Cutting snow removing device based on large-pitch spiral line rotor

A helical and large-pitch technology, applied in snow surface cleaning, construction, cleaning methods, etc., can solve problems such as low efficiency and insufficient cutting ability, and achieve the effects of reducing difficulty, improving snow removal ability, and improving snow removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

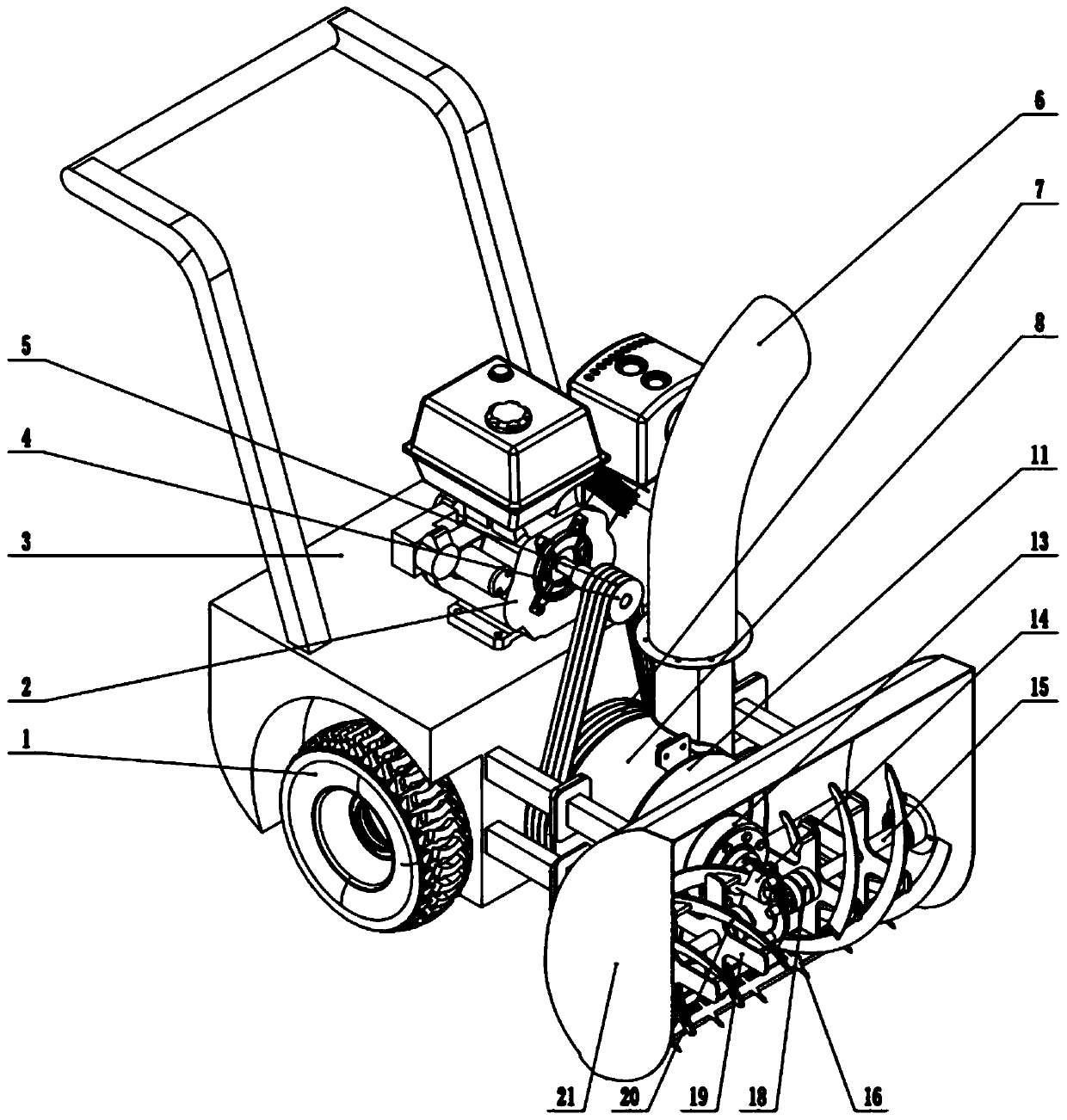

[0033] In a typical implementation of the present application, such as Figure 1-Figure 4 As shown, a cutting snow removal device based on a large-pitch helical rotor is proposed.

[0034] It includes a frame 3, which is used as the main body to carry other components, and also includes a traveling mechanism 1, a driving mechanism, a transmission mechanism, a throwing mechanism and a front-end snow removal actuator;

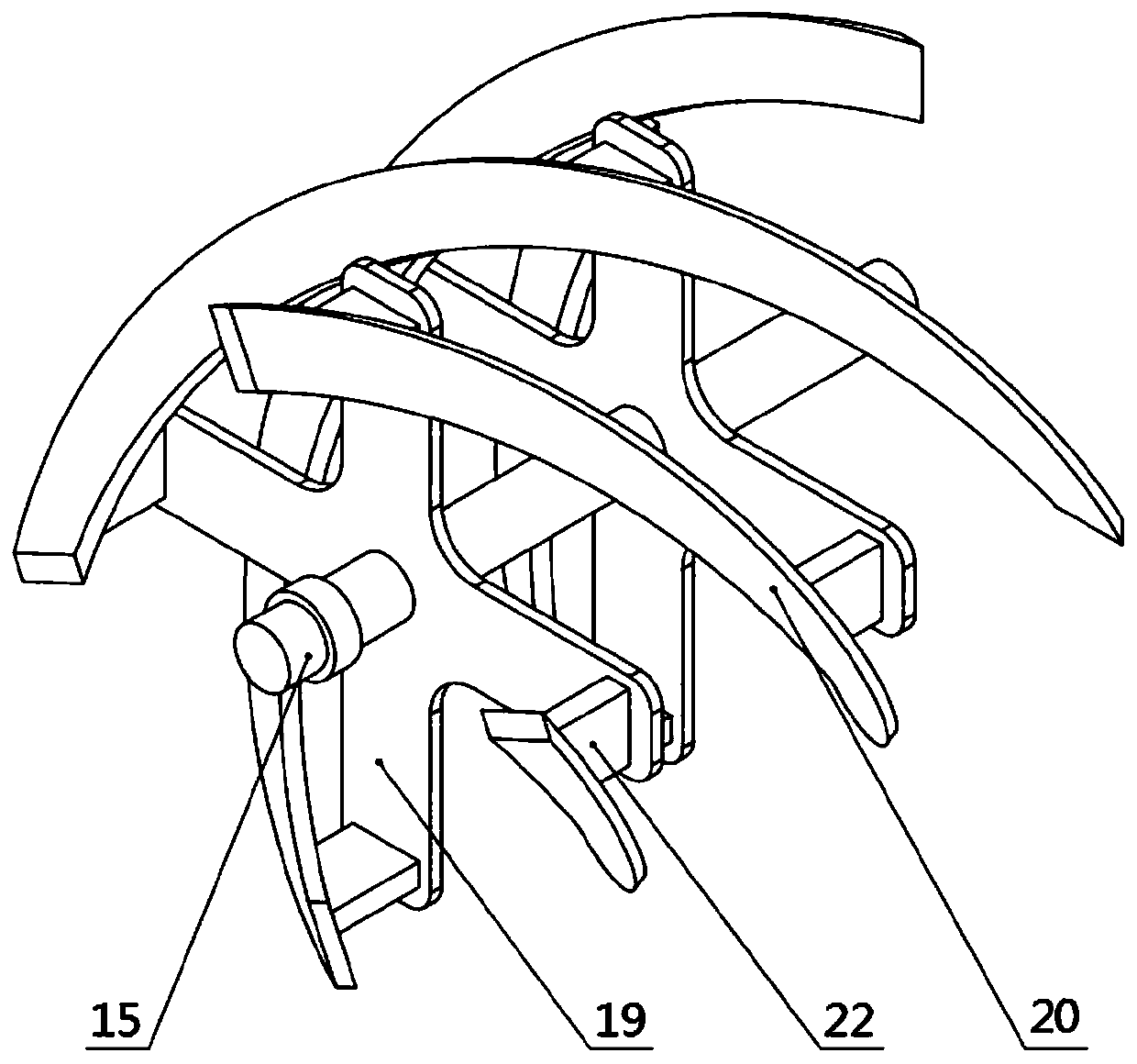

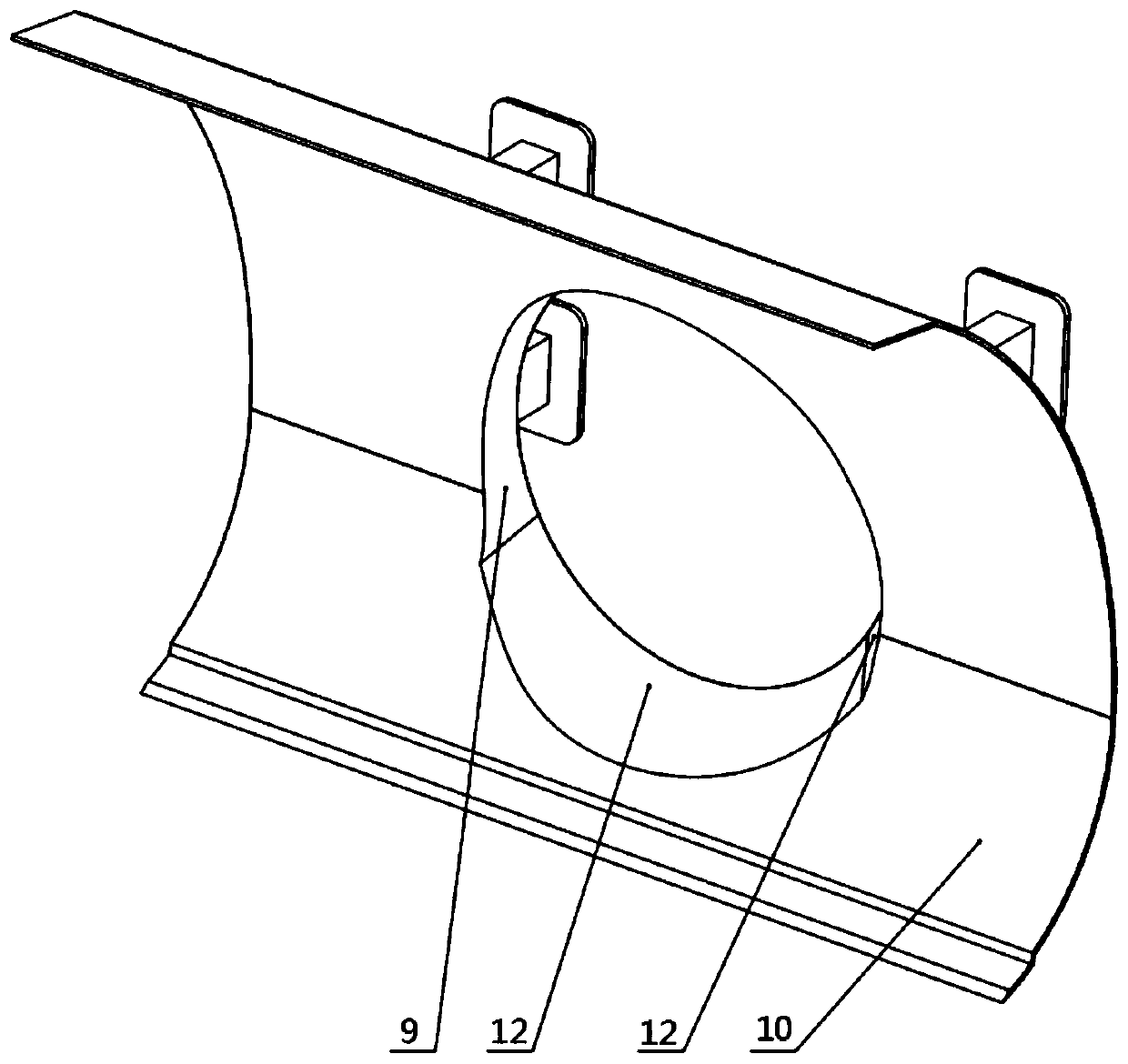

[0035] The snow removal actuator includes a snow pusher and side plates connected at its two ends, which jointly form a dustpan-shaped snow removal chamber with an open front end. The snow pusher is provided with a through hole 9, and the cavity is provided with a device that travels integrally with the device. The second shaft with a vertical direction, the second shaft is equipped with a cutter 20, and the cutter is used to rotate around the second shaft to contact and drive the snow to pass through the through hole along the arc surface of the snow pusher and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com