Integrally-formed toothbrush with artistic hole and without copper sheet

A one-piece, copper sheet technology, applied in the field of oral care products, can solve the problems of not very firm connection, difficult to clean, and great safety, so as to achieve the goal of not easy to breed bacteria, reject copper sheet pollution, and reduce gum irritation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

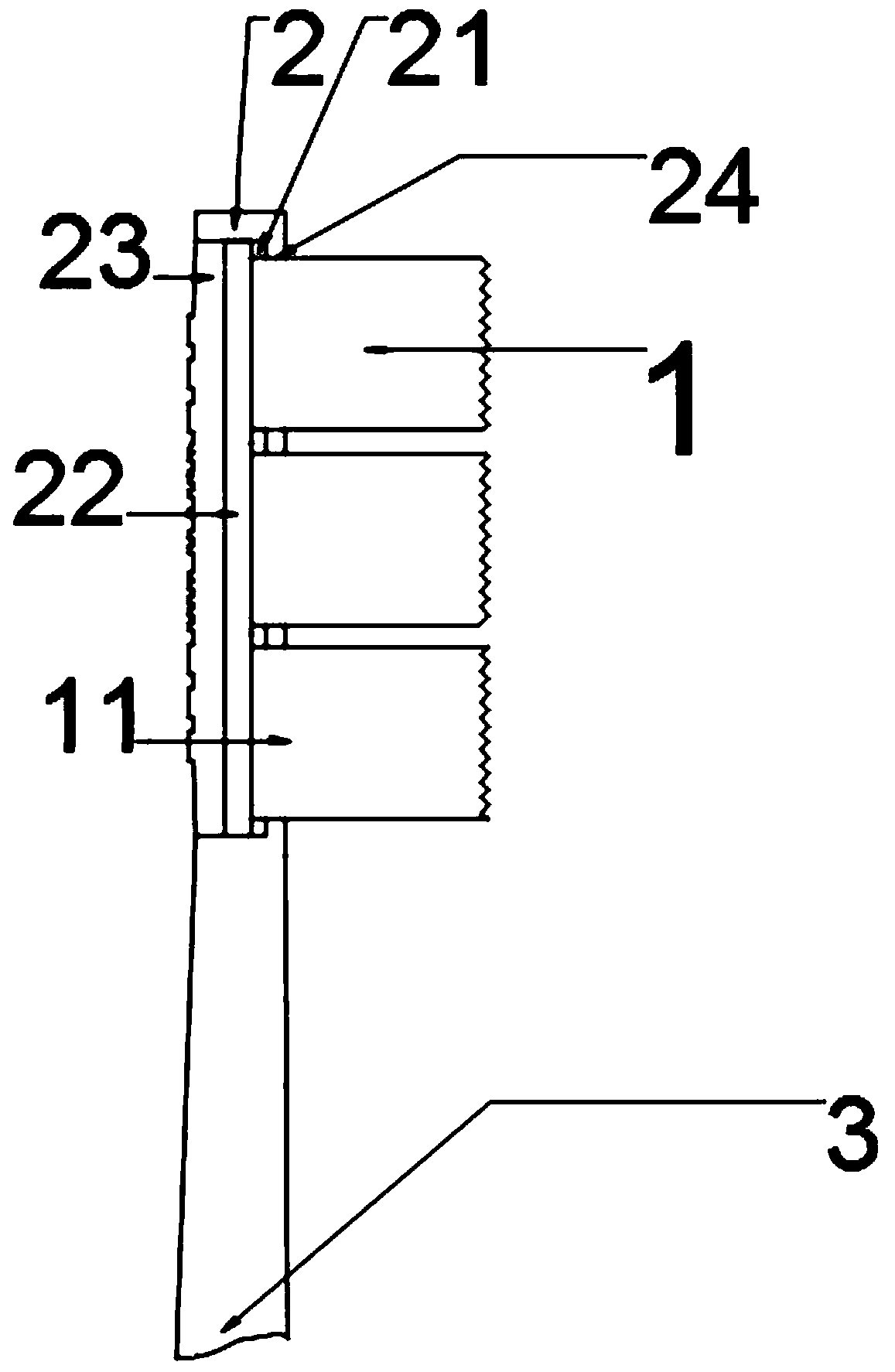

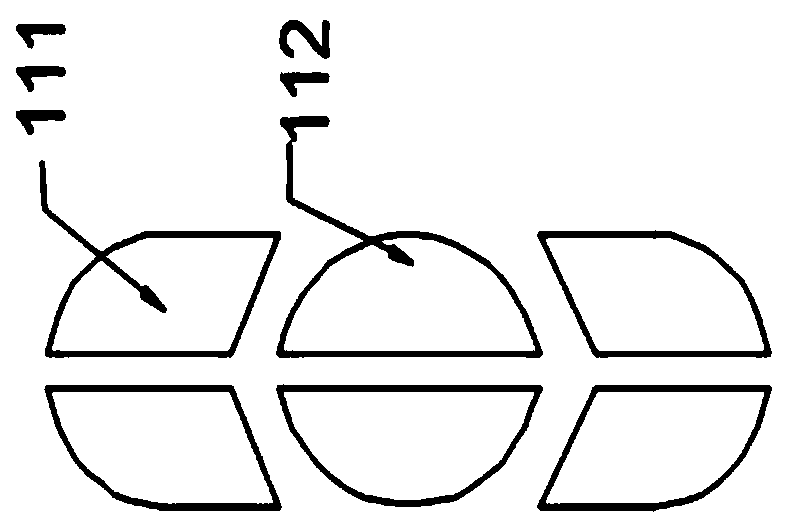

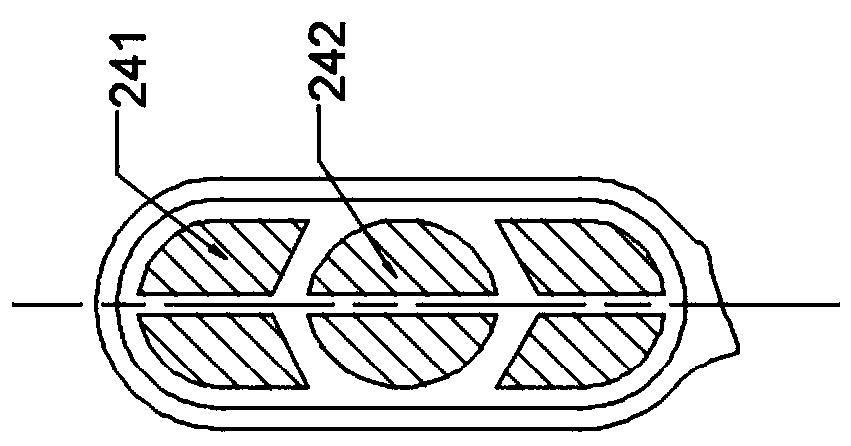

[0052] Specific implementation mode one, such as figure 2 Shown, described bristle (1) is made up of 4 1 / 4 circular art type bristle blocks (111) and 2 1 / 2 circular art type bristle blocks (112), as image 3 As shown, the special-shaped holes (24) of the brush head (2) are composed of 4 1 / 4 circular art-shaped holes (241) and 2 1 / 2 circular art-shaped holes (242). The 1 / 4 circular art-shaped holes (241) are divided into two groups, symmetrically arranged on both sides of the brush head (2) in the direction of the longitudinal axis and arranged at the two ends of the brush head (2), and in the direction of the middle longitudinal axis of the brush head (2). 2 1 / 2 circular art-shaped holes (242) are arranged symmetrically on both sides of the brush head (2), and four 1 / 4 circular art-shaped bristle blocks (111) of corresponding shapes are placed from the cavity (21) of the brush head (2) The outside of the concave bottom part of the brush is placed in 4 1 / 4 circular art-shaped...

specific Embodiment approach 2

[0054] Specific implementation mode two, such as Figure 4 As shown, the bristles (1) are composed of 2 heart-shaped art-shaped bristle blocks (113), 4 diamond-shaped art-shaped bristle blocks (114) and 2 trapezoidal art-shaped bristle blocks (115). Such as Figure 5 As shown, the special-shaped hole (24) of the brush head (2) is composed of 2 heart-shaped art-shaped holes (243), 4 diamond-shaped art-shaped holes (244) and 2 trapezoidal art-shaped holes (245), 2 heart-shaped art-shaped holes (243) are respectively distributed on the longitudinal axis at both ends of the brush head (2), next to the heart-shaped art-shaped holes (243) at both ends are arranged symmetrically are 2 diamond-shaped art-shaped holes (244 ), distributed on both sides of the longitudinal axis, and two trapezoidal holes (245) are symmetrically arranged in the middle of the brush head (2) along the longitudinal axis. 2 heart-shaped art-shaped bristle blocks (113), 4 rhombus-shaped art-shaped bristle bl...

specific Embodiment approach 3

[0055] Specific implementation mode three, such as Figure 6 As shown, the bristle (1) is composed of a 1 / 4 round art-shaped bristle block (111) and a eight-diagram-shaped art-shaped bristle block (116), as Figure 7 As shown, the special-shaped hole (24) of the brush head (2) is composed of 4 1 / 4 circular art-shaped holes (241) and 1 gossip-shaped art-shaped hole (246), and 2 1 / 4 circular art-shaped holes (246) Art-shaped holes (241) are symmetrically arranged on both sides of the brush head (2) in the direction of the longitudinal axis, and four 1 / 4 circular art-shaped holes (241) are divided into two groups and respectively arranged at both ends of the brush head (2). One Eight Diagrams-shaped art-shaped hole (246) is arranged in the longitudinal axis direction in the middle of the head (2). Place 4 1 / 4 round art-shaped brush blocks (111) and 1 gossip-shaped art-shaped brush blocks of corresponding shapes from the outside of the concave bottom part of the placement cavity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com