Axial rod piece elastic coupling

A technology of elastic couplings and rods, applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve the fatigue damage of components, affect the performance and service life of couplings, axial displacement, radial Displacement can not meet the needs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

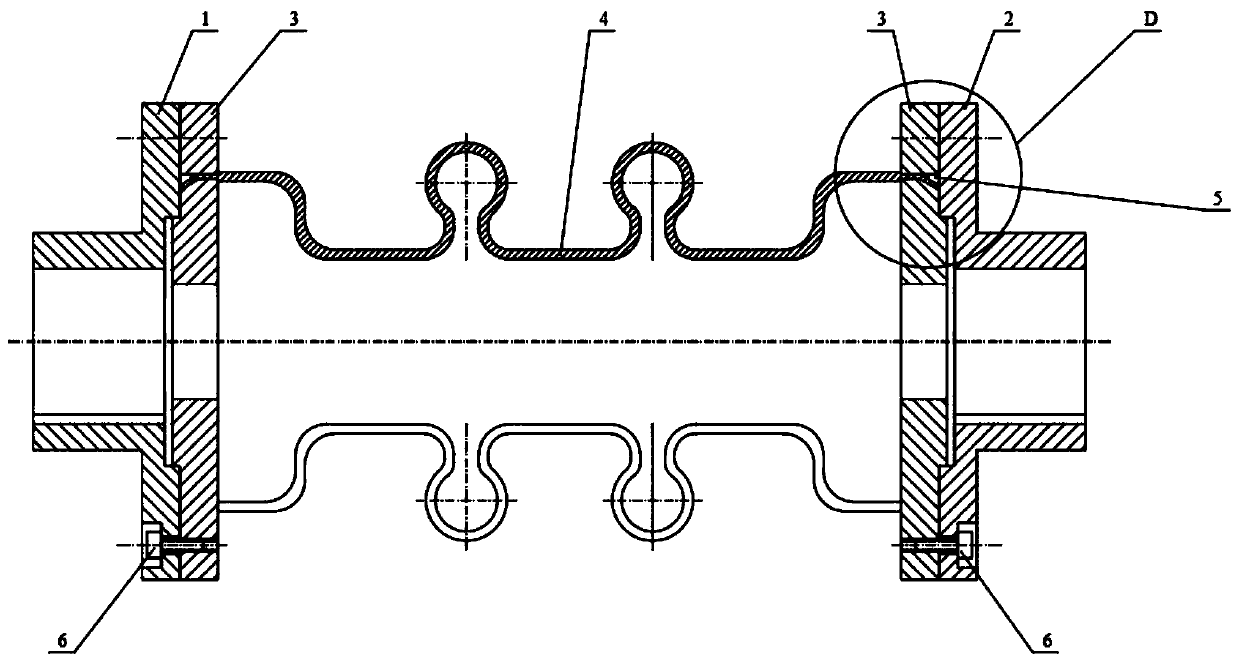

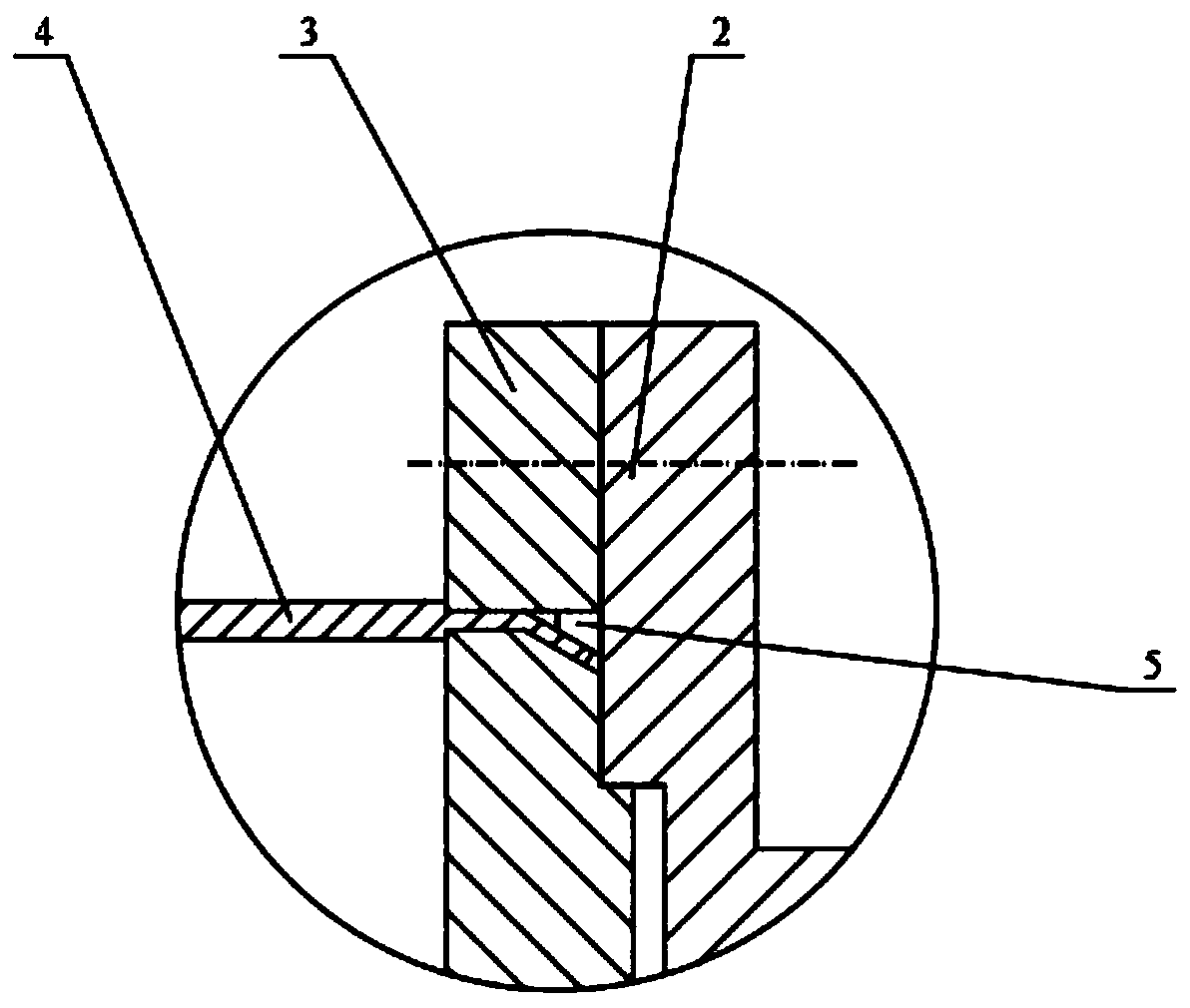

[0042] Embodiment 1, reference figure 1 , figure 2 , Figure 26 , Figure 27 , Figure 32 , Figure 33 . It can be seen from the accompanying drawings that an axial rod elastic coupling consists of a first half coupling 1, a second half coupling 2, an axial rod fixing disc 3, and an Ω-shaped axial rod 4 , a fixed wedge 5, and a fixed screw 6; its characteristic is that the first half-coupling 1 and the second half-coupling 2 are respectively connected to the axial rod fixing plate 3 through the fixing screw 6, and the Ω-shaped axial rod The member 4 is fixedly connected with the fixed plate 3 of the axial rod member through the fixed wedge 5 . The Ω-shaped axial rods 4 are uniformly distributed along the circumference, and the number is 3-12. The thickness t of the Ω-shaped axial rod 4 is 2-10 mm, and the width w is 6-30 mm. The Ω-shaped axial rod 4 is an Ω-shaped axial rod structure. The upper shaft shoulder 3-1 of the axial rod fixing disk 3 is used for positionin...

Embodiment 2

[0043] Embodiment 2, refer to image 3 . It can be seen from the drawings that an axial rod elastic coupling is characterized in that the arcuate axial rod 7 is an arcuate structure. The connection mode of each component, as well as the circumferential layout of the axial rods, the number of axial rods, the thickness t and the width w are the same as in the first embodiment.

Embodiment 3

[0044] Embodiment 3, refer to Figure 4 . It can be seen from the drawings that an elastic shaft coupling for axial rods is characterized in that the U-shaped arcuate axial rod 8 is a combination of arched and U-shaped structures. The connection mode of each component, as well as the circumferential layout of the axial rods, the number of axial rods, the thickness t and the width w are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com