Pneumatic tire and method for producing same

A technology of pneumatic tires and manufacturing methods, applied to tire parts, no separate inflatable pads, tires, etc., can solve the problems of increased manufacturing time, poor tire productivity, and deterioration of tire productivity, so as to ensure puncture sealing and prevent Effect of deterioration of rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

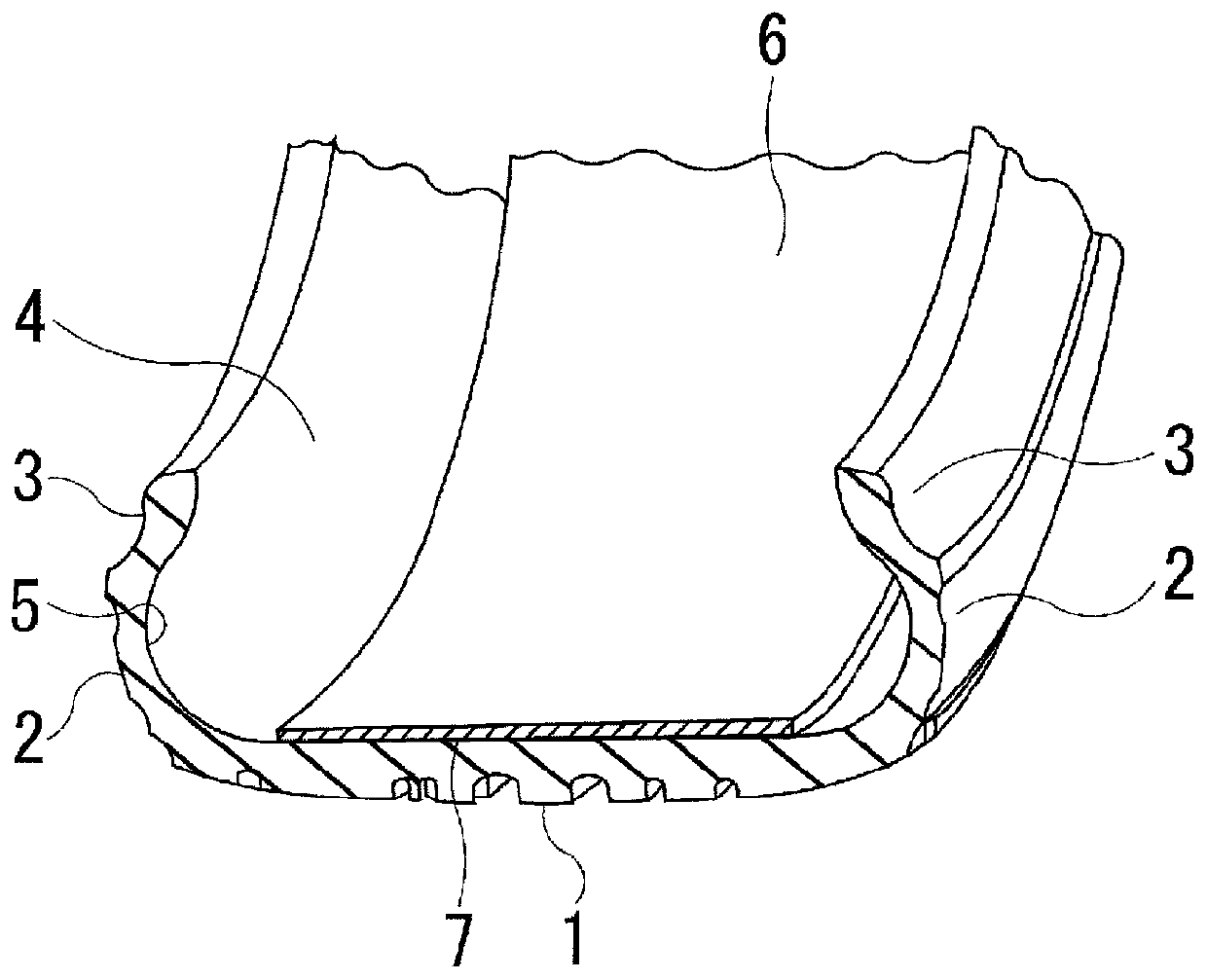

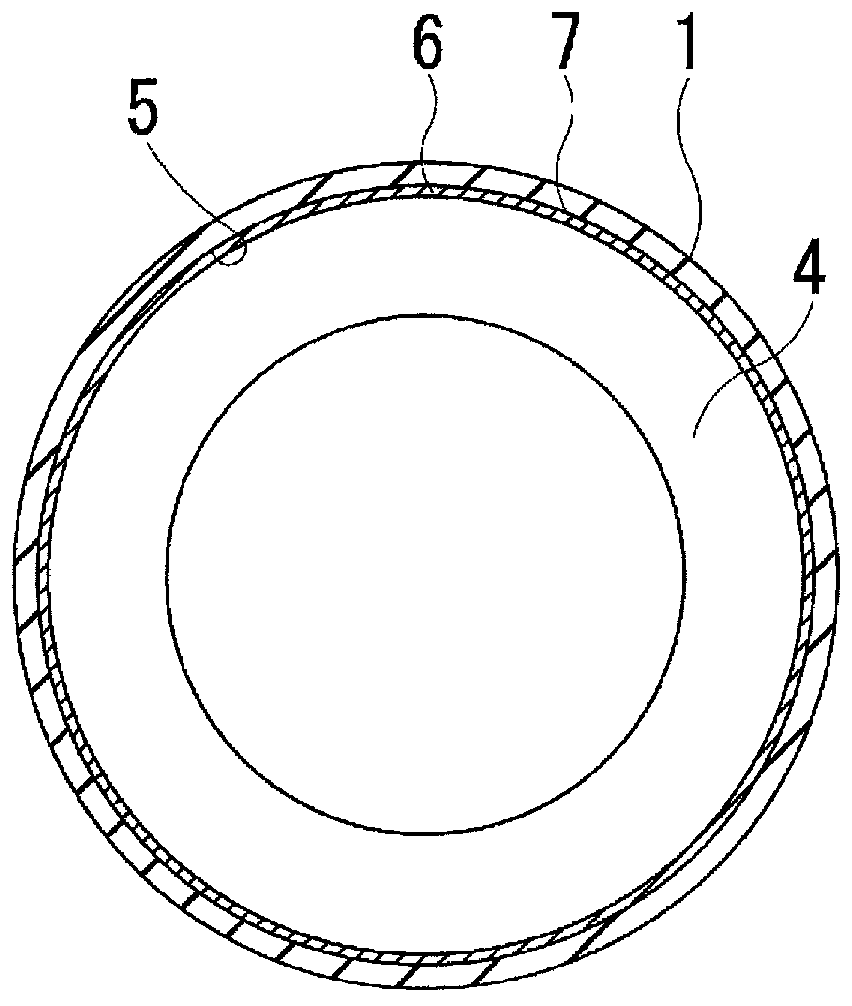

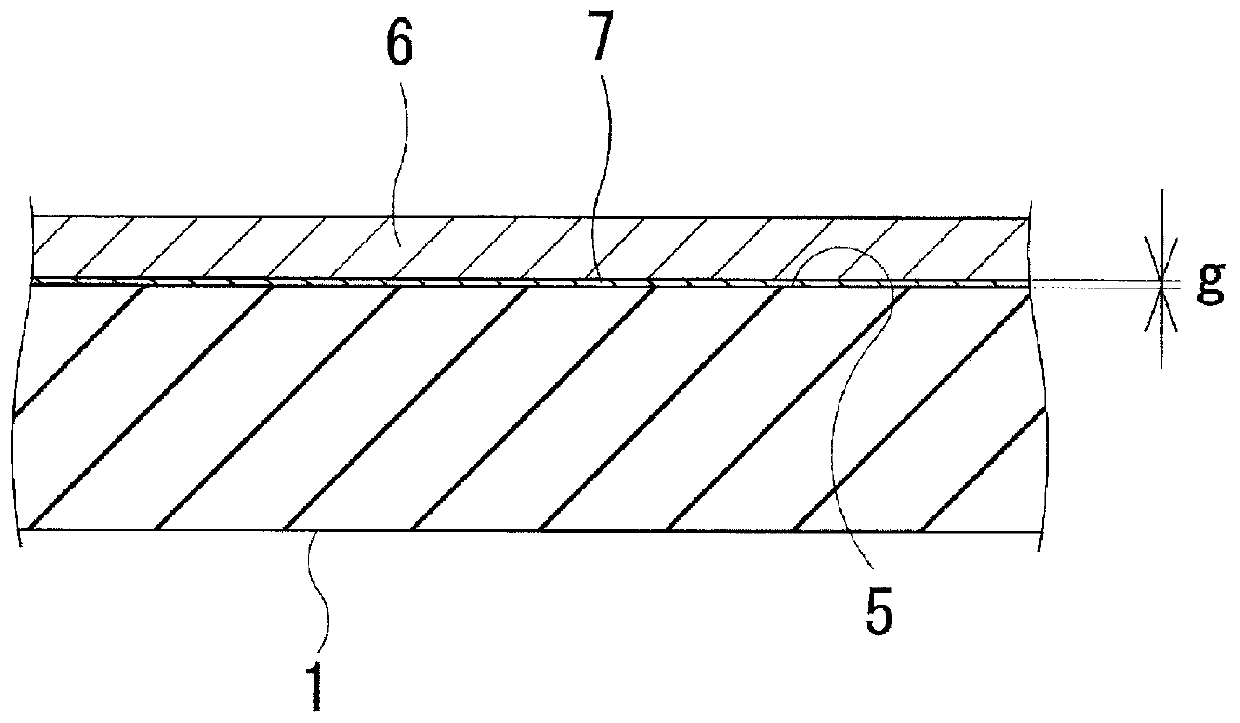

[0048] Manufactured: In a pneumatic tire having a tire size of 255 / 40R20 and a sealant layer arranged along the tire circumferential direction on the inner surface of the tread portion, the removal method of the release agent was set as shown in Table 1 and Table 2, and the method of removing the release agent into the tire was produced. Surface coating of a release agent, use of an airbag provided with a coating layer composed of a release agent during vulcanization, comparative examples 1 to 5 of the thickness (μm) of the release agent and the thickness (μm) of the sealant layer on the inner surface of the tire, and The tires of Examples 1-7.

[0049] In Comparative Example 1, a release agent was applied to the inner surface of the tire, and the removal of the release agent was not performed. In addition, in Comparative Examples 2 to 4, a mold release agent was applied to the inner surface of the tire, and the mold release agent was removed after the vulcanization process wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com