Pressure sleeve

A sleeve and pressure technology, applied in the field of pressure sleeves, can solve problems such as instantaneous error measurement and fault impact of manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

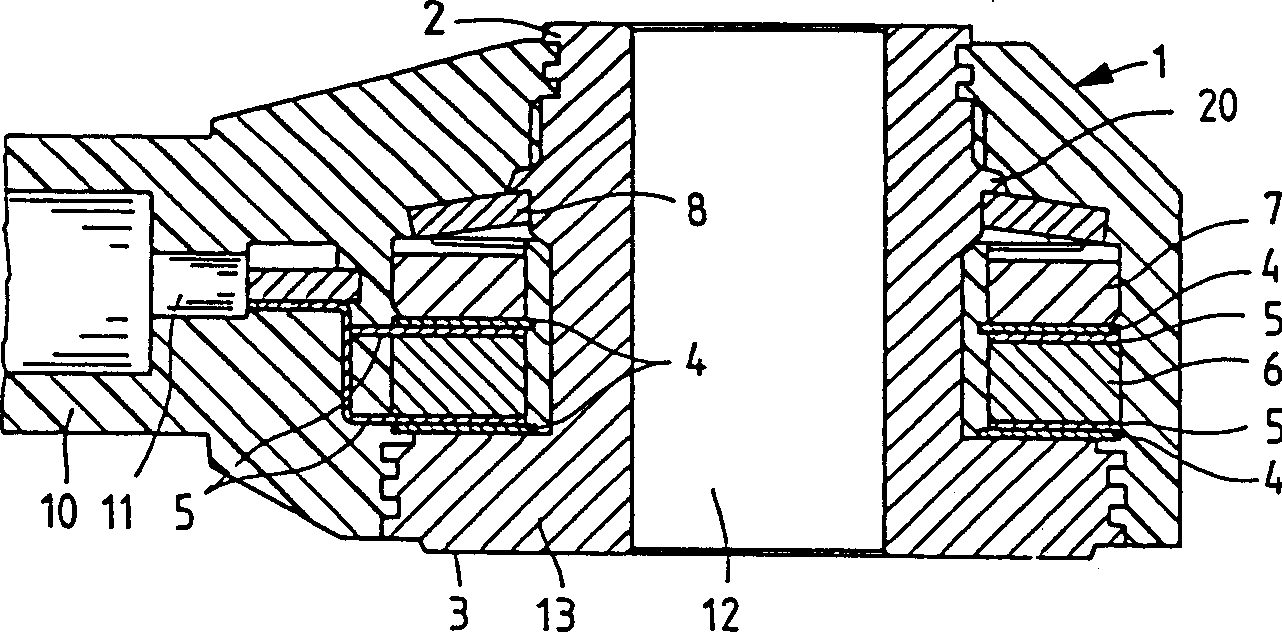

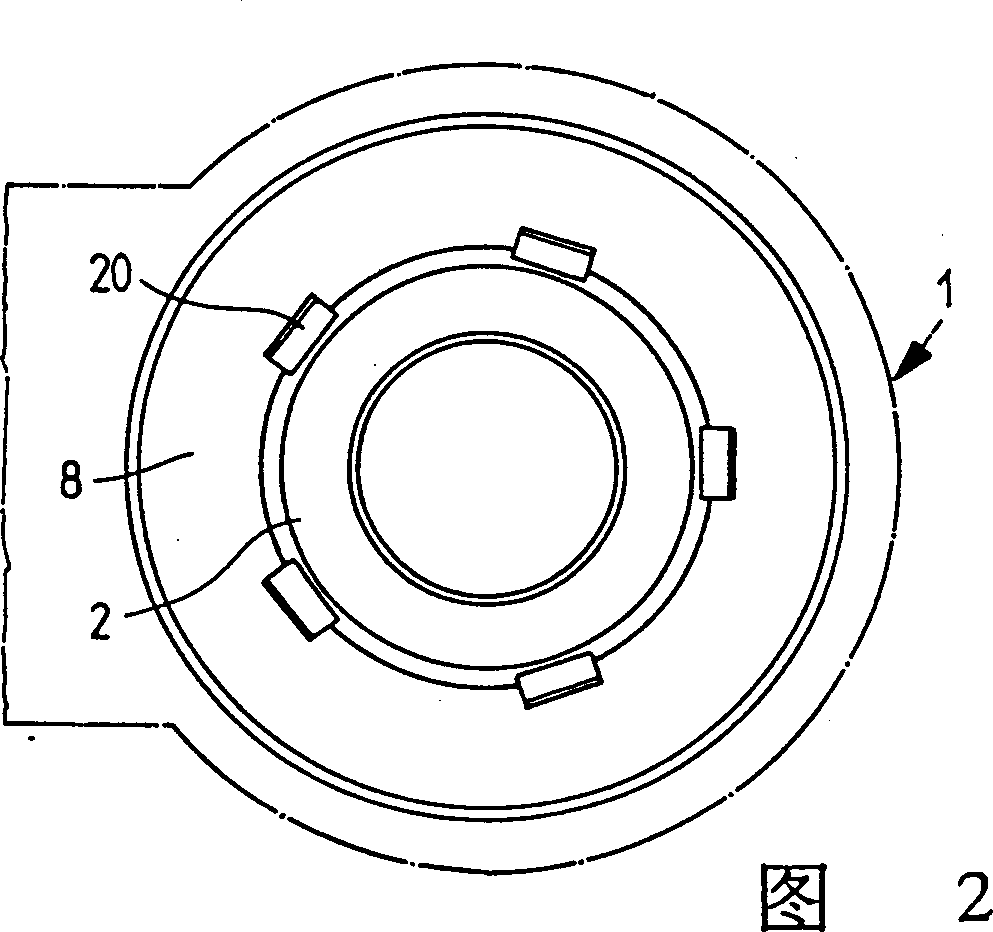

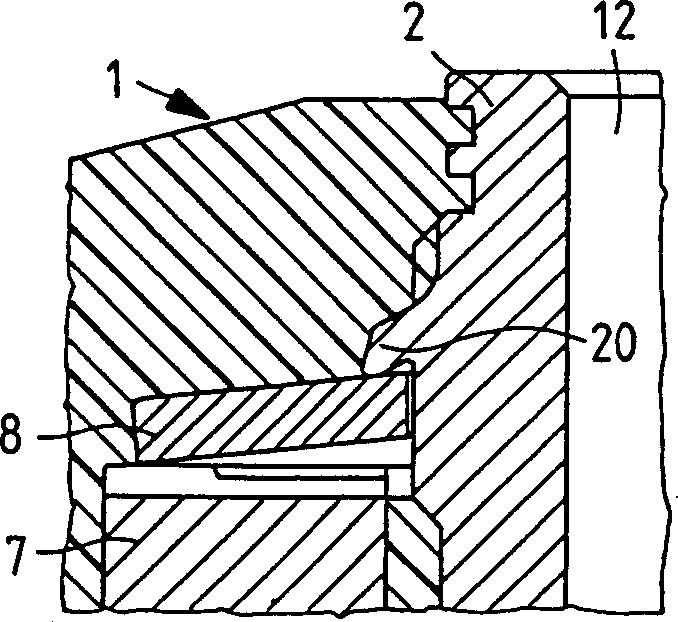

[0019] figure 1 A combustion sensor for an internal combustion engine is shown in FIG. 1 with a housing 1 in which a pressure sleeve 2 is arranged, the lower bearing surface 3 of which rests on the housing of an engine, not shown here, to detect vibrations. On the outer circumference of the pressure sleeve 2, the components arranged upward from the lower support surface 3 are: a spacer 4, a contact gasket 5, a piezoelectric ceramic sheet 6 as a detection device, and a A second contact pad 5 and a second isolation pad 4 . Located above this part is a seismic mass 7, which is pressed against the piezoceramic sheet 6 by a disc spring 8, the arched mass 20 serving as a stop for the disc spring 8, which can be seen particularly clearly in FIG. 2 see. Here, five arcuate segments are evenly distributed over the circumference of the pressure sleeve 2 .

[0020] A connecting cable 11 is inserted into an integral connecting part 10 of the plastic, in particular injection-molded housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com