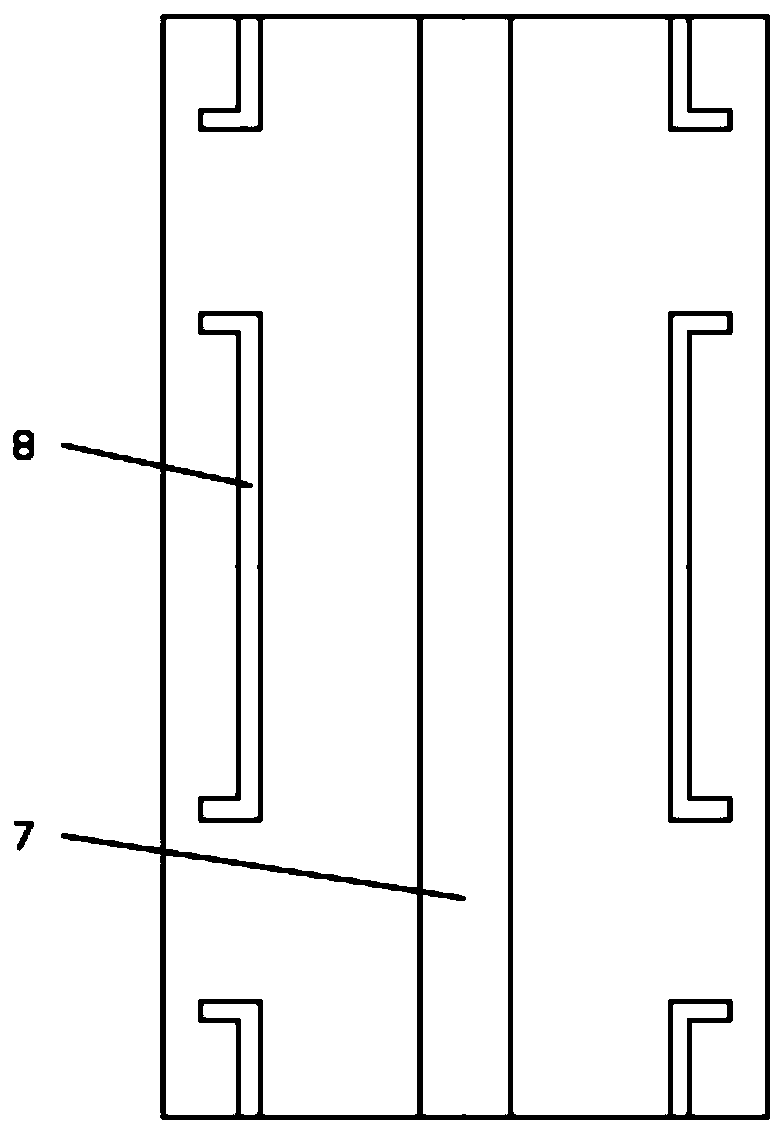

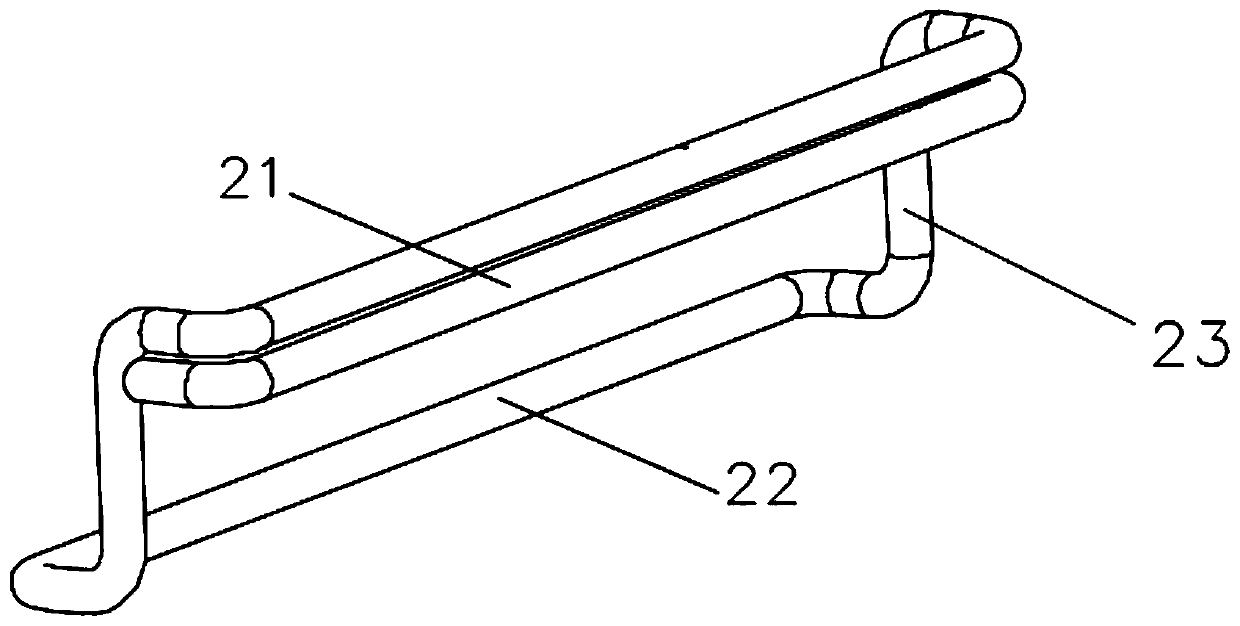

[0044] See figure 1 , figure 2 with image 3 , The present invention provides a technical solution: a carbon fiber cloth composite concrete bridge deck seamless expansion joint, including concrete bridge deck 1, steel embedded parts 2, asphalt overlay 3, expansion joint filler 4, PAN-based carbon fiber Cloth 5, steel plate 6, groove 7 and U-shaped groove 8. The concrete bridge deck 1 is placed under the asphalt overlay 3, the concrete deck 1 is placed on both sides of the trench 7, and the lower end of the embedded steel bar 2 is placed at In the concrete bridge deck 1, the upper end of the embedded steel bar 2 is set in the asphalt overlay 3. The embedded steel bar 2 includes an upper cross bar 21, a lower cross bar 22 and a vertical bar 23, an upper cross bar 21 and a lower cross bar 22 In a parallel structure, the vertical rods 23 are provided on both sides of the upper horizontal rod 21 and the lower horizontal rod 22. The upper horizontal rod 21, the low...

Example Embodiment

[0045] Example 2:

[0046] See Figure 4 , Figure 5 with Image 6 , The present invention provides a technical solution: a carbon fiber cloth composite concrete bridge deck seamless expansion joint, aimed at the structure (3 layers) of the bridge seamless expansion joint reconstruction technology when the 11cm asphalt overlay is added, including the concrete deck 1, Reinforcement embedded parts 2, asphalt overlay 3, expansion joint filler 4, PAN-based carbon fiber cloth 5, steel plate 6, groove 7 and U-shaped groove 8, concrete bridge deck 1 is set under asphalt overlay 3 , The concrete bridge deck 1 is set on both sides of the trench 7, the lower end of the steel bar embedded part 2 is set in the concrete bridge deck 1, the upper end of the steel bar embedded part 2 is set in the asphalt overlay 3, the steel bar embedded part 2 includes the upper cross The rod 21, the lower cross rod 22 and the vertical rod 23. The upper cross rod 21 and the lower cross rod 22 are in parallel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com