Method for cooperatively cooling high-pressure ratio refrigeration compressor by diverted gas and liquid jointly entering gas supplementing port

A technology of refrigeration compressors and air supply ports, which is applied in the directions of refrigerators, compressors, refrigeration and liquefaction, etc., can solve the problem of not being able to reduce the exhaust temperature of the compressor to the allowable value, and achieve the effect of improving intelligent operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

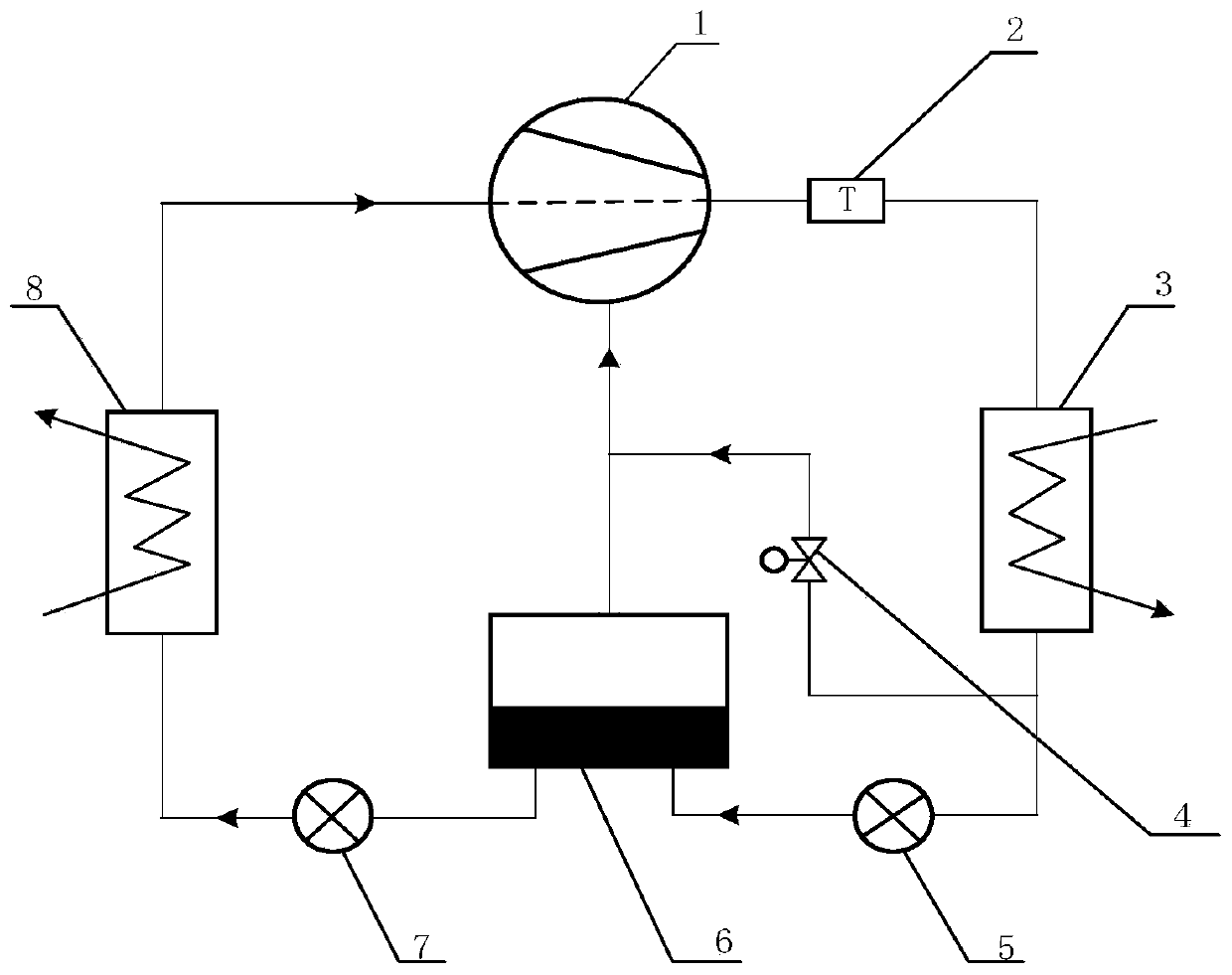

[0014] For the improvement of the throttling system before the flasher, a temperature sensor (2) is provided at the discharge port of the compressor (1), and the discharge port of the compressor (1) is then connected to the condenser (3), and the condenser (3) passes through The primary throttling element (5) is connected to the flasher (6), the gas from the flasher (6) is directly connected to the gas supply port of the compressor (1), and the liquid from the flasher (6) passes through the secondary The throttling element (7) and the evaporator (8) are connected to the air inlet of the compressor (1); at the same time, there is a drainage channel behind the condenser (3) and the flow of liquid refrigerant is controlled by the flow regulating valve (4) It is directly mixed with the gas coming out of the flasher (6) and then together with the gas supply port of the compressor (1).

[0015] When the heat pump / refrigeration cycle system is working at a high pressure ratio, the te...

Embodiment 2

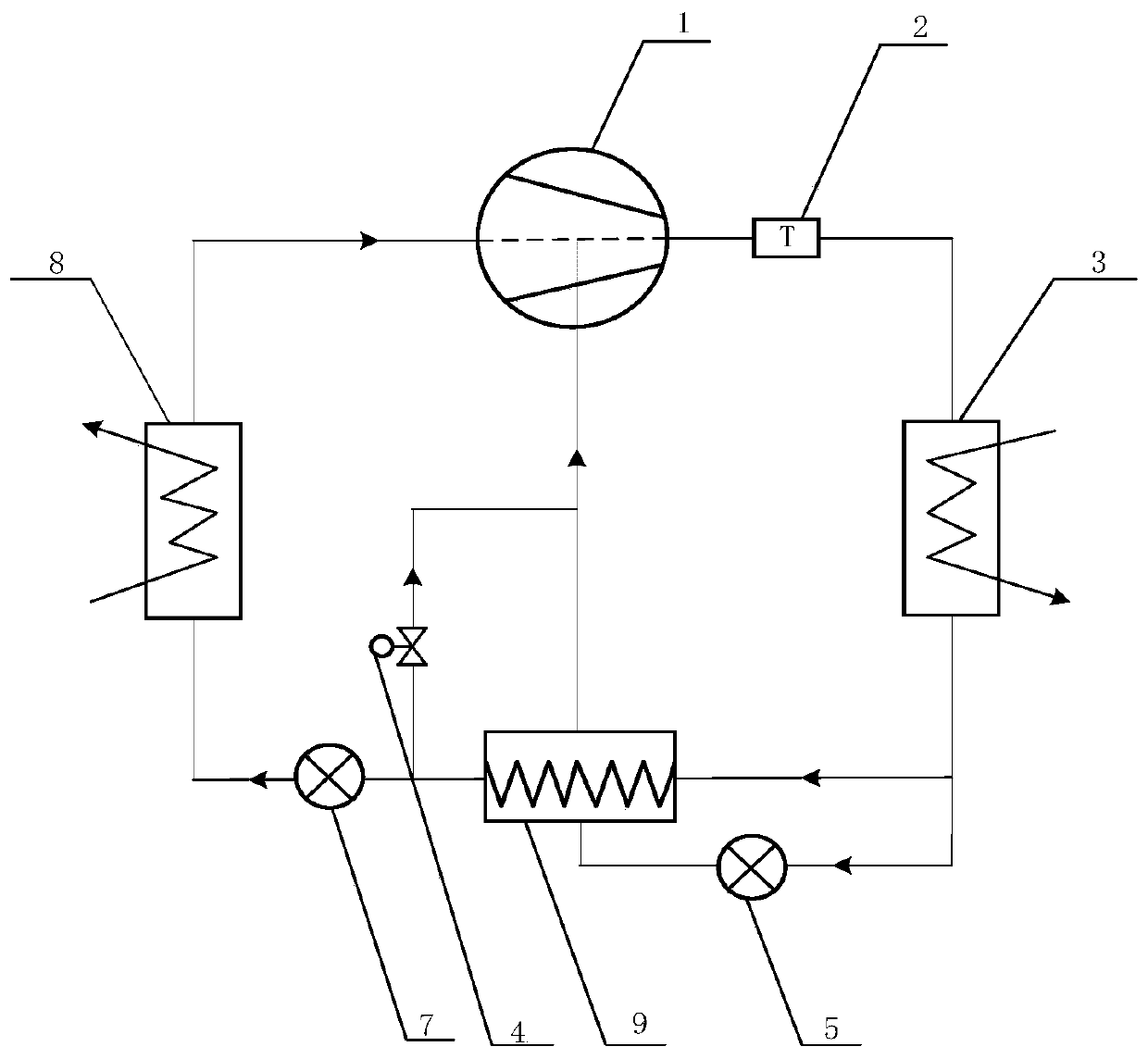

[0018] For the improvement of the subcooler system, a temperature sensor (2) is provided at the discharge port of the compressor (1), and the discharge port of the compressor (1) is then connected to the condenser (3). One inlet of the cooler (9) is connected, and the other branch after the condenser (3) is connected to the other inlet of the subcooler (9) through a primary throttling element (5), and the gas from the subcooler (9) is directly connected to the The air supply port of the compressor (1) is connected, and the liquid from the subcooler (9) is connected to the air inlet of the compressor (1) through the secondary throttling element (7) and the evaporator (8); at the same time, the subcooler The liquid coming out of (9) also has another branch flow, which is drained by the drainage channel and controlled by the flow regulating valve (4). The flow of the refrigerant liquid is directly mixed with the gas coming out of the subcooler (9), and then enters the compressor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com