Method for conveniently pouring electrochromic liquid into electrochromic rearview mirror

An electrochromic and rearview mirror technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of inconvenient injection operation and high environmental vacuum requirements, and is suitable for assembly line operation and large-scale production, and the method design is ingenious , The effect of simple perfusion operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

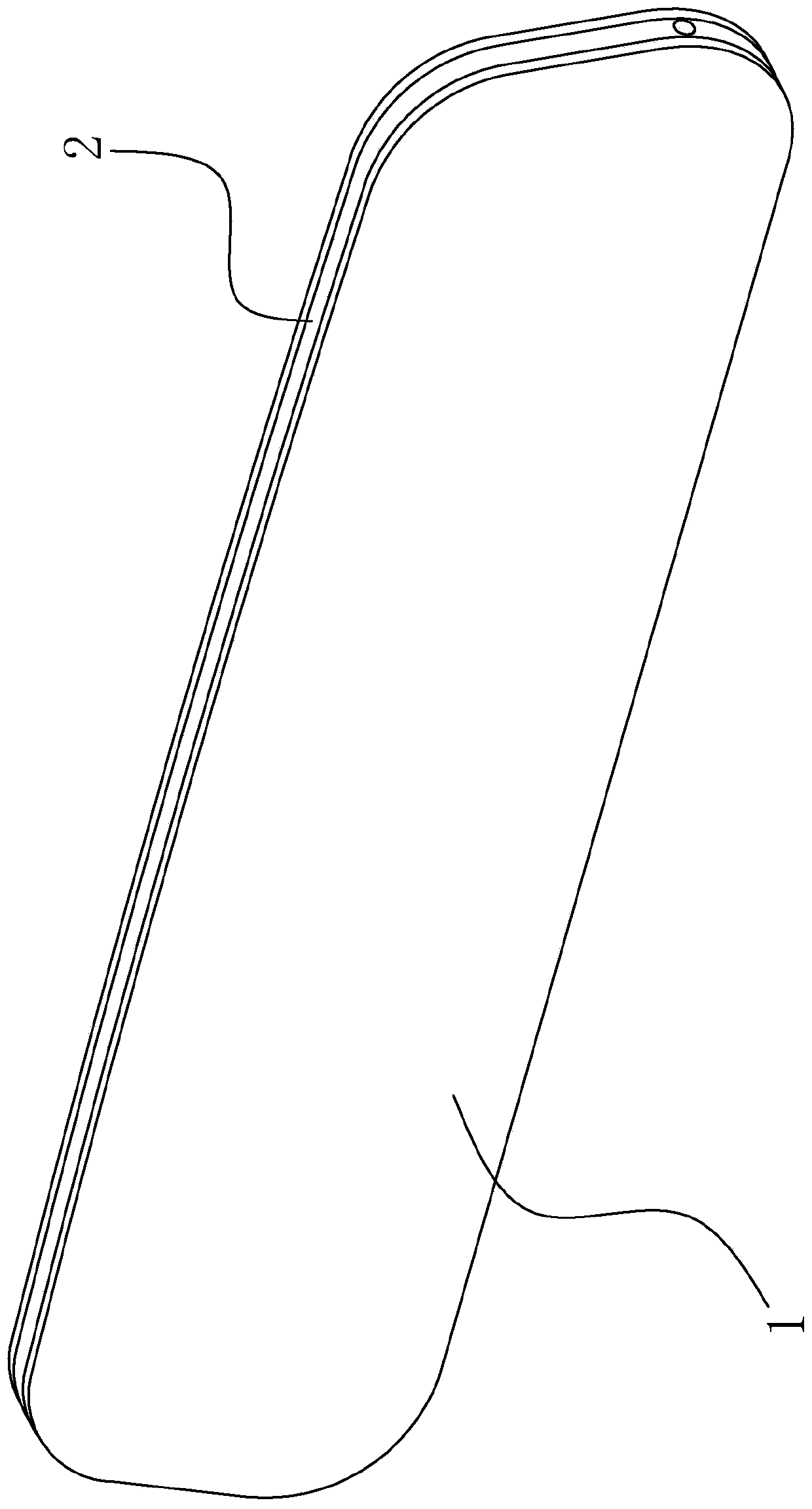

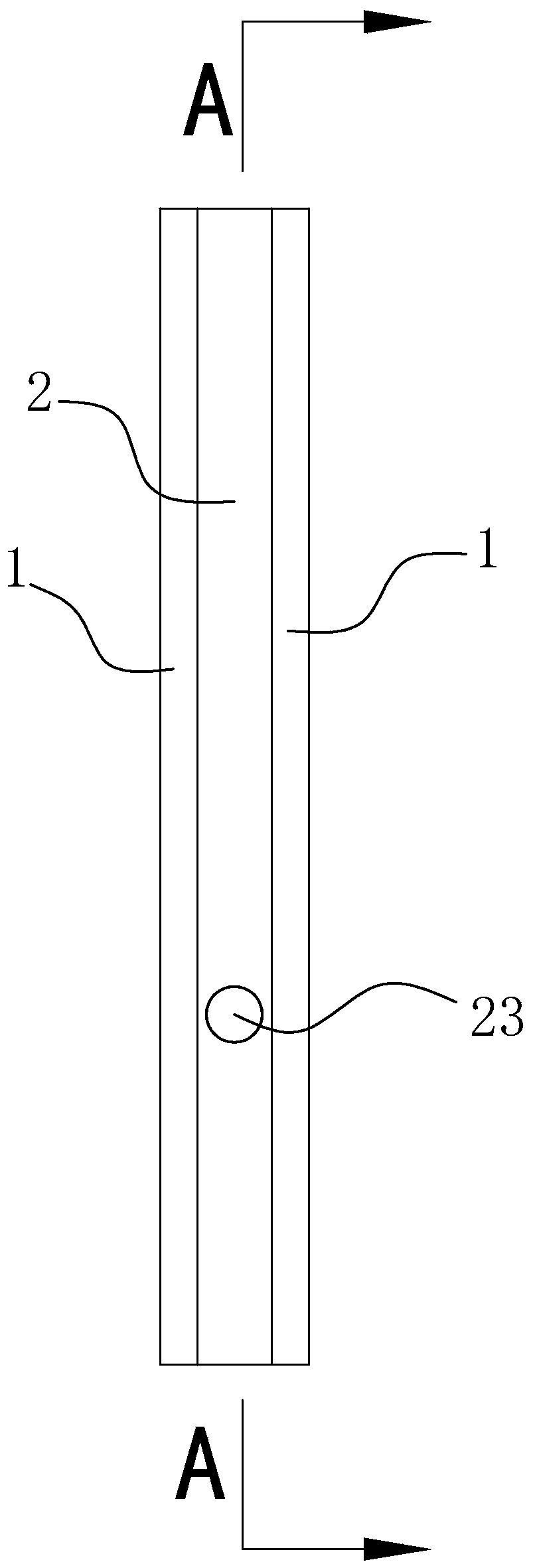

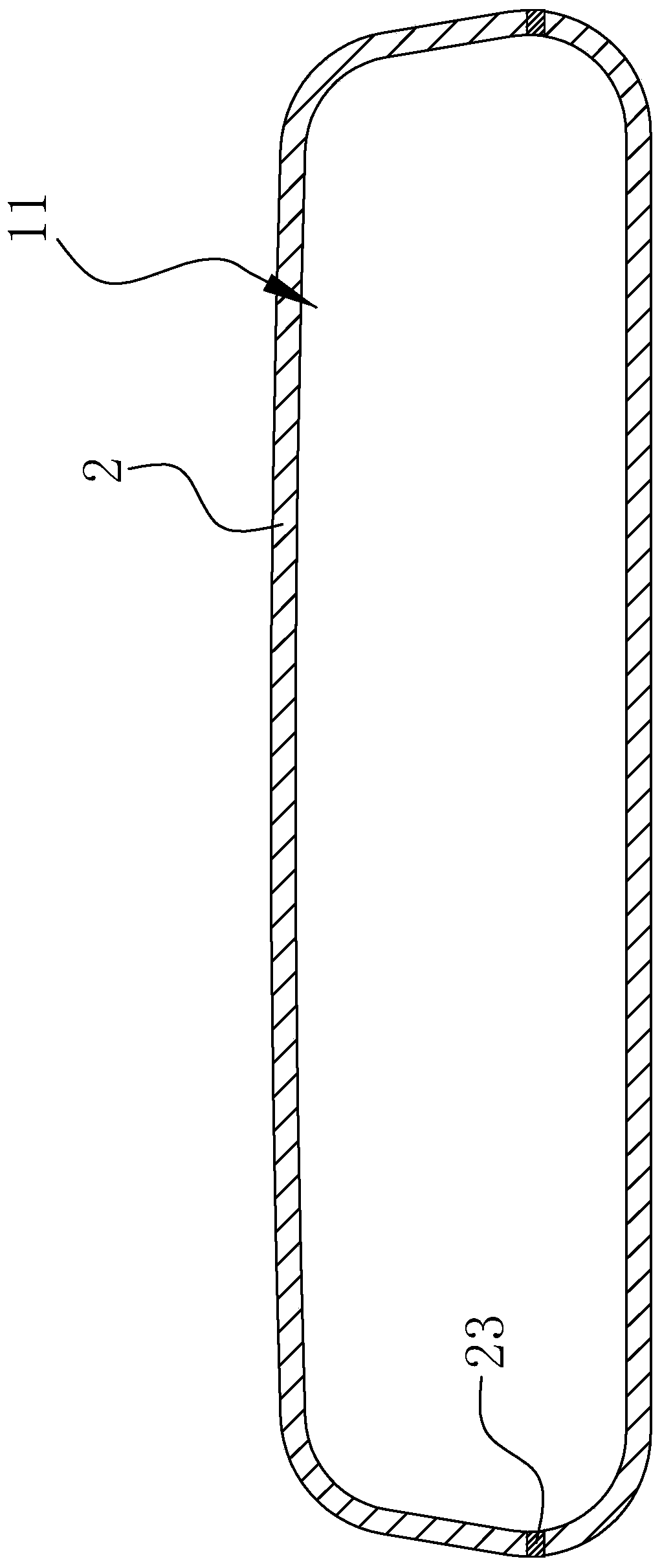

[0022] Such as Figure 1 to Figure 4 As shown, the method for conveniently filling the electrochromic liquid in the electrochromic rearview mirror of the present embodiment comprises the following steps:

[0023] 1. Make a glass shell. The glass shell is made of two front and rear glass substrates 1 bonded by epoxy resin glue 2 around the front and rear two glass substrates 1. There is a liquid inlet opening on one end of the glass shell 21. On the other end of the glass shell, there is a liquid outlet opening 22 that flows out after the electrochromic liquid fills the inner cavity of the glass shell;

[0024] 2. Remove the air in the electrochromic liquid by vacuuming the electrochromic liquid before pouring;

[0025] 3. Under the normal pressure environment, soak the liquid inlet opening 21 in the electrochromic liquid, and make the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com