Nylon latch lock and inclined top combined core pulling mechanism

A technology of core-pulling mechanism and jacking machine, which is applied in the field of mold core-pulling, which can solve the problems of high processing cost and poor structural stability of inclined-top combined core-pulling mechanism, and achieve the effects of good stability, shortened processing cycle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

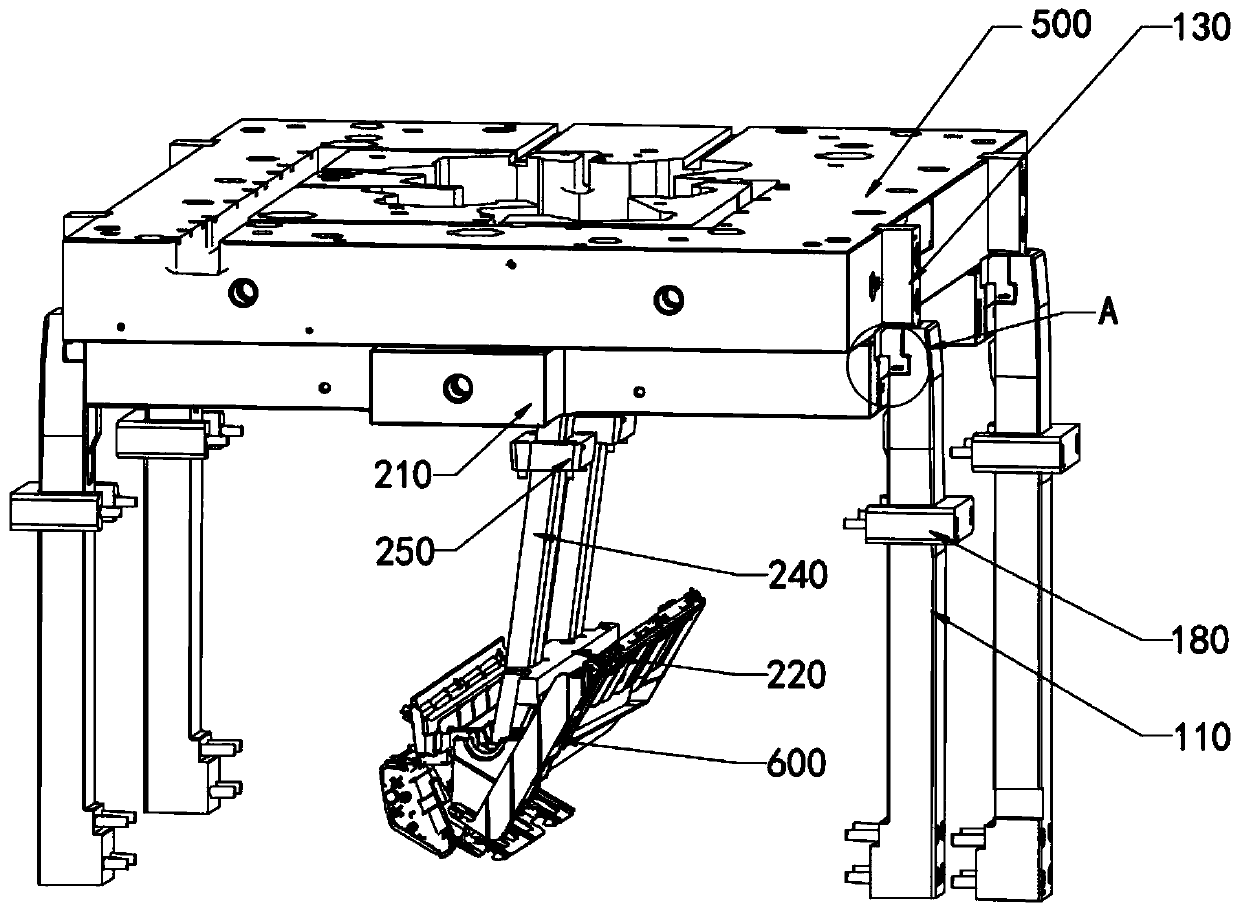

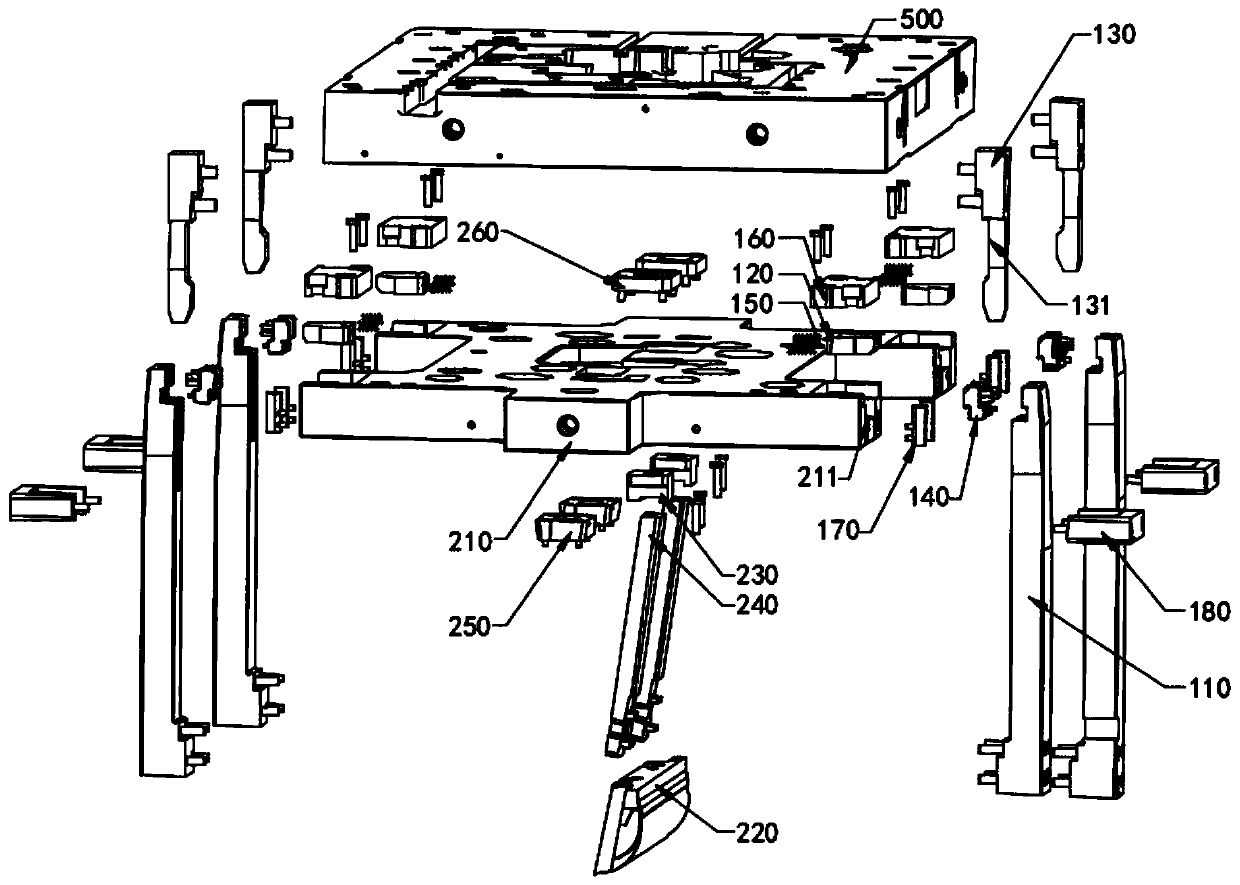

[0029] Such as Figure 1-5 As shown, the embodiment of the present invention discloses a core-pulling mechanism combined with an inclined top buckle machine, including a movable template 300, a fixed template 400, a buckle assembly and an inclined top assembly. The hot runner plate 500 above the template 400, wherein the movable template 300 is located below the fixed template 400, an accommodation space is formed between the fixed template 400 and the hot runner plate 500, and the inclined roof assembly is located In the accommodating space and the groove in the fixed template 400 .

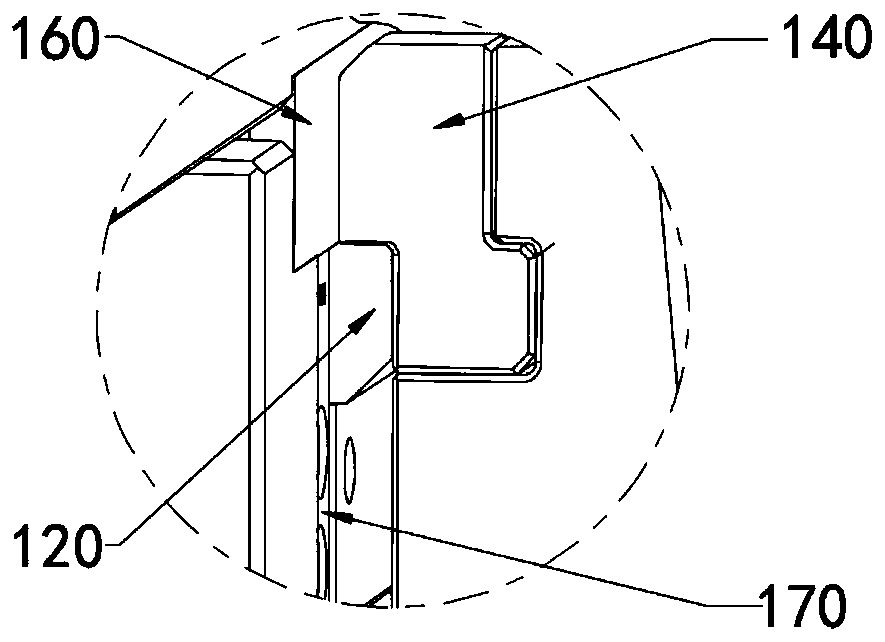

[0030] Specifically, the buckle assembly includes a buckle 110 and a buckle spring 120 , the buckle 110 extends in a vertical direction, and the vertical d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com